Method for rapidly preparing high-quality acrylamide gel film

An acrylamide gel film and acrylamide technology are applied in the field of rapidly preparing high-quality acrylamide gel films, and can solve the problems of low efficiency, complicated operation, long film-forming time, etc., so as to improve the film-forming quality and shorten the film-forming time. time, the effect of suitable promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

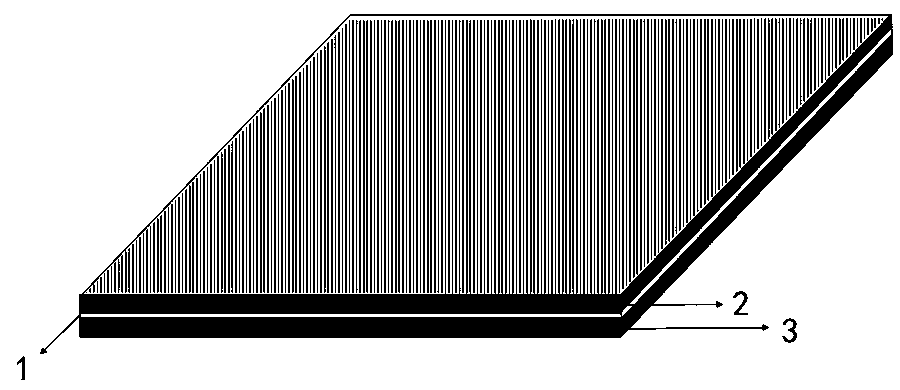

Image

Examples

Embodiment 1

[0029] The preparation method of high-quality acrylamide gel membrane provided by the present invention comprises the steps:

[0030] (1) Use a camera to wipe the glassware and two pieces of float glass with absorbent cotton dipped in acetone and absolute ethanol in sequence, and wipe off the small particles such as dust attached to the surface of the glassware and float glass, and initially remove the dust on the surface. Then put the glassware and two pieces of float glass in acetone and use ultrasonic cleaning for 10 minutes, then put them in alcohol and use ultrasonic cleaning for 10 minutes, then take them out with the camera and put them in deionized water and use ultrasonic cleaning for 5 minutes Minutes, use N after taking out 2 blow dry.

[0031] (2) Preparation of acrylamide prepolymerization solution:

[0032] Take 1ml of polyethylene glycol diacrylate (average molecular weight 600) into the glassware treated in step (1), add 0.15g of N-isopropylacrylamide (NIPAM,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com