Induction cooker coil panel capable of achieving circuit optimization and efficiently heating tray simultaneously

A technology of coil disk and induction cooker, which is applied to electric heating fuel, lighting and heating equipment, coil device, etc., can solve the problems of increasing copper loss, increasing the volume and weight of the coil disk of the induction cooker, and the failure of single-tube quasi-resonant converters to work. , to meet the impedance requirements and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

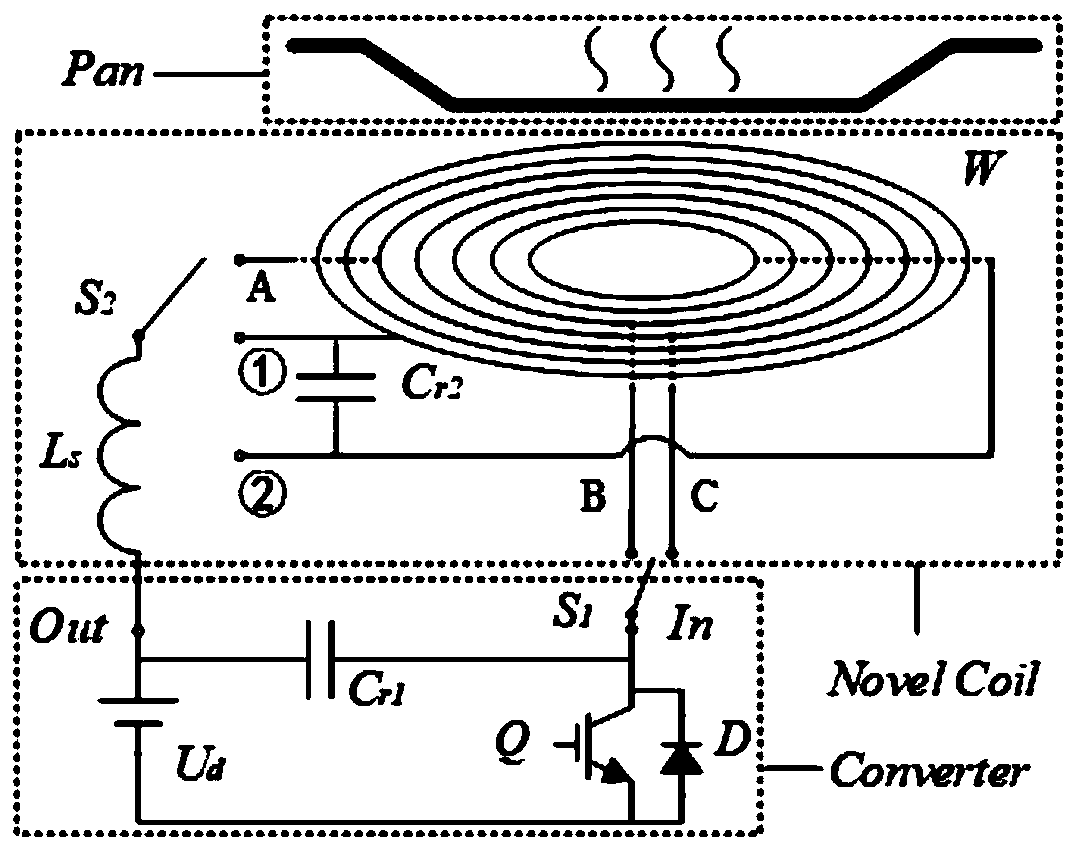

[0056] Figure 5 (a) is a schematic structural view of the first embodiment of the coil plate of an induction cooker that takes into account both circuit optimization and efficient heating of the hob according to the present invention, such as Figure 5 As shown in (a), in the first embodiment, the coil coil winding W is wound in a single-layer and whole section to reduce the volume and weight of the coil coil, and the tap A is drawn from the winding, and the coil coil winding W passes through ports ①, ② with additional capacitance C r2 The parallel connection forms a resonant unit. The winding between port ① and tap A is W 1 , the winding between port ② and tap A is W 2 . Additional inductance L s One end through the switch S 1 It is connected with port ① or port ②, that is, it is connected in series with the resonant unit to form an impedance transformation network, and then connected with the output end of the converter. where the additional inductance L s It can be...

Embodiment 2

[0070] Figure 5 (b) is a schematic structural view of the second embodiment of the coil plate of an induction cooker that takes into account circuit optimization and efficient heating of the plate of the present invention, such as Figure 5 As shown in (b), in the second embodiment, the coil coil W is wound in a double-layer and whole section, so as to increase the mutual inductance between each part of the winding and improve the heating efficiency of the coil coil W. Tap A, tap B, and tap C, taps A, B, and C can be set at any position in the double-layer winding, and the coil winding passes through ports ①, ② and the additional capacitor C r2 Parallel connections form a resonant unit. Where the winding between tap A and tap B is W 1 , the whole section of winding removes W 1 The rest is W 2 , the winding between tap A and tap C is W 3 , the whole section of winding removes W 3 The rest is W 4 . Additional inductance L s The tap A is connected in series with the res...

Embodiment 3

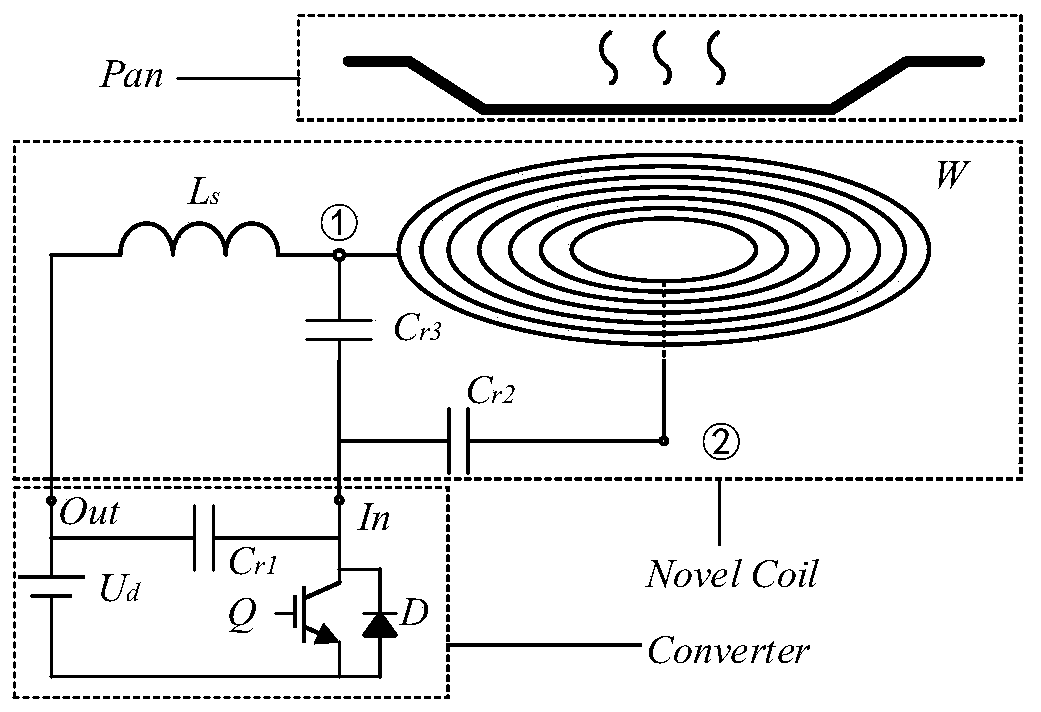

[0078] image 3It is a structural schematic diagram of the third embodiment of an induction cooker coil pan that takes into account circuit optimization and efficient heating of the hob, as shown in the present invention. image 3 As shown, in the third embodiment, the coil coil W is wound in a single-layer and whole section to reduce the volume and weight of the coil coil, and the coil coil W passes through the port ② and the additional capacitor C r2 connected in series to form a series branch, and then with the additional capacitance C r3 Connected in parallel to form a resonance unit. Additional inductance L s Port ① is connected in series with the resonant unit to form an impedance transformation network, and then connected to the output end of the converter. where the additional inductance L s It can be wound on the coil disk magnetic core together with the coil disk winding, and the magnetic core can be added to reduce the coupling with the pot to improve the utiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com