Mine underground gas-water slag separation system with dust collecting hood

A technology of separation system and dust collection cover, which is applied in mining equipment, flushing boreholes, borehole/well components, etc. It can solve the problems of high cost, mine gas exceeding the limit, and inconvenient use, so as to reduce weight and prolong service life , good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

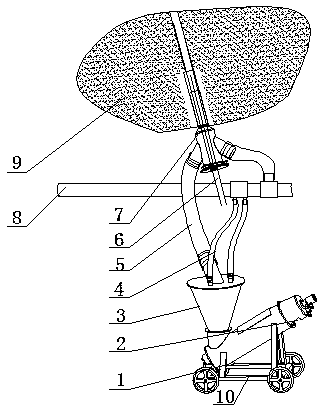

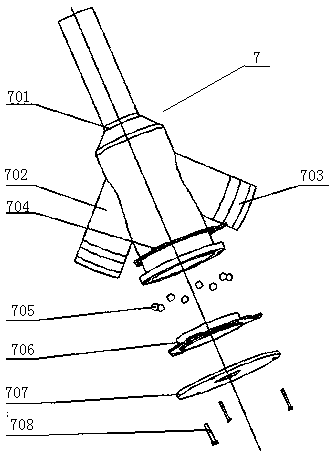

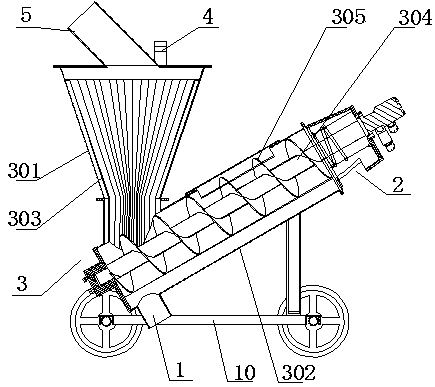

[0024] As shown in the figure, a mine gas-water-slag separation system with a dust hood includes a gas-water slag separation device 3, a drainage pipeline 4, a connecting pipeline 5, a drill pipe 6, a new type of dust hood 7 and The main negative pressure pipeline 8, the extended end of the new dust collecting hood 7 is fixed in the coal seam 9, the drill pipe 6 is located in the cylinder of the new dust collecting hood 7, the gas-water slag separation device 3 is connected to the new dust collecting hood through the connecting pipeline 5 One side of the cover 7 is connected, and the other side of the new dust collecting cover 7 is connected with the main negative pressure pipeline 8 through the connecting pipe. When the drill pipe 6 is rotated and drilled, the water flow in the coal seam 9 is mixed with coal powder to form coal water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com