Reverse Osmosis System Applied to Industrial Concentrated Salt Sewage

A reverse osmosis and reverse osmosis membrane technology, applied in the field of reverse osmosis systems, can solve the problems of low hydrothermal stability of organic membranes, low salt retention rate and flux, easy blockage of reverse osmosis devices, etc. The effect of reducing and pressurizing equipment, preventing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

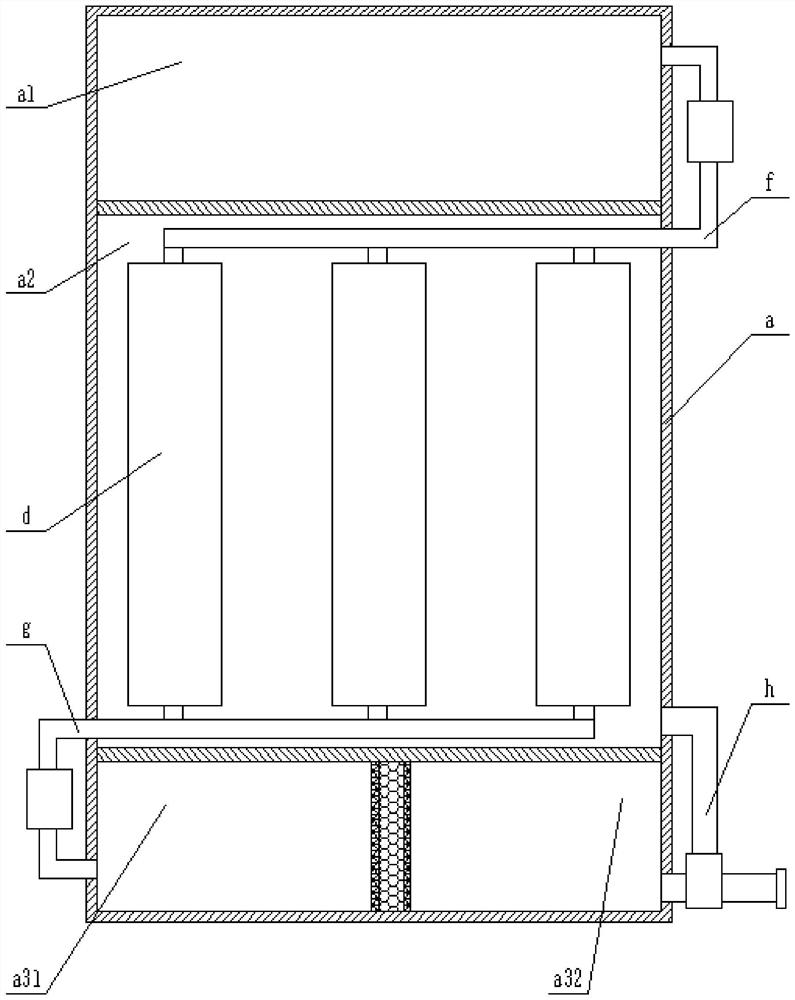

[0025] Embodiment 1 is applied to the reverse osmosis system I of industrial concentrated salt sewage

[0026] like Figure 1-3 As shown, a reverse osmosis system applied to industrial concentrated salty sewage includes a tank a, and two horizontal partitions are arranged in the tank a, and the two horizontal partitions separate the tank a It is the raw water chamber a1, the primary reverse osmosis chamber a2 and the secondary reverse osmosis chamber. A reverse osmosis device d, said secondary reverse osmosis chamber is provided with reverse osmosis membrane I, said reverse osmosis membrane I separates said secondary reverse osmosis chamber into a second permeation zone a31 and a second clean liquid zone a32;

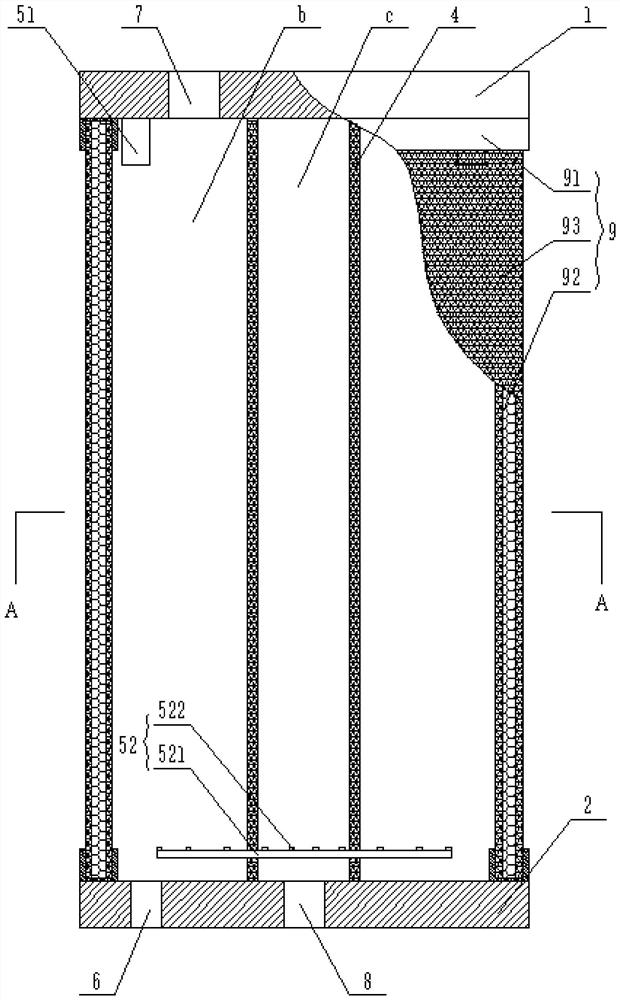

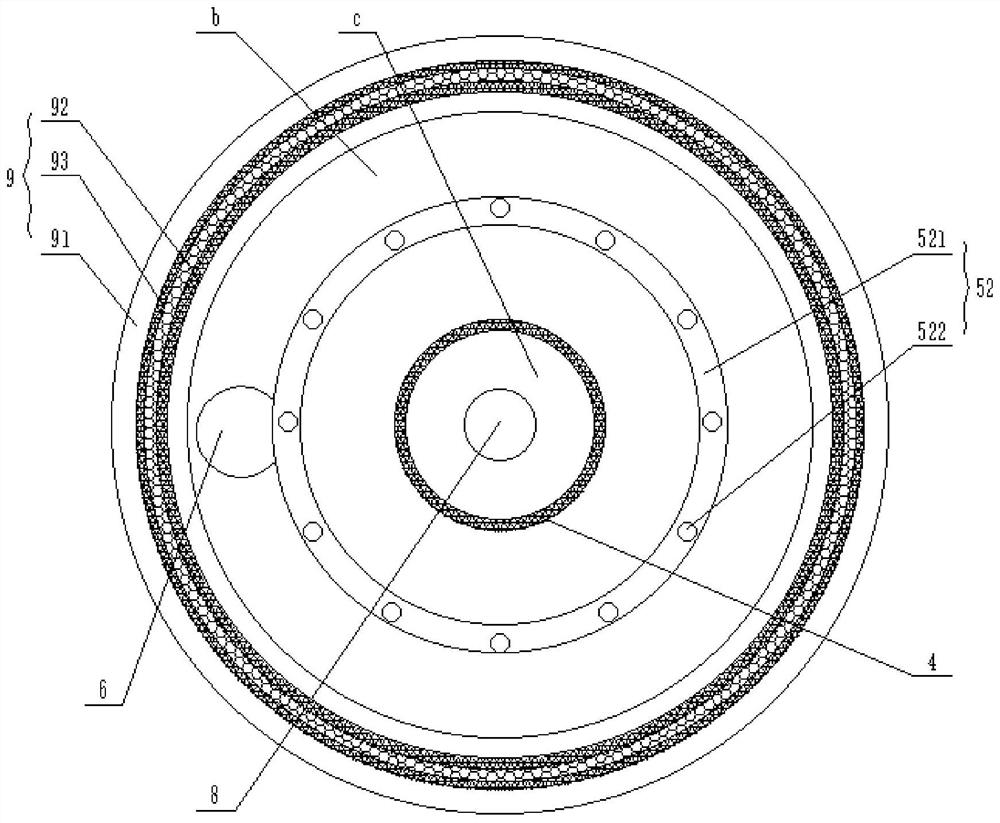

[0027] figure 2 and image 3As can be seen from above, the reverse osmosis device d includes an upper mounting base 1 and a lower mounting base 2 facing each other, and a reverse osmosis membrane I is arranged between the upper mounting base 1 and the lower mounting...

Embodiment 2

[0038] Embodiment 2 is applied to the reverse osmosis system II of industrial concentrated salt sewage

[0039] like Figure 1-3 As shown, a reverse osmosis system applied to industrial concentrated salty sewage includes a tank a, and two horizontal partitions are arranged in the tank a, and the two horizontal partitions separate the tank a It is the raw water chamber a1, the primary reverse osmosis chamber a2 and the secondary reverse osmosis chamber. A reverse osmosis device d, said secondary reverse osmosis chamber is provided with reverse osmosis membrane II, said reverse osmosis membrane II separates said secondary reverse osmosis chamber into a second permeation zone a31 and a second clean liquid zone a32;

[0040] figure 2 and image 3 As can be seen from above, the reverse osmosis device d includes an upper mounting base 1 and a lower mounting base 2 facing each other, and a reverse osmosis membrane II is arranged between the upper mounting base 1 and the lower mou...

Embodiment 3

[0051] Embodiment 3 is applied to the reverse osmosis system II of industrial concentrated salt sewage

[0052] like Figure 1-3 As shown, a reverse osmosis system applied to industrial concentrated salty sewage includes a tank a, and two horizontal partitions are arranged in the tank a, and the two horizontal partitions separate the tank a It is the raw water chamber a1, the primary reverse osmosis chamber a2 and the secondary reverse osmosis chamber. A reverse osmosis device d, said secondary reverse osmosis chamber is provided with reverse osmosis membrane III, and said reverse osmosis membrane III separates said secondary reverse osmosis chamber into a second permeation zone a31 and a second clean liquid zone a32;

[0053] figure 2 and image 3 As can be seen from above, the reverse osmosis device d includes an upper mounting base 1 and a lower mounting base 2 facing each other, and a reverse osmosis membrane III is arranged between the upper mounting base 1 and the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com