Aerosol sprayer engine assembly and aerosol sprayer

An engine assembly, fog machine technology, applied in the direction of machine/engine, engine components, combustion engine, etc., can solve the problems of high power consumption, high power consumption, heavy fuel tank and equipment weight, etc., to reduce the weight of the air pump and operator difficulty, improving quality, reducing the effect of battery power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

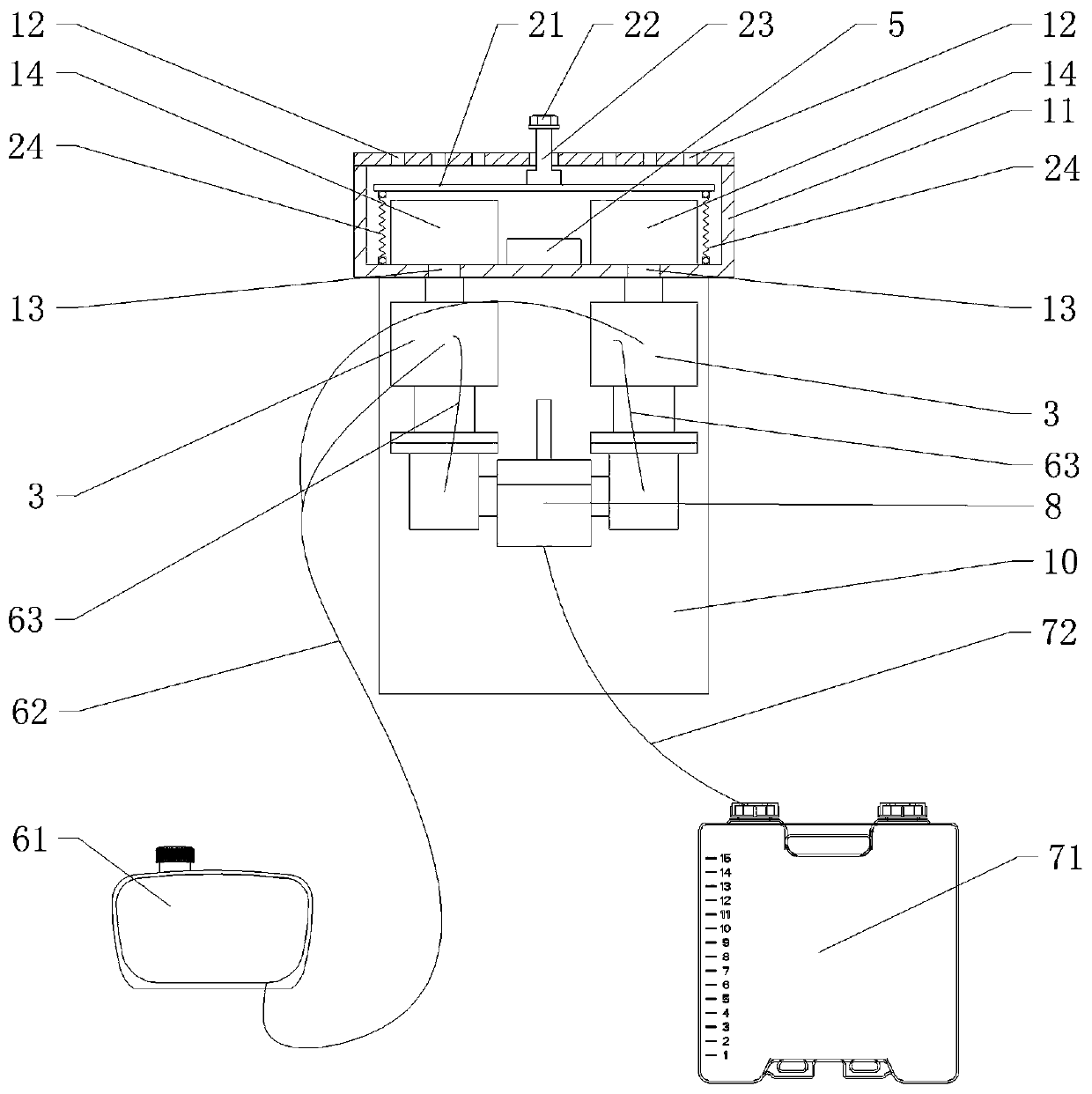

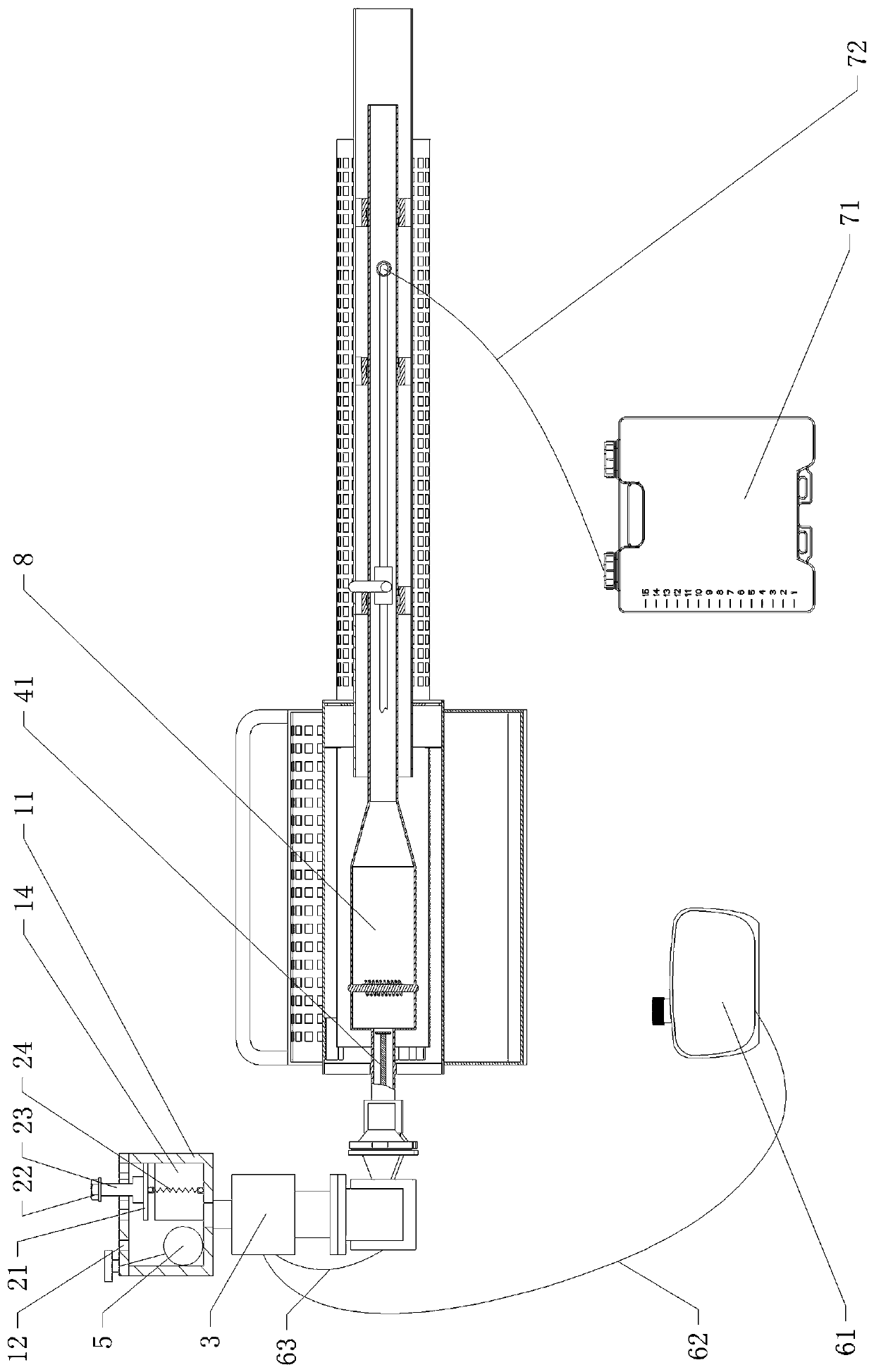

[0029] Embodiment 1: as Figure 1-3 As shown, the aerosol engine assembly includes an air supply device, an oil supply pipeline 62, a carburetor assembly, a combustion chamber, a spray pipe 73, a control device and a power supply.

[0030] The carburetor assembly is an integrated electronic ignition three-in-one carburetor assembly. The integrated electronic ignition three-in-one oiler assembly has the advantages of one-key start, one-key flameout, and carburetor atomization.

[0031] The carburetor assembly includes a carburetor atomizing device 3, an ignition device and a flameout device.

[0032] The gas supply device and the combustion chamber are respectively connected with the carburetor assembly, and the spray pipe 73 communicates with the combustion chamber.

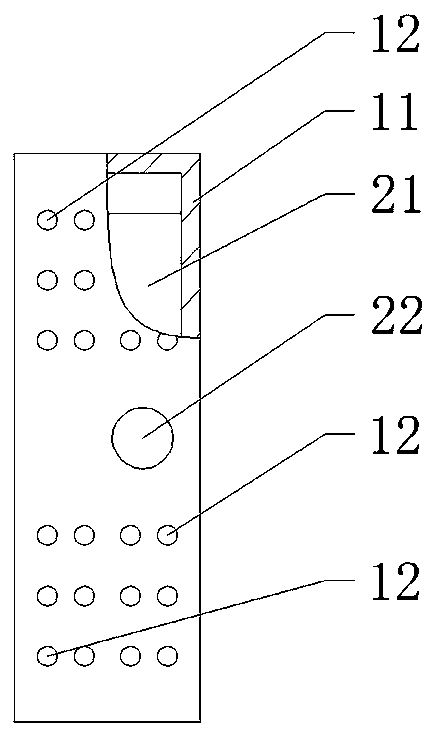

[0033] The air supply device includes an air chamber 11 , an air inlet 12 , an air outlet 13 and a fan 14 .

[0034] The air inlet hole 12 is located on the upper part of the air chamber 11 , specifically, the...

Embodiment 2

[0052] Embodiment 2: as Figure 1-5 As shown, the smoke machine includes an engine, an oil tank 61 and a medicine supply system.

[0053] The oil tank 61 communicates with the carburetor through an oil supply pipeline 62 , and the combustion chamber communicates with the carburetor through a return air pipeline 63 .

[0054] The medicine box 71 communicates with the medicine spraying pipe 73 through the medicine liquid pipe 72 .

[0055] In addition, a bracket 10 is also included for supporting devices such as the engine.

[0056] The medicine spray pipe 73 is provided with parts such as heat dissipation outside.

[0057] Engine content is with embodiment 1.

[0058] The advantages of the present invention are: the structure of the equipment room is improved, the fuel tank 61 and the medicine tank 71 are placed outside, and when in use, the weight of the fuel tank 61 and the medicine tank 71 does not need to be carried on the back, which greatly reduces the work burden.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com