Turnout notch monitoring system of a point switch

A monitoring system and switch machine technology, which is applied to closed-circuit television systems, measuring devices, instruments, etc., can solve the problems of imperfect information processing, single equipment status, and unintuitive information display, and achieve the effect of rich functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

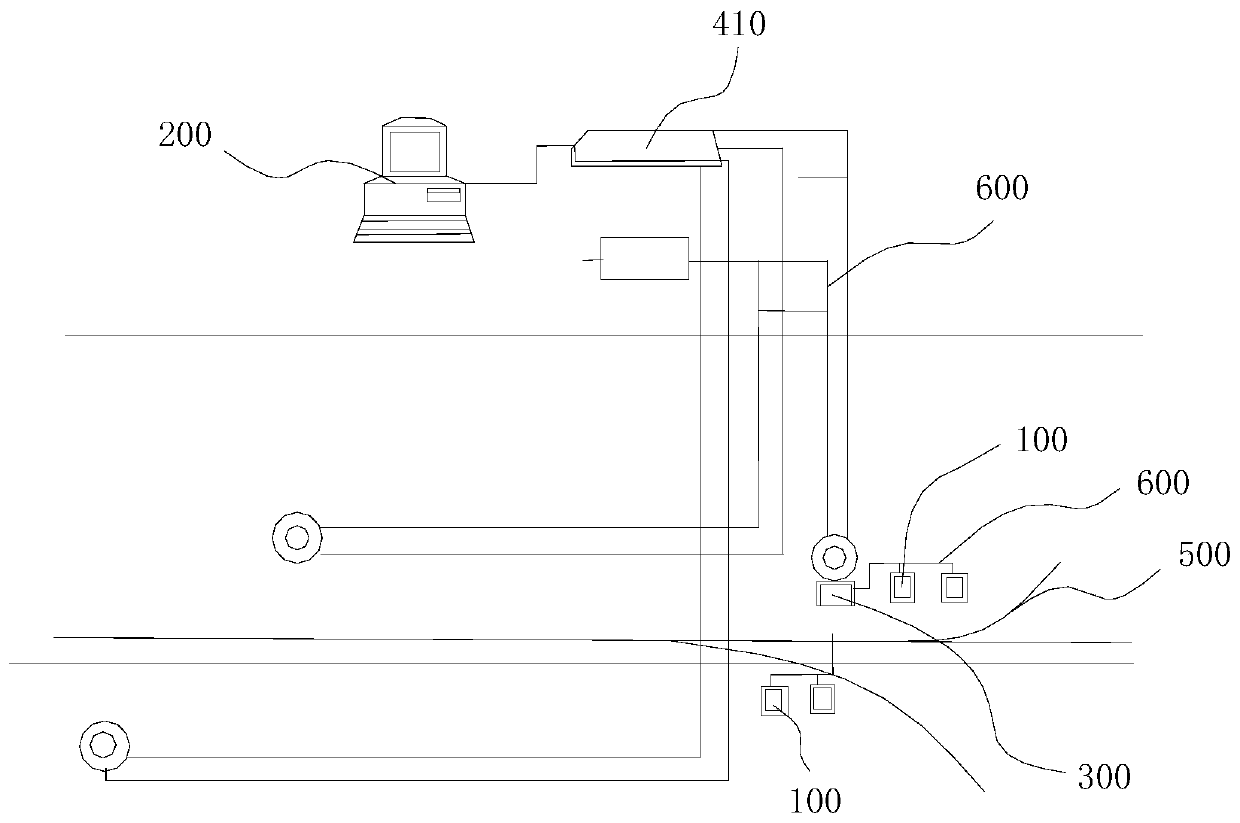

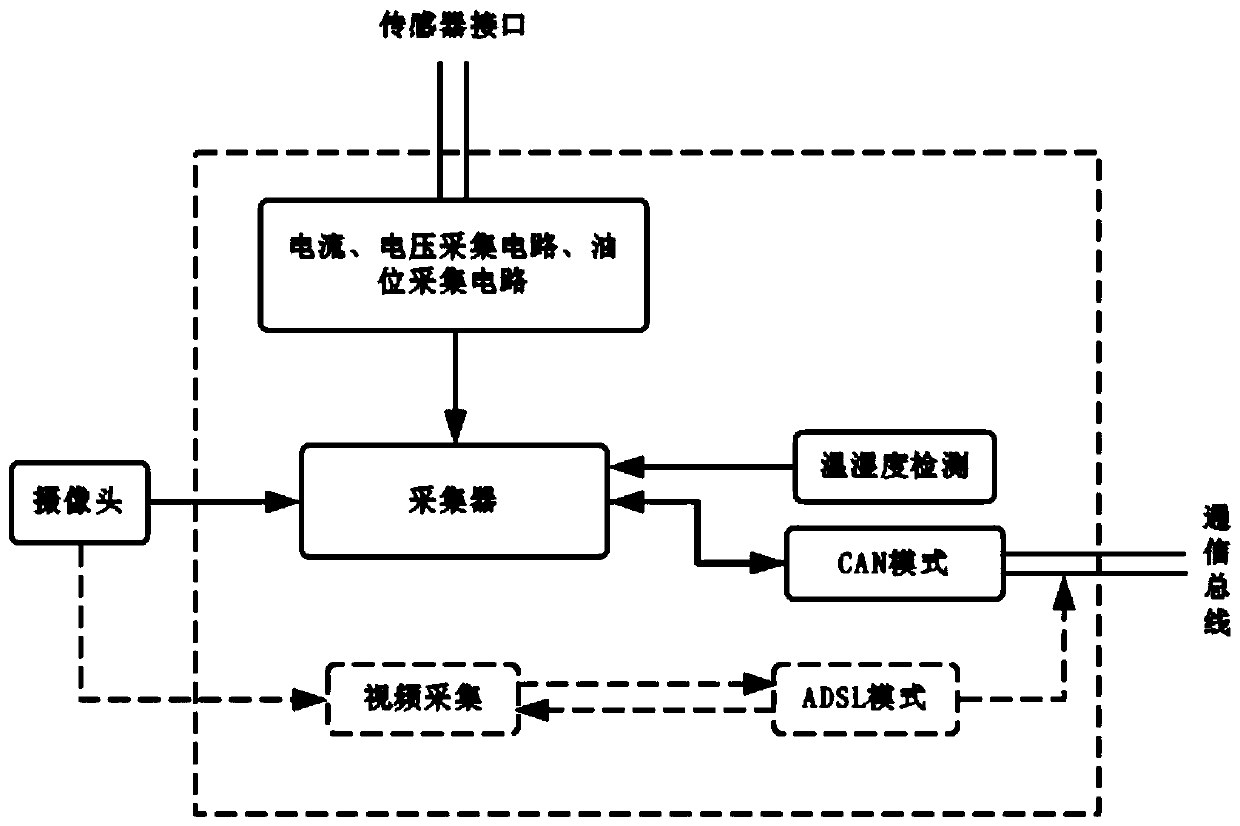

[0033] Such as Figure 1 to Figure 6 As shown, a point machine turnout gap monitoring system mainly includes an image collector 100, a communication server, a data transmitter, a communication converter 300, and a power box installed outdoors, and a monitoring industrial computer 200 installed indoors. Monitor the monitoring software on the industrial computer 200 .

[0034] The image collector 100 is installed at the traction point of each switch machine, and the indoor monitoring industrial computer 200 is installed in the mechanical room of each centralized station. In addition, according to the needs of the system, the oil pressure sensor in the electro-hydraulic switch machine can also be configured.

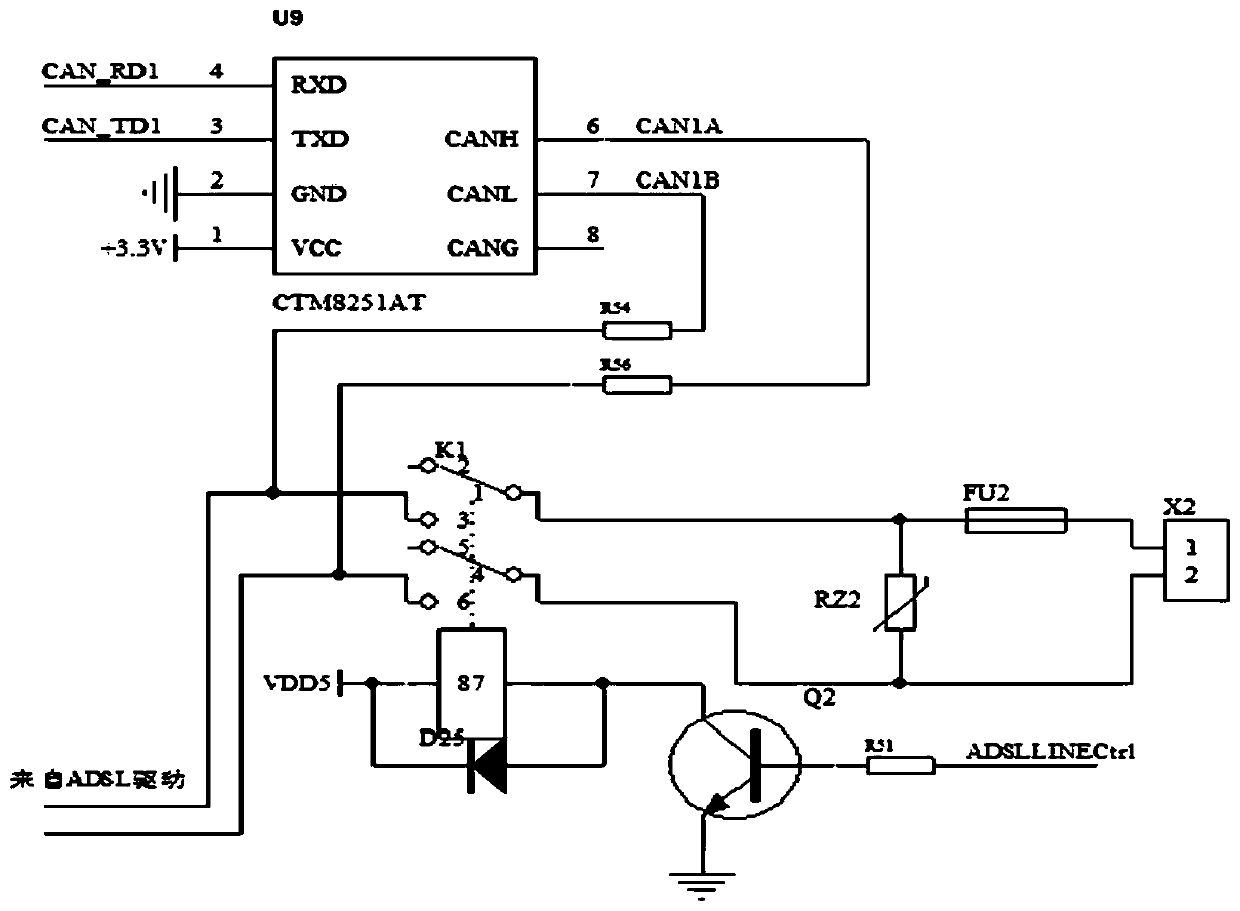

[0035] In the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com