Settling tank of grain slag cooling water circulating system

A sedimentation tank and cooling water technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., to achieve the effects of increasing resource recycling, reducing mud content, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

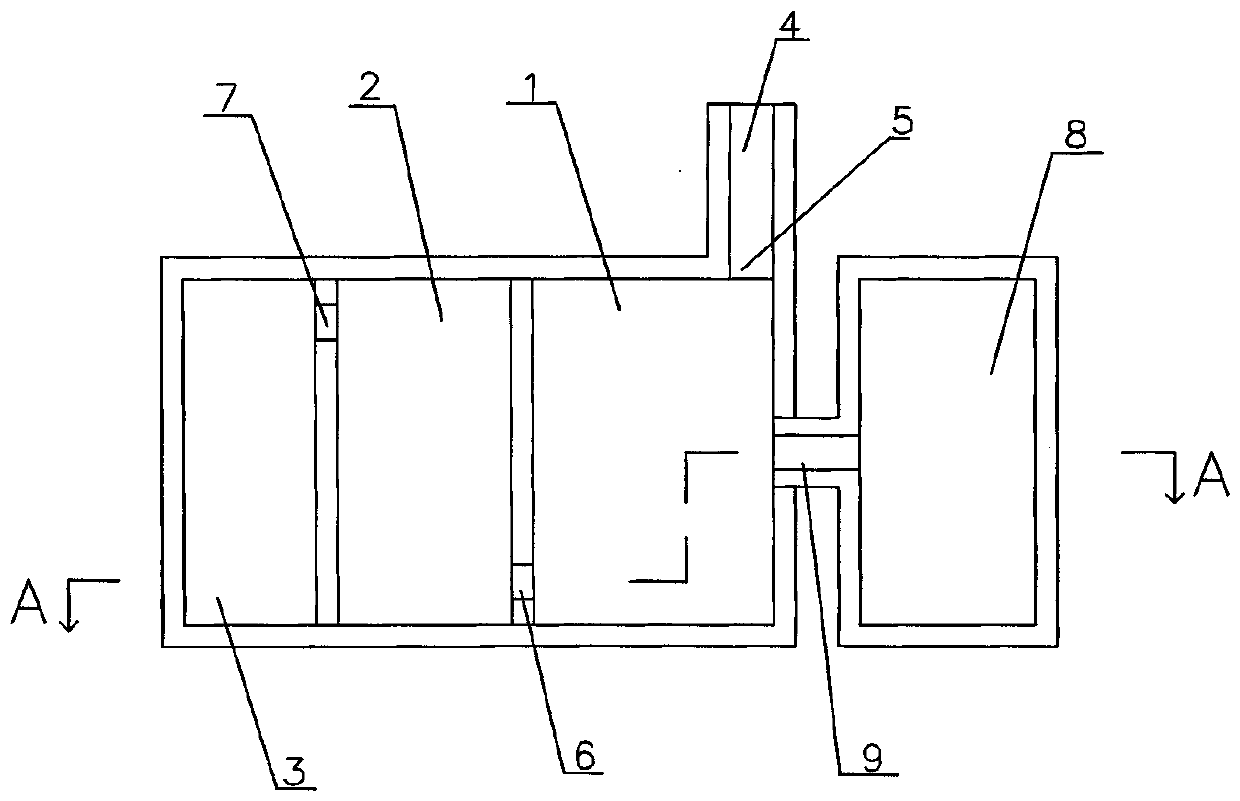

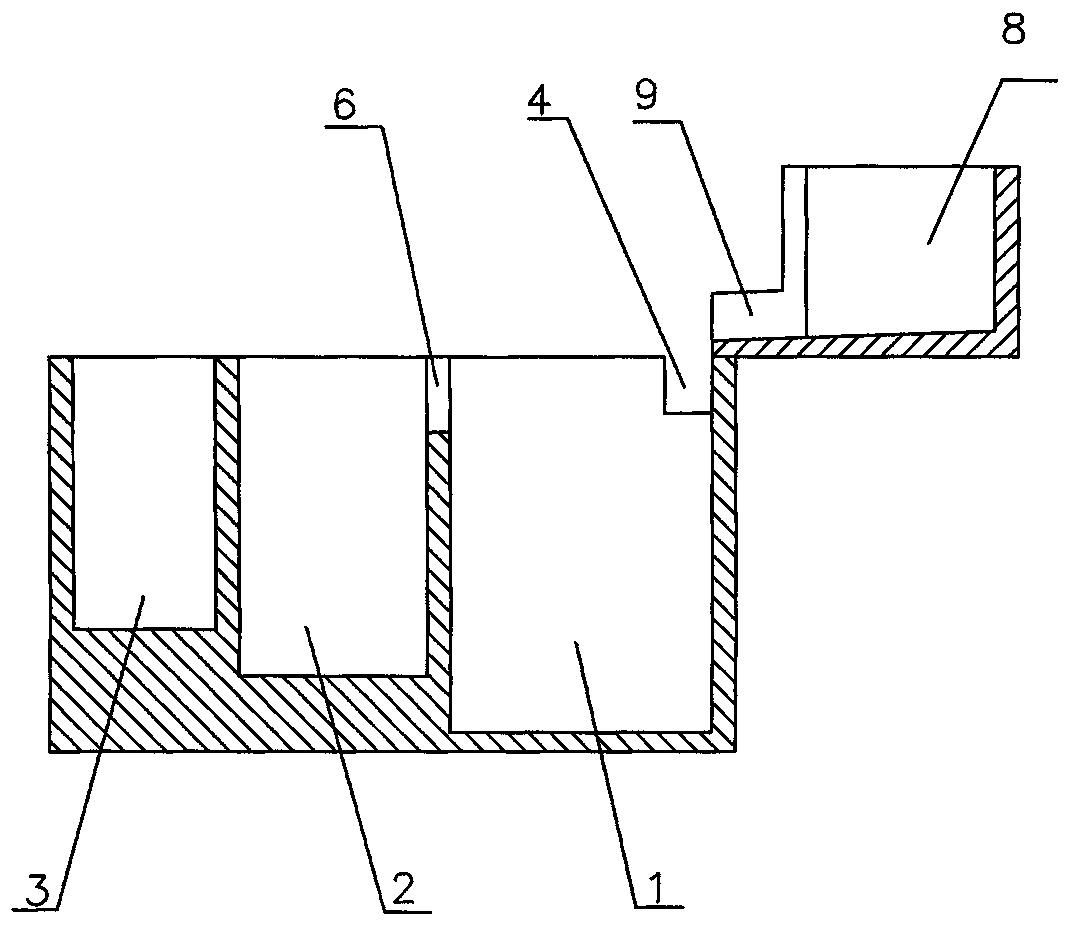

[0014] The sedimentation tank is divided into three levels according to the depth, the first-level sedimentation tank 1 is the deepest, and the third-level sedimentation tank 3 is the shallowest. The first-level sedimentation tank is 3.6 meters deep, the second-level sedimentation tank is 3.3 meters deep, and the third-level sedimentation tank is 3 meters deep. One end of the water channel 4 is connected to the slag tank, and the other end is connected to the primary sedimentation tank 1. There is a primary communication port 5 at the connection between the water channel 4 and the primary sedimentation tank 1, and there is a connection between the primary sedimentation tank 1 and the secondary sedimentation tank 2. The secondary communication port 6, the tertiary communication port 7 at the connection between the secondary sedimentation tank 2 and the tertiary sedimentation tank 3, the primary communication port 5 is at the upper left of the primary sedimentation tank 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com