Three-dimensional spraying system and method

A three-dimensional, spraying unit technology, which is applied in liquid spraying devices, devices for coating liquid on surfaces, coatings, etc., can solve problems such as suppressing product output, prolonging spraying hours, and hidden dangers to workers' physical safety, so as to reduce air pollution and waste of resources, optimize the spraying operation process, and protect personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

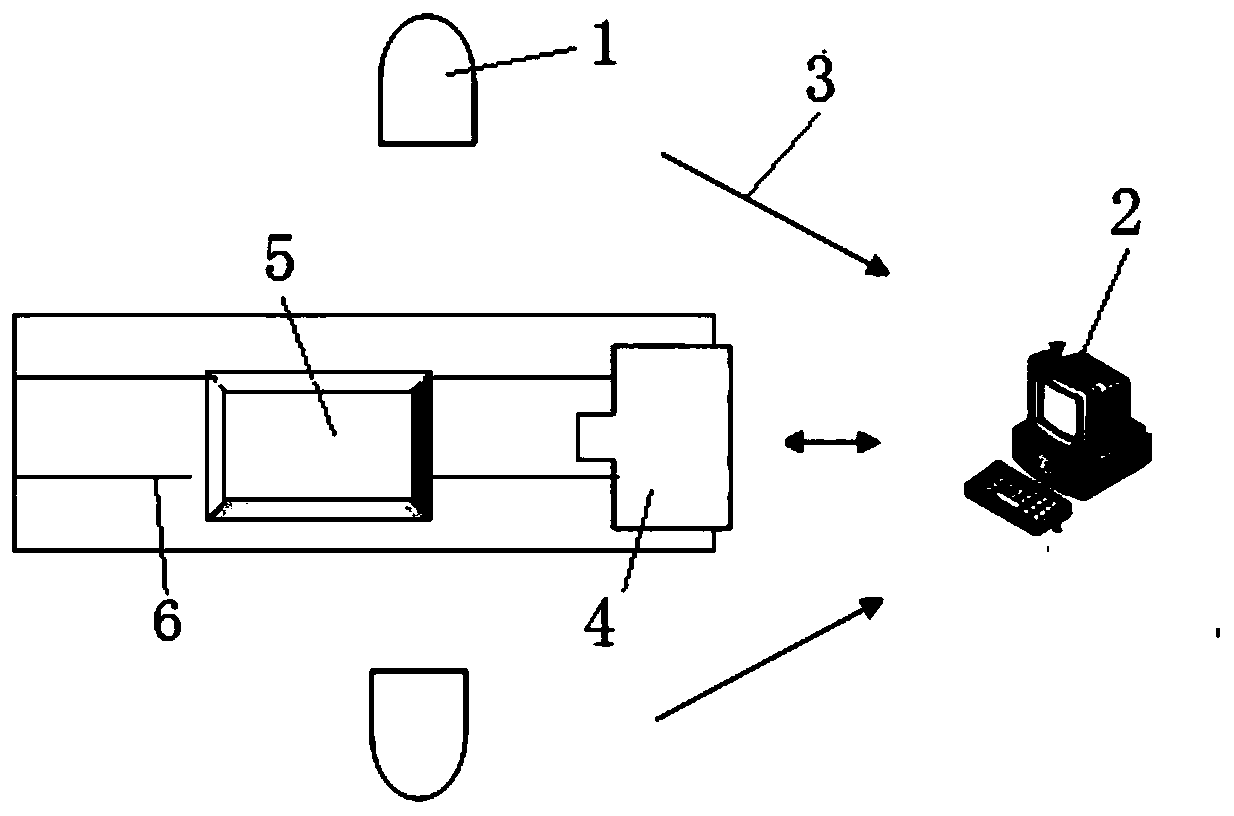

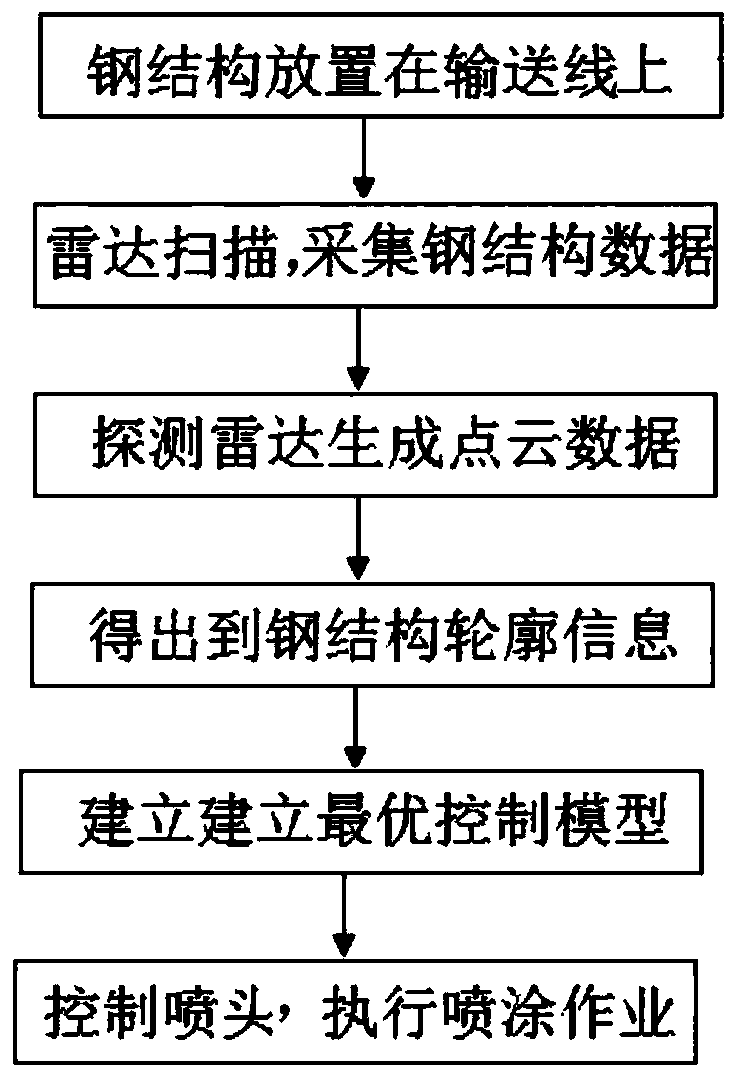

[0021] The three-dimensional spraying system of the present invention includes a detection unit, a data processing unit, a transmission unit and a spraying unit, and the detection unit and the spraying unit communicate with the data processing unit through the transmission unit. The detection unit performs three-dimensional scanning of the steel structure to be sprayed, collects the surface and position information of the steel structure, and generates point cloud data. The data processing unit processes the surface and position information of the steel structure collected by the detection unit, obtains the outline infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com