Method for connecting copper-silver alloy by high-temperature alloy ring-shaped member

A high-temperature alloy, copper-silver alloy technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of peeling of the connecting layer, high porosity of the connecting layer, and falling blocks, etc., to enhance the connection strength, avoid peeling, The effect of a reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

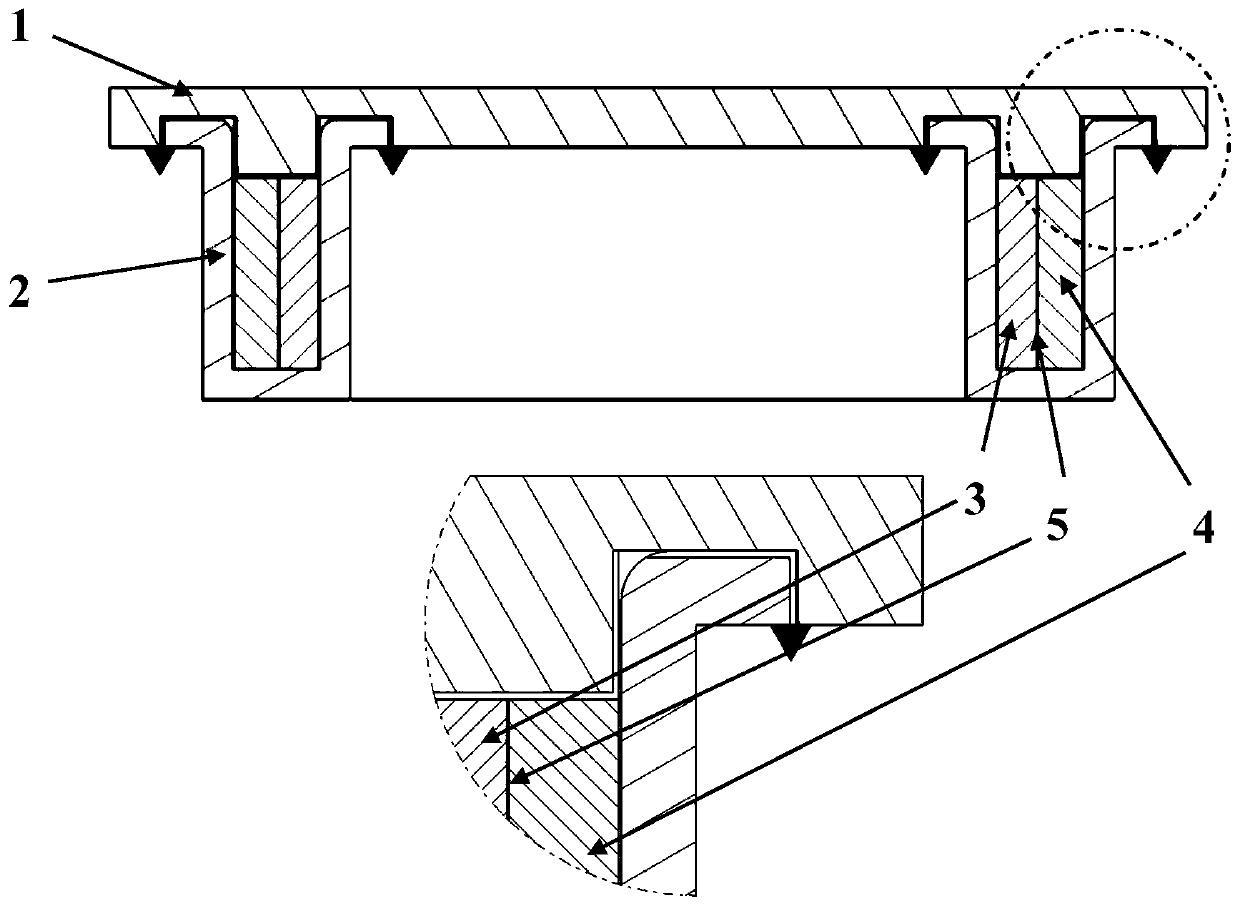

[0021] The method for connecting the copper-silver alloy with the high-temperature alloy ring provided by the present invention will be described in detail below with reference to the accompanying drawings and specific examples.

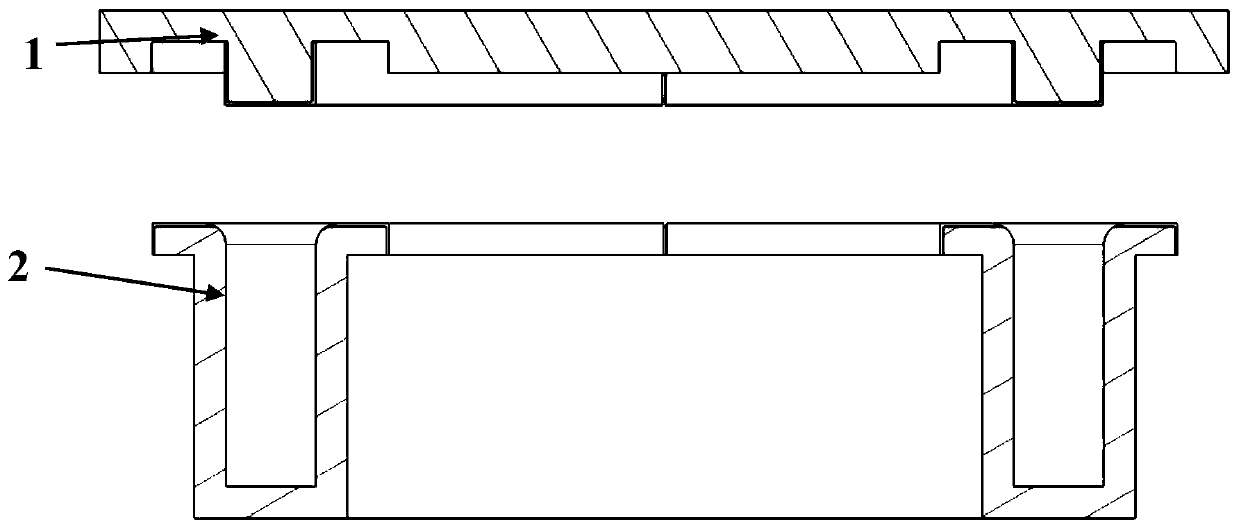

[0022] Such as figure 1 — Figure 4 As shown, the method for connecting the copper-silver alloy with the high-temperature alloy ring piece provided by the present invention comprises the following steps carried out in order:

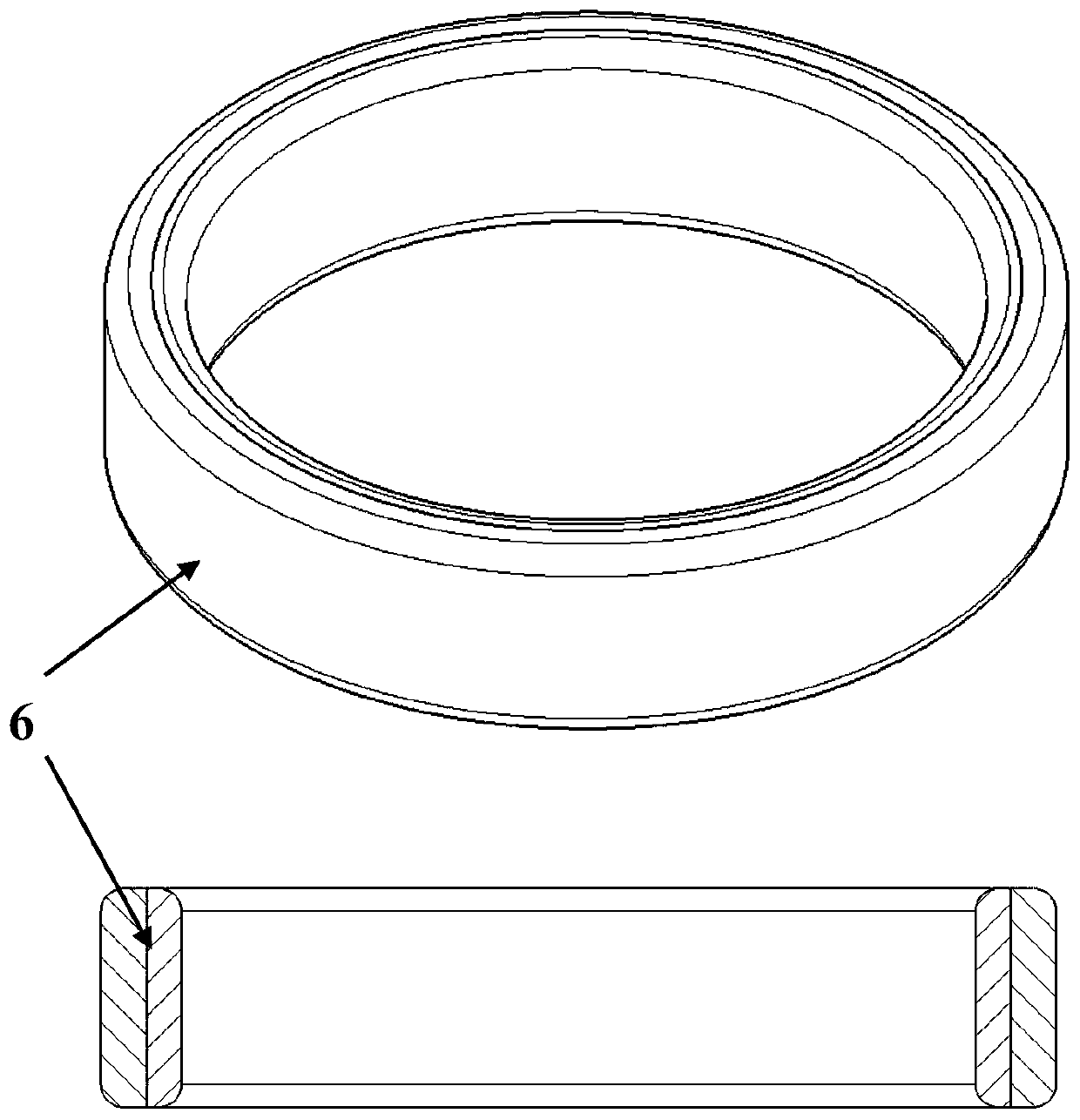

[0023] 1) According to the structural features of the final connecting piece 6, a superalloy ring piece 3 and a copper-silver alloy ring piece 4 are prepared. The material of the superalloy ring 3 can be nickel-based superalloys such as GH4169 and GH600 and iron-based superalloys such as GH2909, and the ratio of copper to silver in the copper-silver alloy material can be changed. In order to ensure the dimensional accuracy of the connecting parts, the connection position of the high-temperature alloy ring part 3 is processed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com