Cuboid sodium-sodium-water integrated steam generator

A steam generator and cuboid technology are applied in the field of a cuboid sodium-sodium-water integrated steam generator, which can solve the problems of difficult installation, complicated operation and high-neutron radiation environment, and achieve lower manufacturing and installation requirements and process resistance. The effect of reducing and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

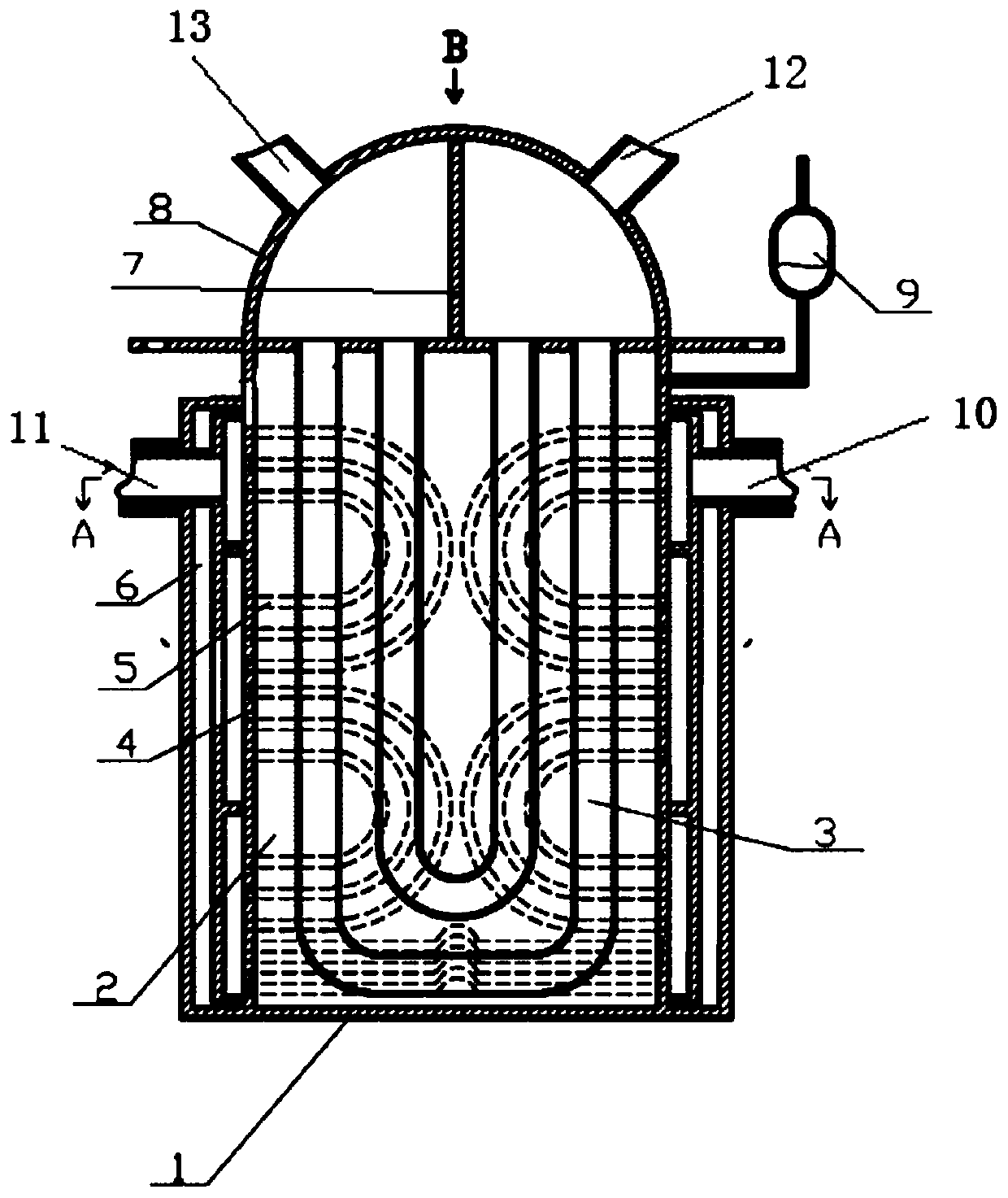

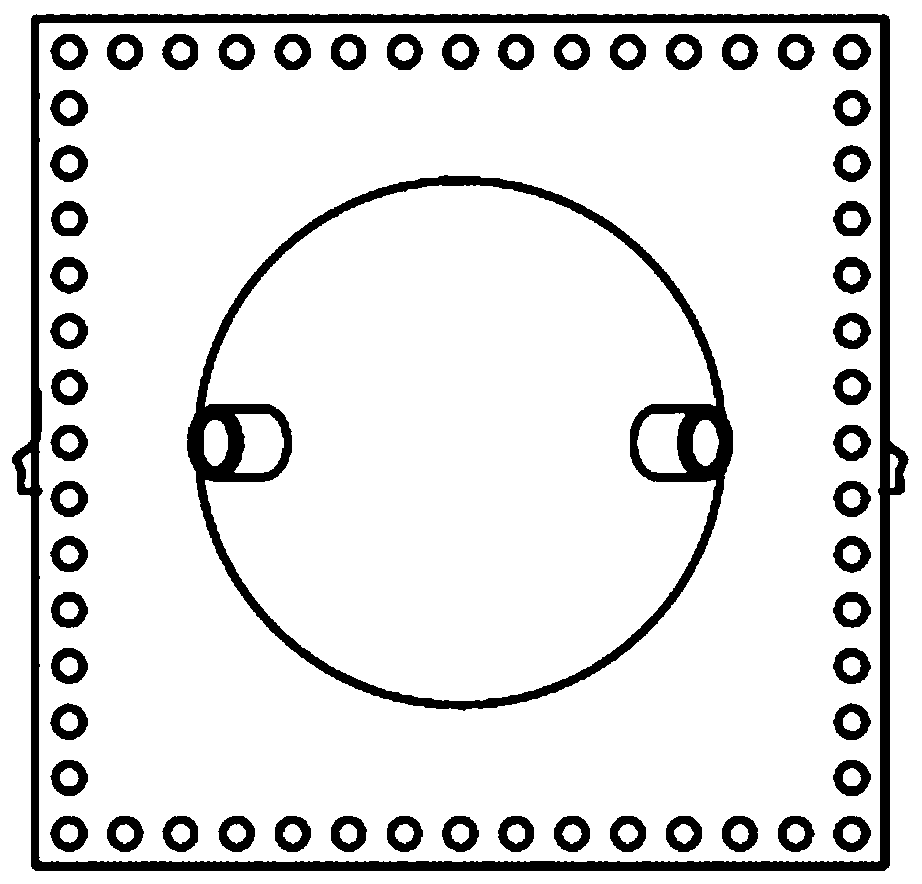

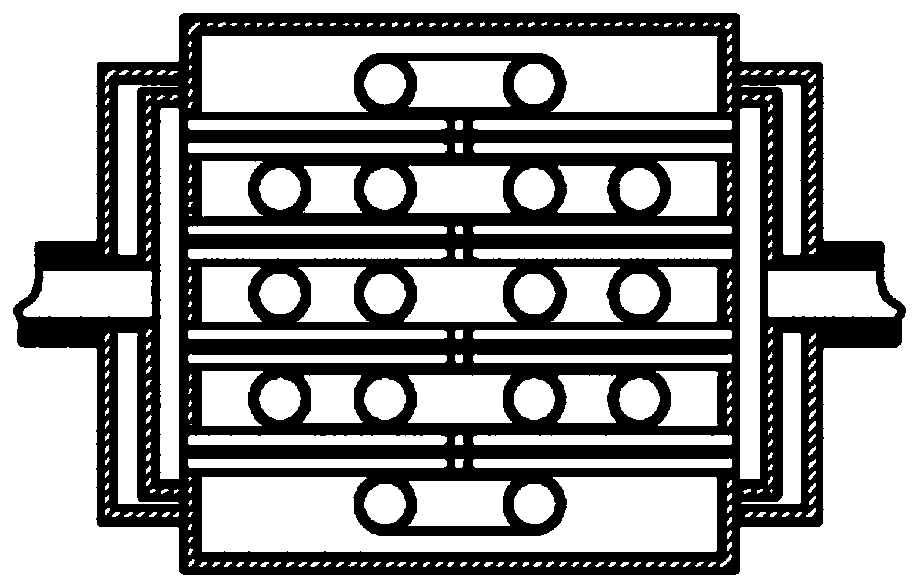

[0019] like Figure 1~3 As shown, a cuboid sodium-sodium-water integrated steam generator includes a cylinder body 4, an upper head 8, a sodium-water heat transfer tube 3 and a sodium-sodium heat transfer tube 5, wherein the cylinder body 4 is a cuboid shell body structure, the bottom plate 1 of the steam generator at the lower end forms a sealed integral structure with the side wall of the cylinder body, an upper tube plate is arranged at the upper end of the cylinder body 4, and several U-shaped sodium-water heat transfer tubes 3 are arranged on the cylinder body 4 inside, and the two ports on the upper end surface of the sodium-water heat transfer tube 3 are respectively welded and fixed on the left and right half planes of the upper tube sheet, and the partition plate 7 installed vertically in the center of the upper tube sheet an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com