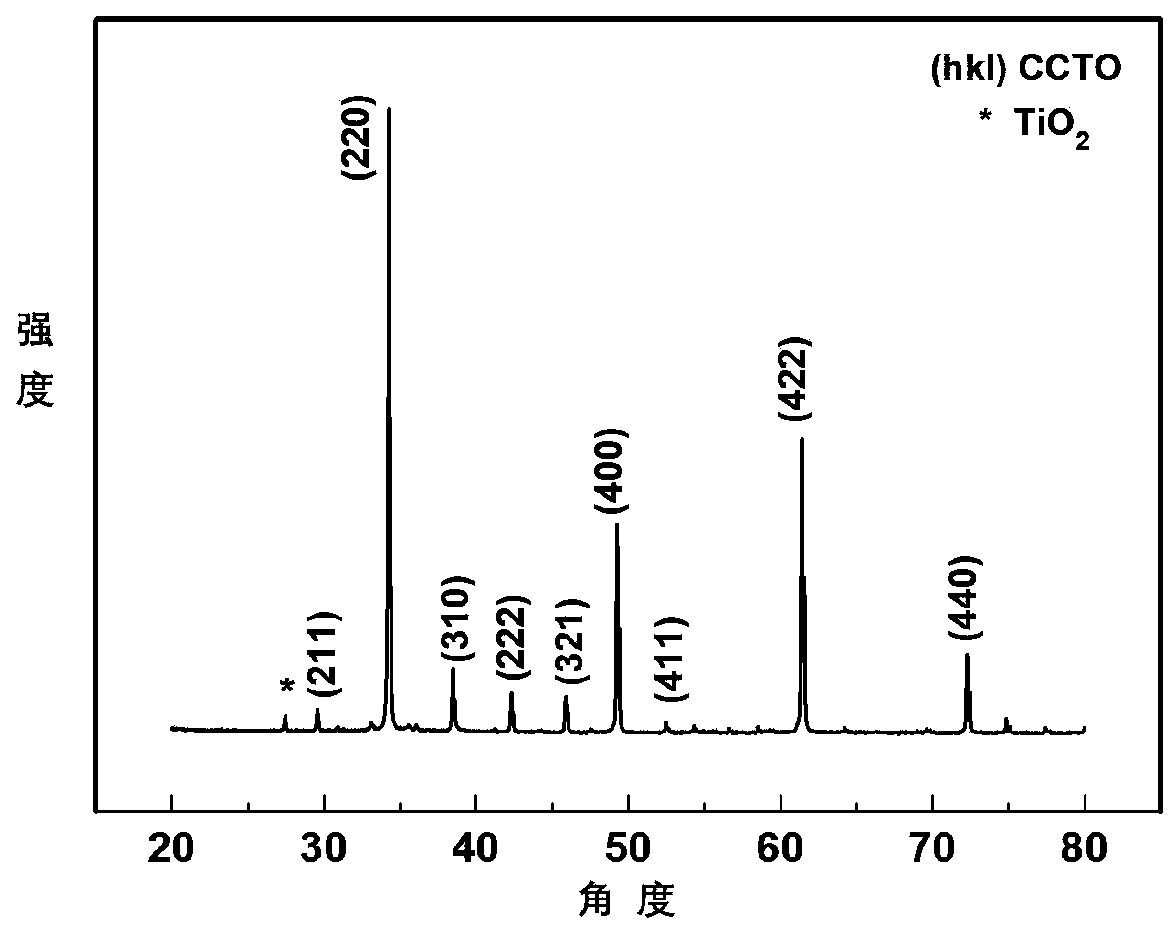

Giant-dielectric-constant low-loss CCTO-based ceramic material preparation method

A ceramic material and low-loss technology, which is applied in the preparation of low-loss CCTO-based ceramic materials and the field of giant dielectrics, can solve the problems of complex process and failure to improve the overall performance of CCTO materials, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

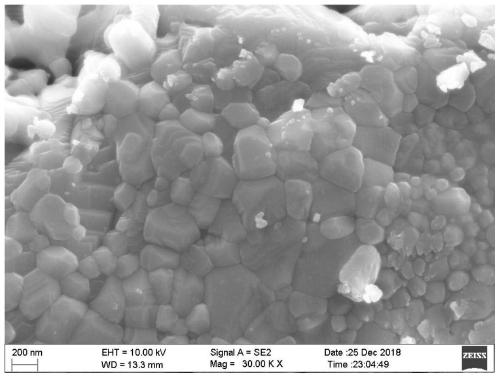

Embodiment 1

[0028] Using tetrabutyl titanate, copper nitrate, and calcium acetate as the precursor raw materials, with absolute ethanol and glacial acetic acid as the solvent, first weigh 0.04mol of tetrabutyl titanate, dissolve it in absolute ethanol, and stir with a glass rod Mix evenly, add glacial acetic acid, and continue stirring for 1 hour with a magnetic stirrer to prepare a precursor solution containing titanium ions, and weigh 0.03mol of Cu(NO 3 ) 2 ·3H 2 O, dissolved in absolute ethanol, stirred on a magnetic stirrer to a clear and transparent blue solution, and then this blue solution was added to the aforementioned precursor solution containing titanium ions to form a clear and transparent blue-green solution. To prepare a solution containing calcium ions, a certain amount of Ca(CH 3 COO) 2 ·H 2 O, be dissolved in 40ml deionized water to obtain a solution containing calcium ions. Slowly add this solution dropwise to the aforementioned blue-green solution containing titan...

Embodiment 2

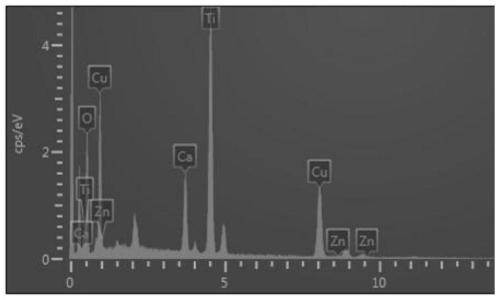

[0030] Using tetrabutyl titanate, copper nitrate, and calcium acetate as the precursor raw materials, with absolute ethanol and glacial acetic acid as the solvent, first weigh 0.04mol of tetrabutyl titanate, dissolve it in absolute ethanol, and stir with a glass rod Mix evenly, add glacial acetic acid, and continue stirring for 1 hour with a magnetic stirrer to prepare a precursor solution containing titanium ions, and weigh 0.02mol of Cu(NO3 ) 2 ·3H 2 O, dissolved in absolute ethanol, stirred on a magnetic stirrer to a clear and transparent blue solution, and then this blue solution was added to the aforementioned precursor solution containing titanium ions to form a clear and transparent blue-green solution, and weighed at the same time Dissolve 0.01mol of zinc acetate in 20ml of deionized water, stir evenly, add the aforementioned solution containing titanium ions and copper ions, similarly prepare a solution containing calcium ions according to the ratio, that is, weigh a ...

Embodiment 3

[0032] Using tetrabutyl titanate, copper nitrate, and calcium acetate as the precursor raw materials, with absolute ethanol and glacial acetic acid as the solvent, first weigh 0.04mol of tetrabutyl titanate, dissolve it in absolute ethanol, and stir with a glass rod Mix evenly, add glacial acetic acid, and continue to stir for 1 hour with a magnetic stirrer to prepare a precursor solution containing titanium ions, and weigh 0.03mol of Cu(NO 3 ) 2 ·3H 2 O, dissolved in absolute ethanol, stirred on a magnetic stirrer to a clear and transparent blue solution, and then this blue solution was added to the aforementioned precursor solution containing titanium ions to form a clear and transparent blue-green solution. To prepare a solution containing calcium ions, a certain amount of Ca(CH 3 COO) 2 ·H 2 O, be dissolved in 60ml deionized water to obtain a solution containing calcium ions. Slowly add this solution dropwise to the aforementioned blue-green solution containing titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com