Tanb alloy dental implant material and tanb alloy dental implant

A technology of implants and gold teeth, applied in dentistry, prostheses, dental implants, etc., can solve the problems of elastic modulus that cannot be satisfied at the same time, single implant material, high price, etc., to meet the needs of personalized customization , reduce environmental pollution, and overcome the effect of market monopoly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

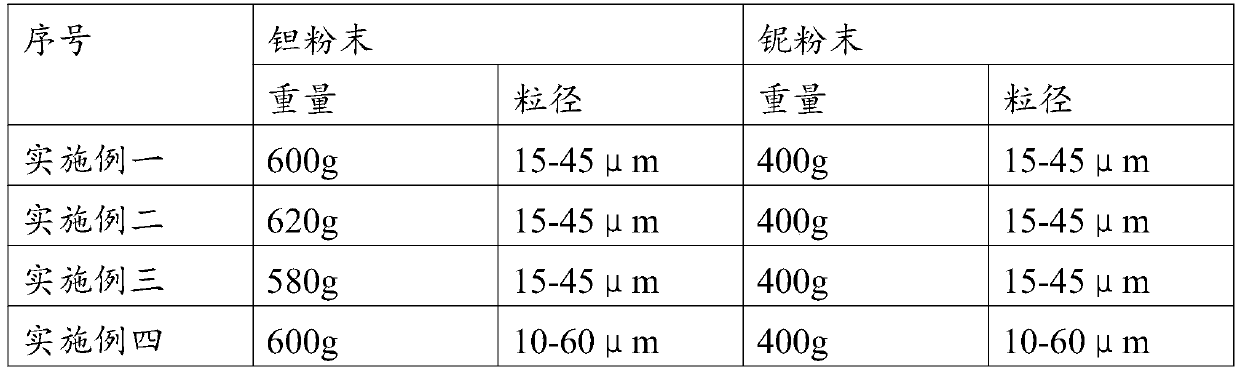

Embodiment 1

[0053] Step 1: Add tantalum powder with a diameter of 15-45 μm and niobium powder with a diameter of 15-45 μm into the mixer according to the ratio of Ta:Nb=600g:400g, and mix them thoroughly to form a tantalum-niobium alloy dental implant Material printing substrate powder;

[0054] Step 2: Reconstruct the dental implant model according to the pre-collected oral tooth defect information data;

[0055] Step 3: According to the dental implant model reconstructed by the computer, perform slices and analyze layer by layer to obtain slice layered cross-sectional profile data, and generate laser scanning melting paths of each layer of printing;

[0056] Step 4: Form the corresponding printing layer by pressing the printing substrate powder layer by layer on the lifting table, and scan the melting path according to the corresponding laser after each flat pressing of the printing substrate powder The digitally controlled laser selective scanning is performed on the printing layer, s...

Embodiment 2

[0061] Step 1: Add tantalum powder with a diameter of 15-45 μm and niobium powder with a diameter of 15-45 μm into the mixer according to the ratio of Ta:Nb=620g:400g, and mix them thoroughly to form a tantalum-niobium alloy dental implant Material printing substrate powder;

[0062] Step 2: Reconstruct the dental implant model according to the pre-collected oral tooth defect information data;

[0063] Step 3: According to the dental implant model reconstructed by the computer, perform tomographic analysis to obtain the contour data of the fault section, and generate the laser scanning melting path of each printing layer;

[0064] Step 4: Form the corresponding printing layer by pressing the printing substrate powder layer by layer on the lifting table, and scan the melting path according to the corresponding laser after each flat pressing of the printing substrate powder The digitally controlled laser selective scanning is performed on the printing layer, so that the printin...

Embodiment 3

[0070] Step 1: Add tantalum powder with a diameter of 15-45 μm and niobium powder with a diameter of 15-45 μm into the mixer according to the ratio of Ta:Nb=580g:400g, and mix them thoroughly to form a tantalum-niobium alloy dental implant Material printing substrate powder;

[0071] Step 2: Reconstruct the dental implant model according to the pre-collected oral tooth defect information data;

[0072] Step 3: According to the dental implant model reconstructed by the computer, perform slices and analyze layer by layer to obtain slice layered cross-sectional profile data, and generate laser scanning melting paths of each layer of printing;

[0073] Step 4: Form the corresponding printing layer by pressing the printing substrate powder layer by layer on the lifting table, and scan the melting path according to the corresponding laser after each flat pressing of the printing substrate powder The digitally controlled laser selective scanning is performed on the printing layer, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com