The installation node and installation method of the hinged concrete prefabricated component of the support

A technology of prefabricated components and installation methods, which is applied in the field of construction engineering, can solve problems such as low installation accuracy, small operating space, and inconvenient adjustment operations, and achieve the effects of reducing installation work intensity, improving installation efficiency, and saving steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

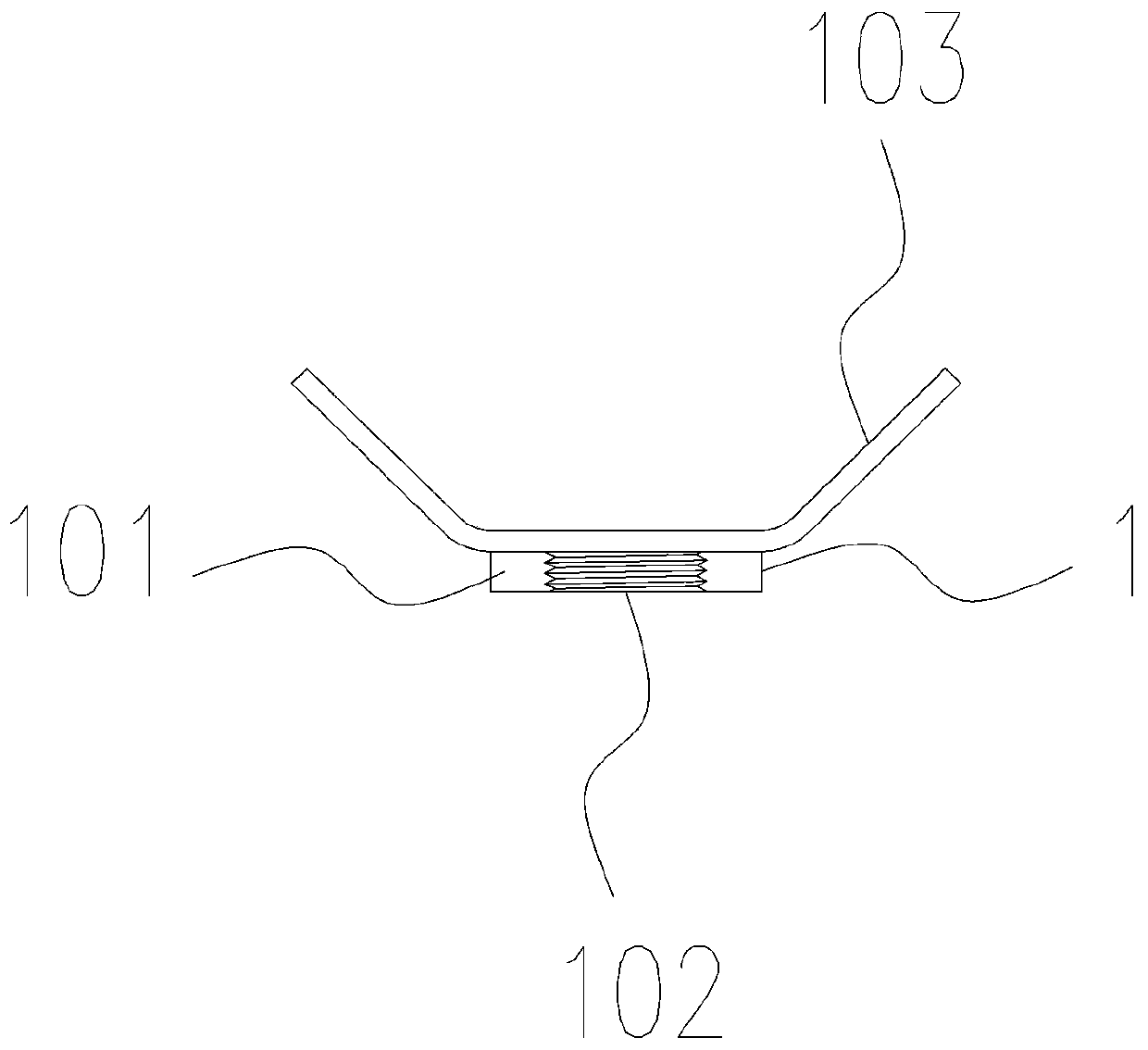

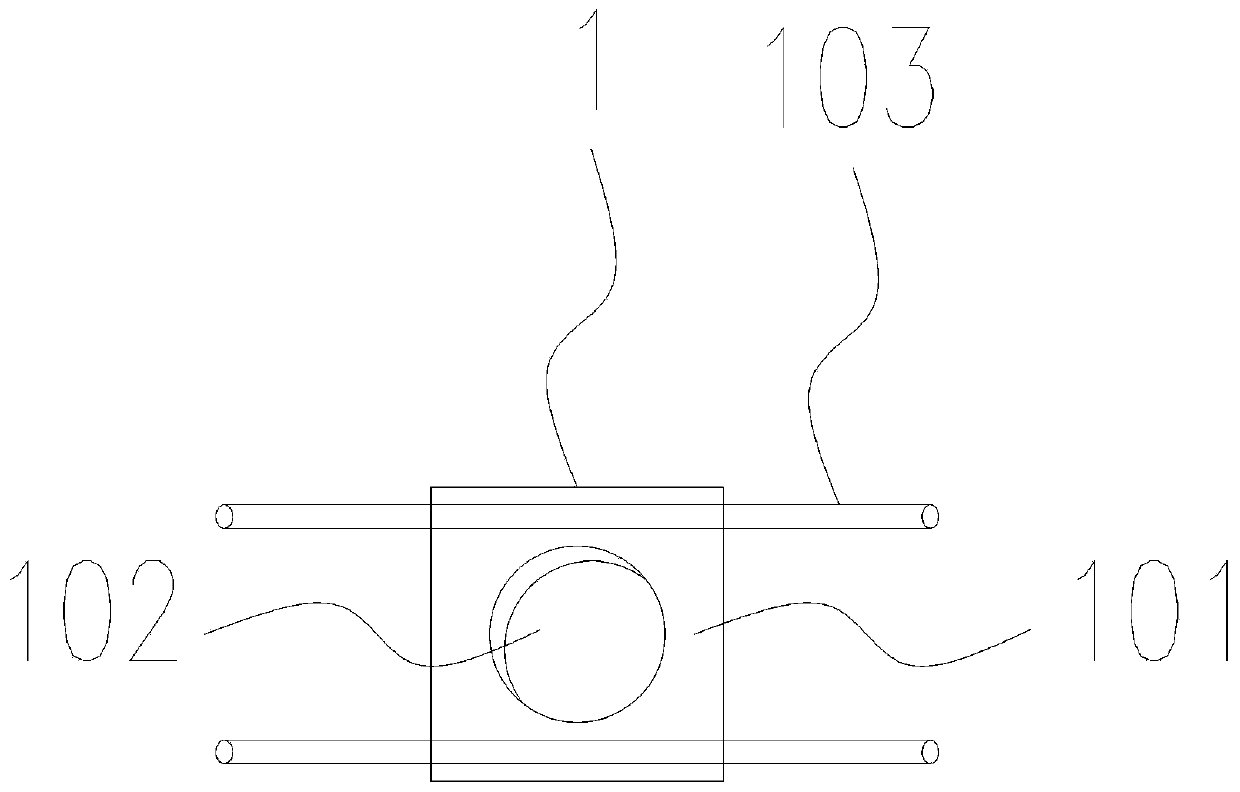

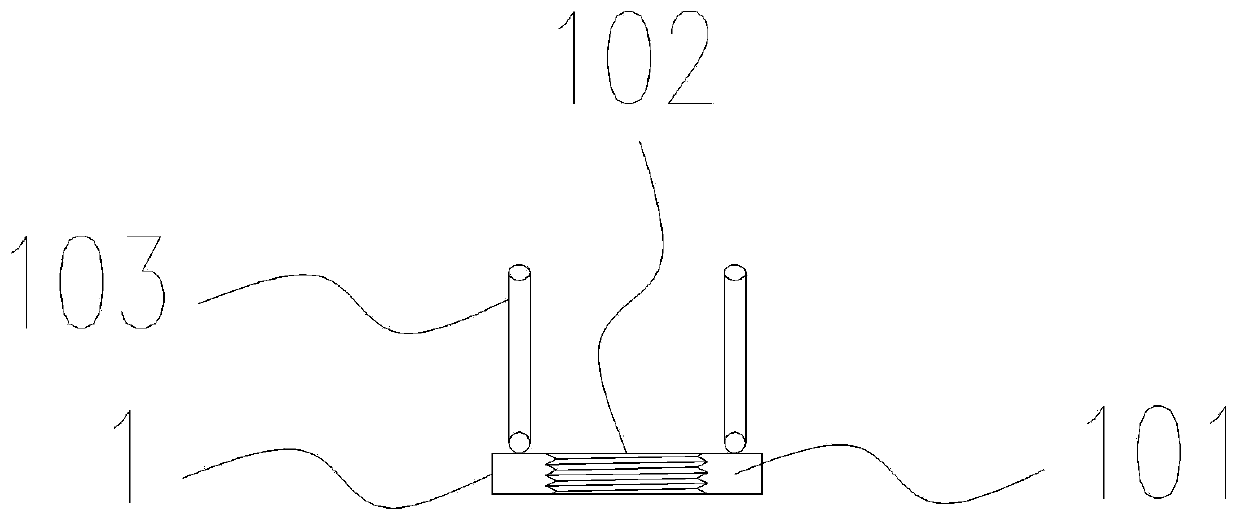

[0041] Mounting nodes for hinged concrete precast elements such as Figure 1 to Figure 12 As shown, it includes: embedded iron parts 1, suspenders 2, prefabricated concrete components 3, inverted frustum-shaped holes 4, support concrete components 5, connecting holes 6, corrugated pipes 7, mortar 8, connecting steel bars 9 and concrete grouting materials 10,

[0042]The embedded iron part 1 includes a steel plate with holes 101, an internal thread 102 and an anchoring steel bar 103; the steel plate with holes 101 is made of a steel plate with a through hole in the middle; the internal threads 102 are distributed on the steel plate with holes 101 The hole wall surface of the through hole; the anchoring steel bars 103 are welded on the same surface of the steel plate with holes 101 on both sides of the through hole;

[0043] The boom 2 includes a steel rod 201, a suspension ring 202 and an external thread 203; the steel rod 201 is made of round steel or steel pipe; the suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com