Processing method of octahedral lattice structure and derivative topological configuration lattice structure of octahedral lattice structure

A technology of lattice structure and processing method, applied in the direction of building components, etc., can solve the problems of inability to obtain scalable production, reduce the intrinsic mechanical properties of matrix materials, and inability to apply high-performance metals, etc., to achieve rapid and efficient continuous processing Effects of manufacturing, high energy absorption, and improvement of specific stiffness and specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

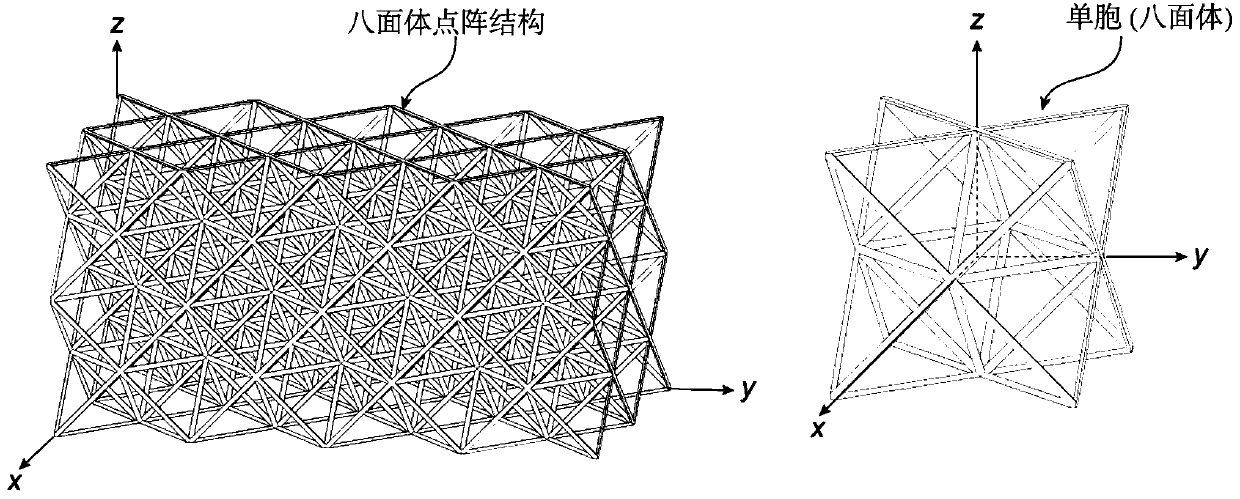

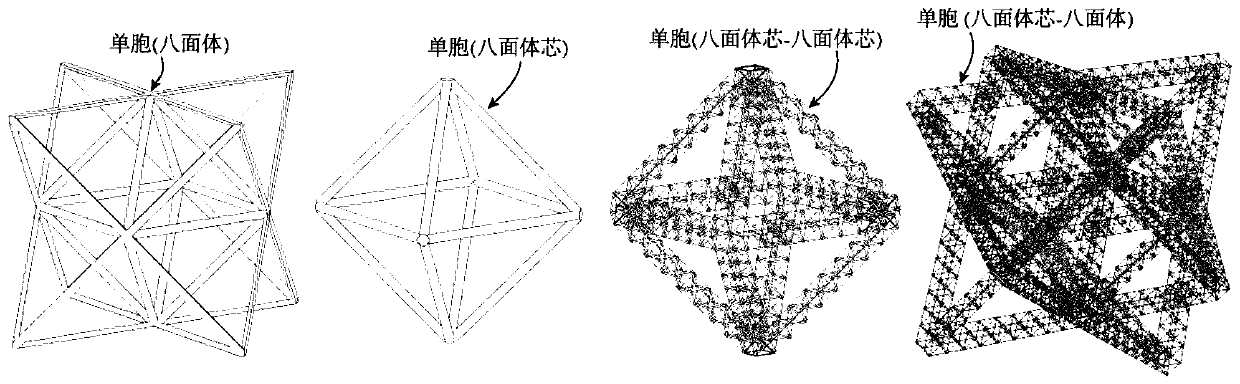

[0039] combined with Figure 1-15 , the processing method of octahedral lattice structure and derivative topology lattice structure thereof, comprises the following steps:

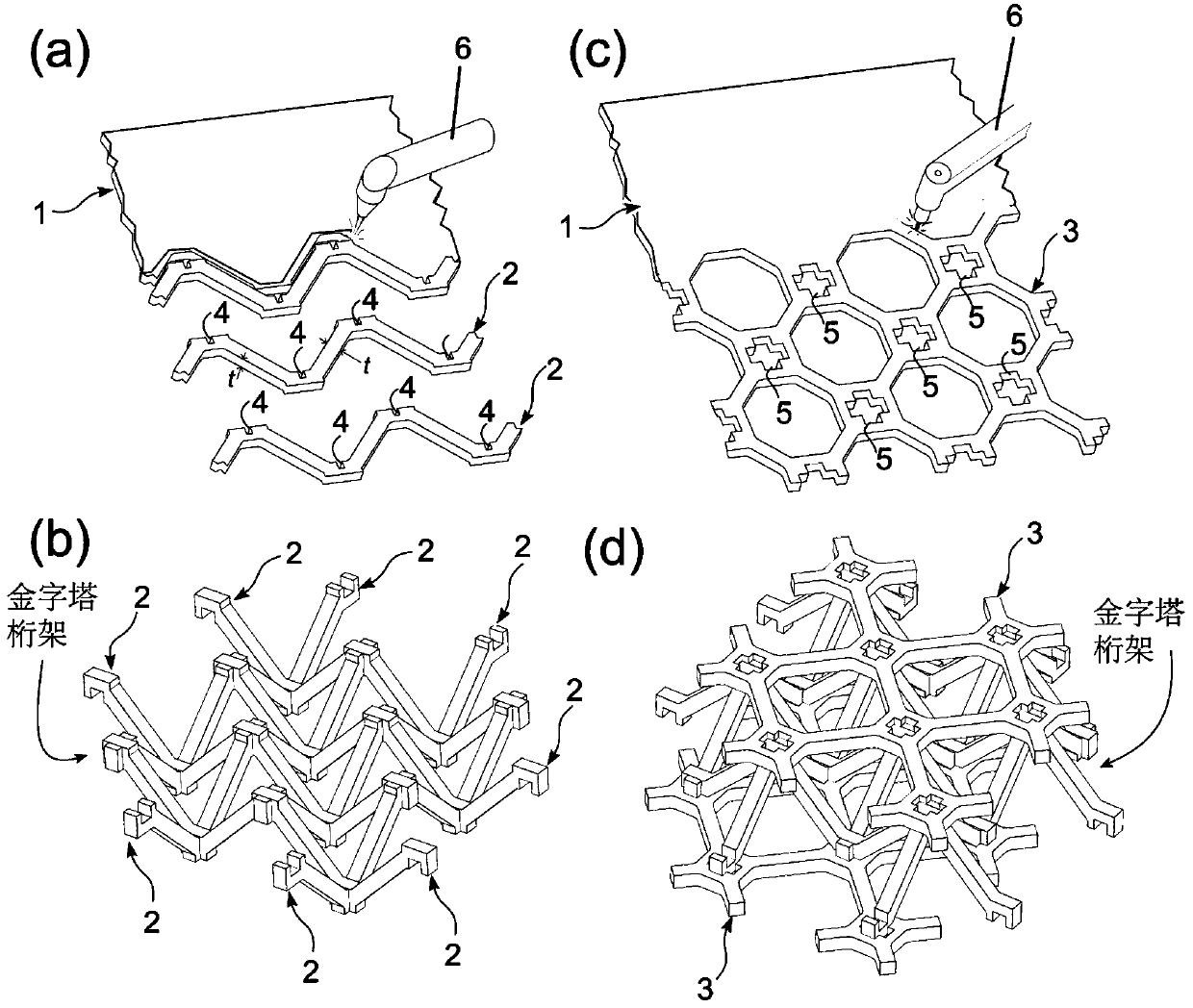

[0040] Such as image 3 As shown, the raw material is a plane plate 1, and the appropriate cutting method 6 is selected according to the specific material to cut and process the truss structural unit from the plane plate. For the sake of simplicity, we call image 3 Truss 2 shown in a is an out-of-plane truss, image 3 The truss 3 shown in c is an in-plane truss.

[0041] (1), making the in-plane truss 3 and the out-of-plane truss 2, the out-of-plane truss 2 has double hump-shaped slots 4 at the nodes, and the width of the slot is the thickness of the out-of-plane truss 2 (combined image 3 a), the out-of-plane trusses 2 are bayonet-fitted in an orthogonal arrangement to form a pyramid truss structure (combined image 3 b), the in-plane truss 3 has the same thickness as the out-of-plane truss 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com