Laser cutting method and system for frosted glass

A laser cutting and frosted glass technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor surface scattering and cutting quality, achieve high processing efficiency, solve the effect of surface scattering and poor cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

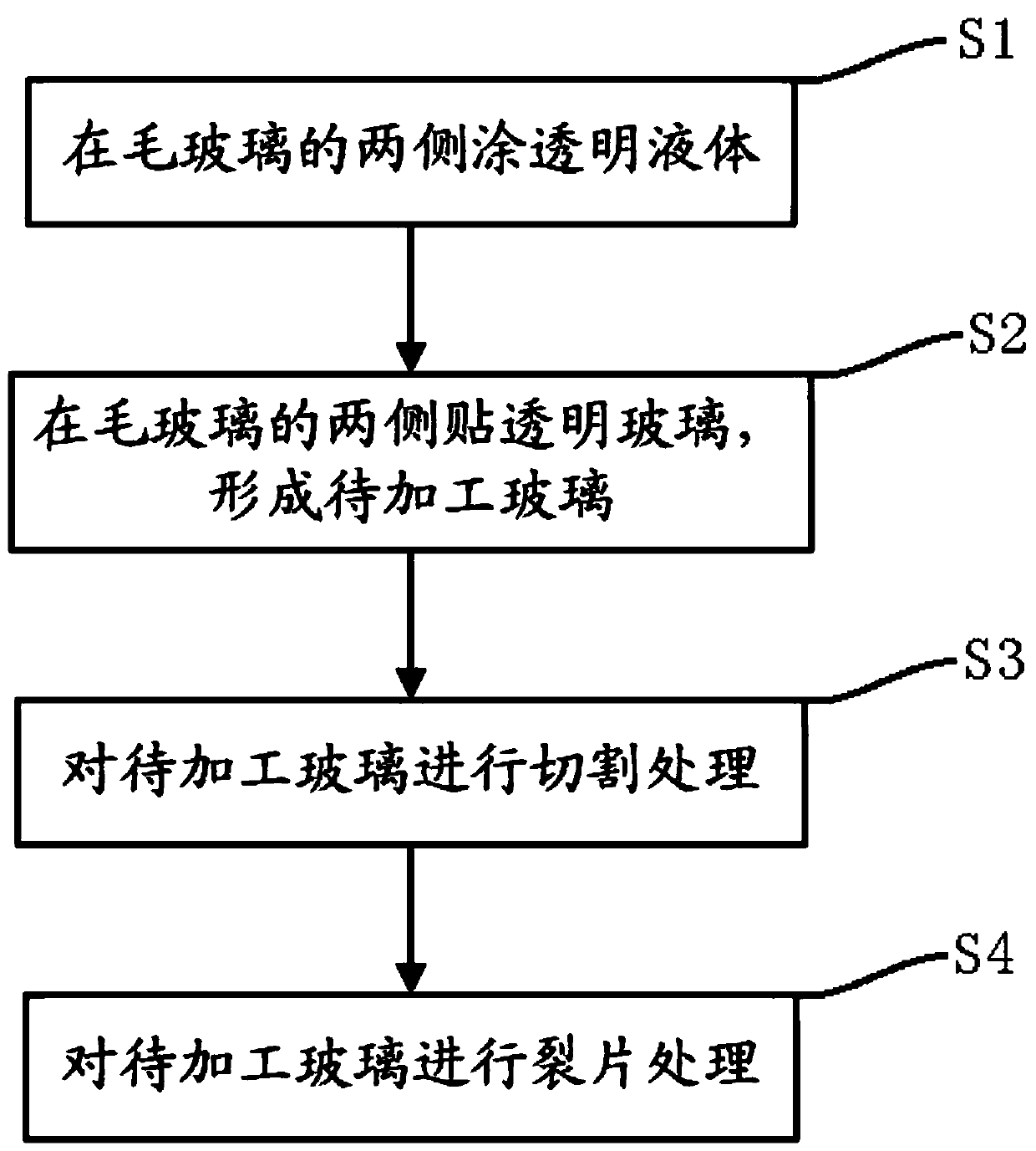

[0030] see figure 1 , a laser cutting method for frosted glass, comprising:

[0031] S1. Apply a transparent liquid on both sides of the frosted glass, and the refractive index of the transparent liquid is similar to that of the glass to be processed;

[0032] S2. Paste transparent glass on both sides of the frosted glass, press the frosted glass and the transparent glass, remove the air bubbles between the frosted glass and the transparent glass, and obtain the glass to be processed, which can make the frosted glass with poor light transmittance transparent and make the laser easier penetrate;

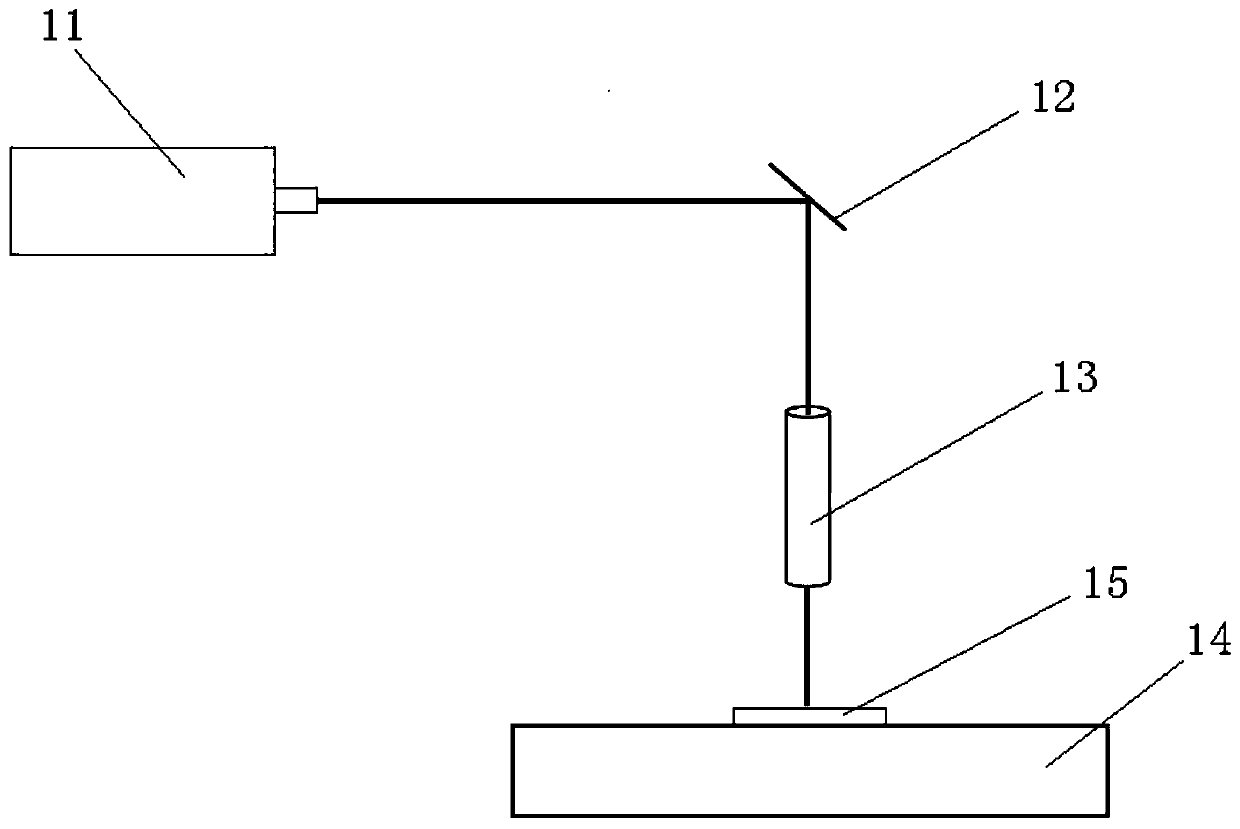

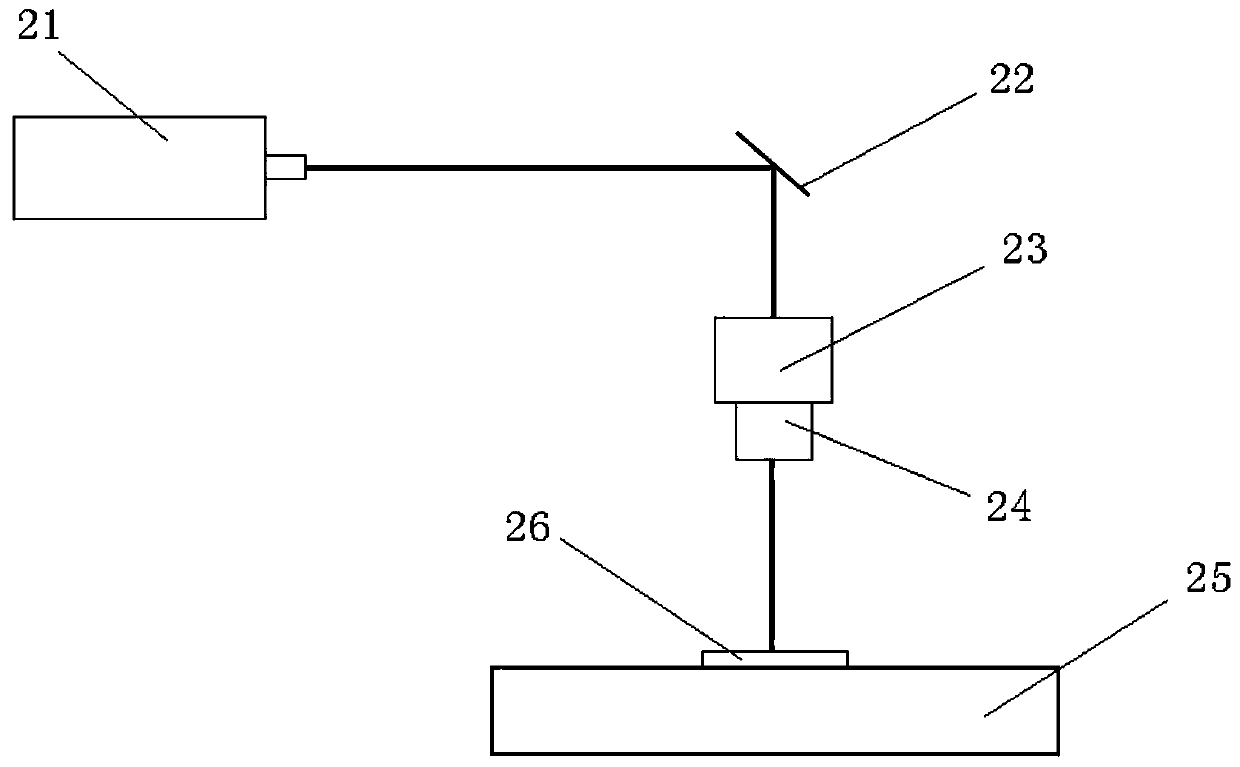

[0033] S3. Use a laser with a wavelength of 1030-1090nm and a pulse width of 5-15ps to cut the glass to be processed. Through the beam shaping effect of the cutting head, the Gaussian beam of the laser is shaped into a Bessel beam, and the Bessel beam is a focused beam. For a beam with a small spot and a long focal depth, the energy in the focal depth range is basically the same. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com