Thick high-temperature-resistant steel structure anticorrosive paint and preparation process thereof

An anti-corrosion coating and high-temperature-resistant technology, applied in the field of coatings, can solve problems such as easy breeding of bacteria, achieve storage stability, strong physical and chemical properties, strong bonding performance, and the effect of protecting steel structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

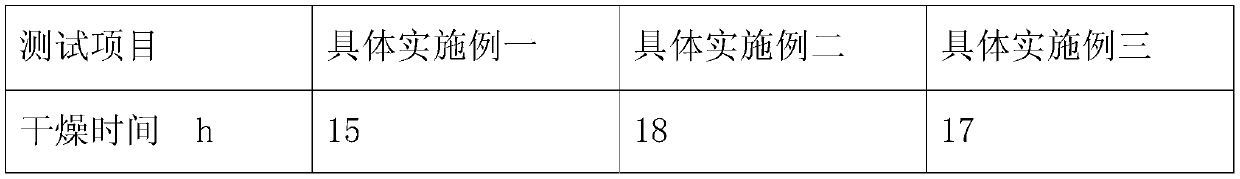

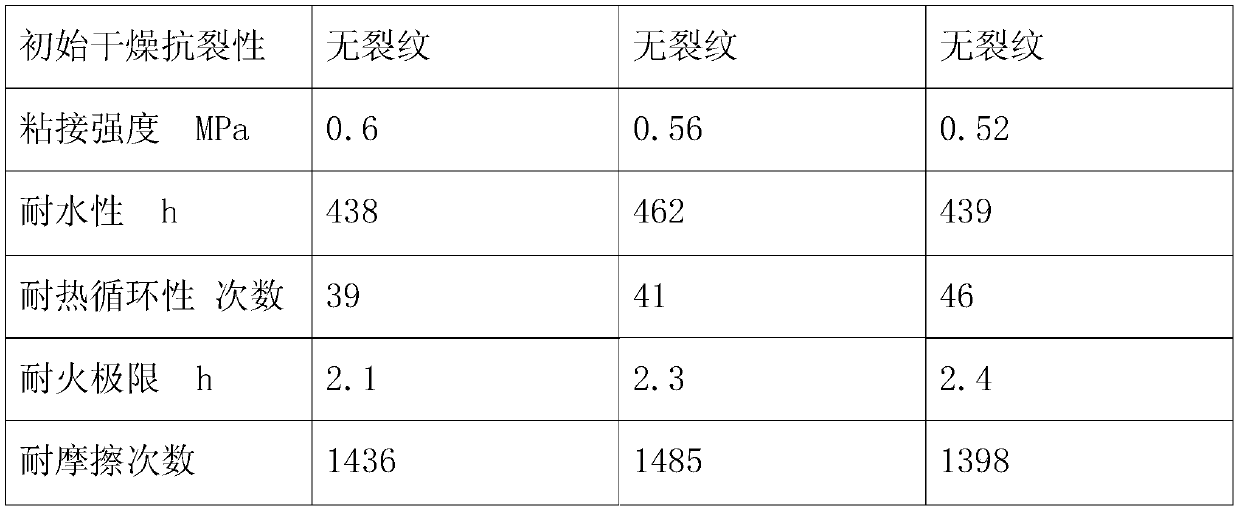

[0019] Specific embodiment one, a kind of thick high temperature resistant steel structure anticorrosion coating, it comprises the following components by weight percentage, organic pigment 1%, fireproof filler 5%, preservative 2%, color paste 0.2%, modified acrylic acid waterproof 2% emulsion, 5% epoxy resin, 0.4% thickener, 1% dispersant, 1% defoamer, 1% leveling agent, 2% film-forming aid and 79.4% water.

specific Embodiment approach 2

[0020] Specific embodiment two, a kind of thick high temperature resistant steel structure anticorrosion coating, it comprises the following components by weight percentage, organic pigment 2%, fireproof filler 7%, preservative 3%, color paste 0.6%, modified acrylic acid waterproof 3% emulsion, 6% epoxy resin, 0.6% thickener, 2% dispersant, 2% defoamer, 2% leveling agent, 3% film-forming aid and 68.8% water.

specific Embodiment approach 3

[0021] Specific embodiment three, a thick anti-corrosion paint for high temperature steel structure, which includes the following components by weight percentage, organic pigment 1.5%, fireproof filler 6%, preservative 2.5%, color paste 0.4%, modified acrylic acid waterproof Emulsion 2.5%, epoxy resin 5.5%, thickener 0.5%, dispersant 1.5%, defoamer 1.5%, leveling agent 1.5%, film-forming aid 2.5% and water 74.1%.

[0022] Further, the organic pigment is gamboge.

[0023] Further, the fireproof filler is expanded perlite.

[0024] Further, the film-forming aid is an alcohol fat twelve film-forming aid.

[0025] Further, the preservative is an isothiazolinone derivative.

[0026] A preparation process for a thick high temperature resistant steel structure anticorrosion coating, which comprises the following steps:

[0027] The first step, weighing, the following components by weight percentage, organic pigment 1-2%, fireproof filler 5-7%, preservative 2-3%, color paste 0.2-0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com