Embedded structured asphalt pavement and construction method thereof

A technology of structural asphalt and construction method, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, and can solve the problems of cracks in the asphalt surface, large horizontal friction, and damage of the asphalt surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

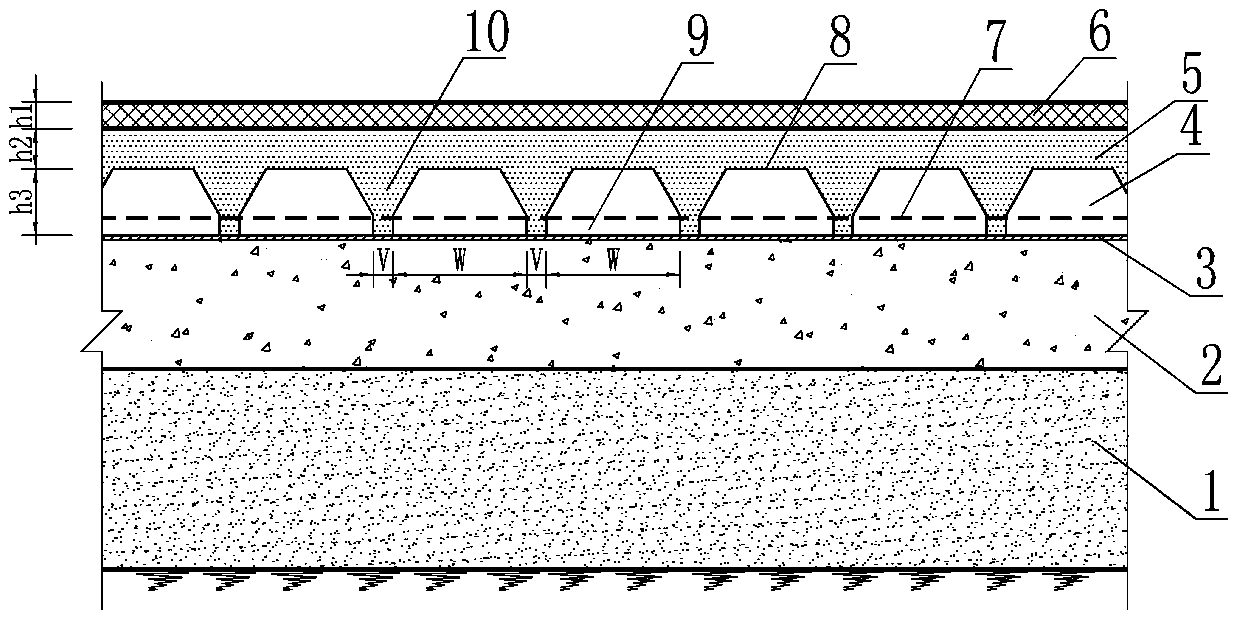

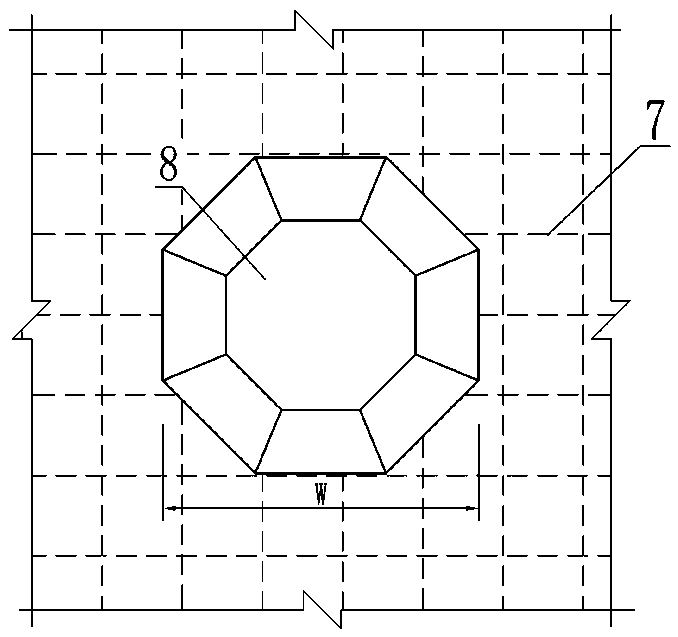

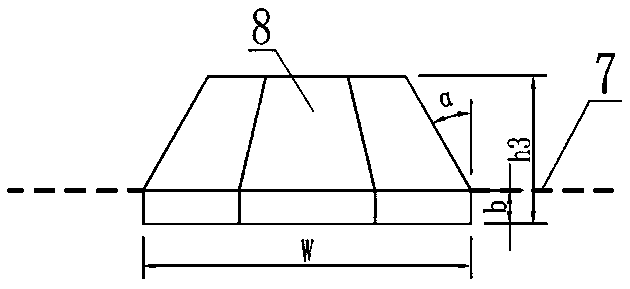

[0034] In order for those skilled in the art to better understand the present invention, in combination with Figure 1 to Figure 9 To further illustrate the present invention, the content mentioned in the embodiment is not to limit the present invention.

[0035] The present invention starts from the composition and structure of the pavement structure, and improves the lower layer 4 and the middle layer 5, which play a load-bearing role on the surface layer, and the two layers are fitted together to restrain each other, so as to reduce displacement, deformation and damage under load. Asphalt pavement with embedded structure is mainly composed of subbase layer 1, base layer 2, seal layer 3, lower layer 4, middle surface layer 5, and upper layer 6. The pavement structure diagram of the present invention is shown in figure 1 . The lower layer 4, the middle layer 5, and the upper layer 6 form an asphalt surface layer, wherein the lower layer 4 and the middle layer 5 are embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com