Tea wine composition, preparation method and application thereof

A composition and tea technology, applied in the field of tea derivative products, can solve the problems of poor market acceptance and single taste of tea and tobacco, and achieve the effect of high market acceptance, good taste and strong fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

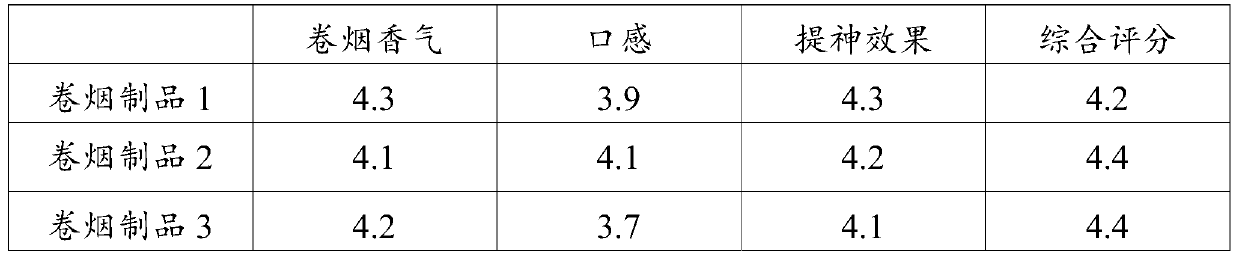

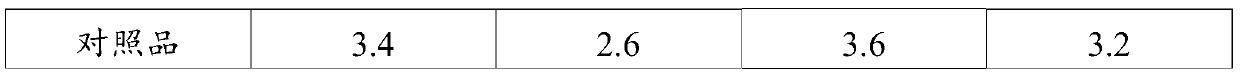

Examples

Embodiment 1

[0032] This embodiment is a specific embodiment for preparing the composition product 1.

[0033] The destemmed tea leaves were dried at 80° C. for 60 minutes to obtain the first product 1 with a water content reduced by 30%.

[0034] The first product 1 was dried at 90° C. for 65 minutes to obtain a second product 1 with a water content reduced by 20%.

[0035] The water content of the second product 1 is reduced by 10% after being dried at 80°C for 50 minutes, and after standing to room temperature, the tea extract 1 is sprayed on the surface, cut into filaments with a width of 0.5-2.3 mm, and the third product 1 is obtained; Among them, the spraying amount of the tea extract 1 is 4ml / Kg of the third product 1, and the preparation method of the tea extract 1 is: 100g of fresh tea leaves are crushed to 25-35 mesh, dissolved in 1Kg of water, concentrated at 90°C for 120min, Obtain tea extract 1.

[0036] The surface of the third product 1 is sprayed with wine with an alcohol...

Embodiment 2

[0039] This embodiment is a specific embodiment for preparing the composition product 2.

[0040] The destemmed tea leaves were dried at 75° C. for 45 minutes to obtain the first product 2 with a water content reduced by 30%.

[0041] The first product 2 was dried at 70° C. for 70 minutes to obtain the second product 2 with a water content reduced by 20%.

[0042] The water content of the second product 2 is reduced by 10% after being dried at 90°C for 80 minutes, and after standing to room temperature, the tea extract 2 is sprayed on the surface, cut into filaments with a width of 0.5-2.3 mm, and the third product 2 is obtained; Among them, the spraying amount of the tea extract 2 is 3ml / Kg of the third product 2, and the preparation method of the tea extract 2 is: 100g of fresh tea leaves are crushed to 25-35 mesh, dissolved in 1Kg of water, concentrated at 120°C for 60min, Obtain tea extract 2.

[0043] The surface of the third product 2 is sprayed with wine with an alcoh...

Embodiment 3

[0046] This embodiment is a specific embodiment for preparing the composition product 3.

[0047] The destemmed tea leaves were dried at 80° C. for 60 minutes to obtain the first product 3 with a water content reduced by 30%.

[0048] The first product 3 was dried at 90° C. for 65 minutes to obtain the second product 3 with a water content reduced by 20%.

[0049] The water content of the second product 3 is reduced by 10% after being dried at 80°C for 50 minutes, and after standing to room temperature, the tea extract 3 is sprayed on the surface, cut into filaments with a width of 0.5-2.3 mm, and the third product 3 is obtained; Among them, the spraying amount of the tea extract 3 is 4ml / Kg of the third product 3, and the preparation method of the tea extract 3 is: 100g of fresh tea leaves are crushed to 25-35 mesh, dissolved in 1Kg of water, concentrated at 90°C for 120min, Obtain tea extract 3.

[0050] The surface of the third product 3 is sprayed with wine with an alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com