Moving coil type actuator for active suspension of engine

An active suspension and moving coil technology, which is applied to mechanical equipment, springs/shock absorbers, springs, etc., can solve problems such as low resonance frequency, large mass of the mover, and poor vibration reduction effect of active suspension, and achieves improved Response speed, light weight of mover, and simplified control algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The engine mount is an automotive powertrain used to reduce and control the transmission of engine vibration and play a supporting role. Active vibration reduction is a vibration reduction control technology that requires external energy. It realizes structural vibration reduction control by applying a control force that is opposite to the original vibration direction.

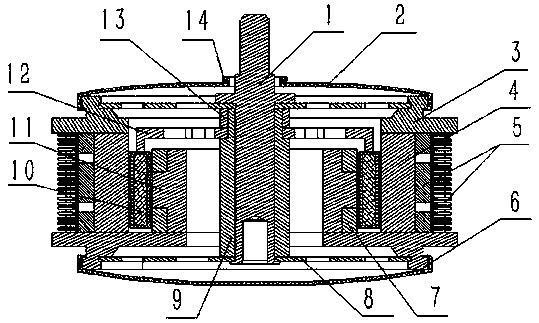

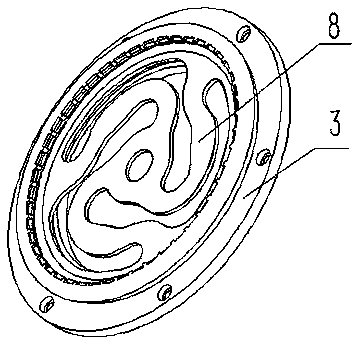

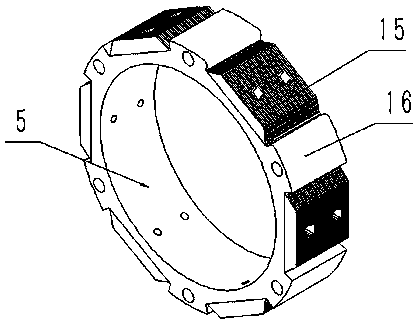

[0026] Please refer to Figure 1 to Figure 3 , a moving coil actuator for active suspension of an engine, comprising: a push rod 1, an upper protective cover 2, an end cover 3, an outer armature 4, a cooling device 5, a lower protective cover 6, a permanent magnet 7, a piece Spring 8, distance tube 9, coil 10, inner armature 11, coil support 12, fastening sleeve 13, snap ring 14, heat sink 15, casing 16. The upper end cover and the lower end cover are respectively connected to the top and bottom of the casing, the outer armature 4, the permanent magnet 7, the distance tube 9, the coil 10, the inner arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com