Accelerometer chip and processing technology and accelerometer based on qos technology

An accelerometer and processing technology, applied in the direction of measuring acceleration, speed/acceleration/shock measurement, instruments, etc., can solve the problems of accelerometer accuracy and stability, low accuracy of quartz wet corrosion, and reducing the effect of differential motion, etc. , to achieve the effect of low cost, high precision dry etching and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to specific examples, which are to explain rather than limit the present invention.

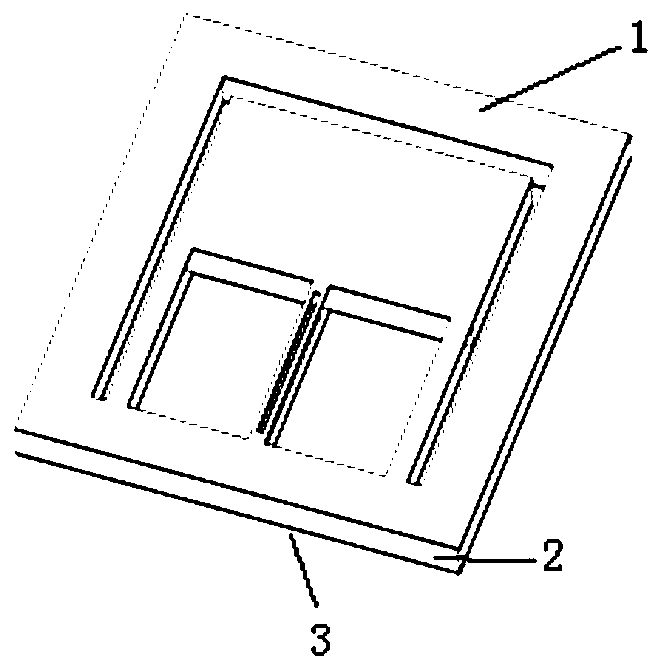

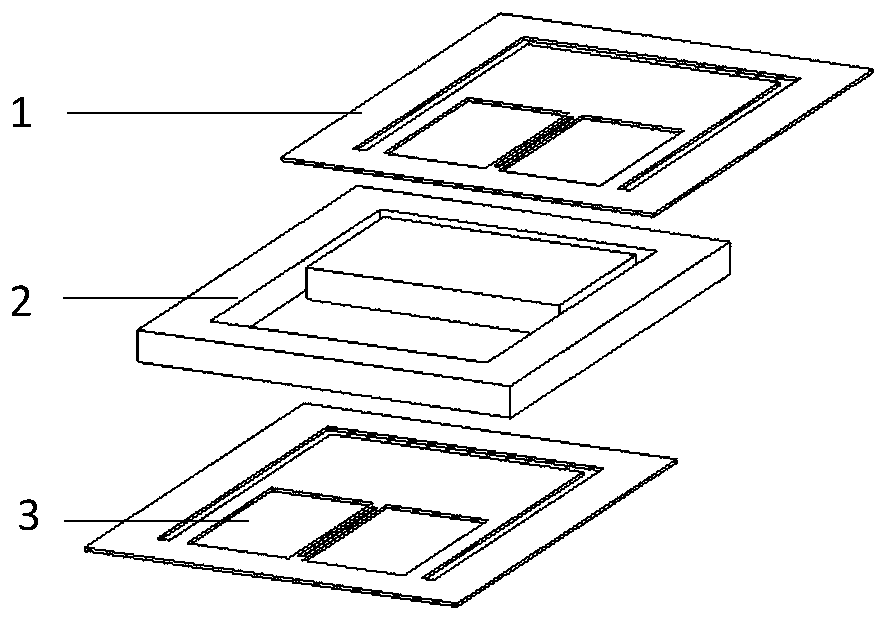

[0035] refer to figure 1 and 2 , Z-direction sensitive quartz vibrating beam accelerometer chip based on QoS process, including first quartz structure 1, silicon-based structure 2 and second quartz structure 3 in order from top to bottom, first quartz structure 1 and silicon-based structure 2 and silicon The base structure 2 and the second quartz structure 3 are both bonded and connected, and the first quartz structure 1 and the second quartz structure 3 have the same structure. The typical thickness of the first quartz structure 1 is 10-50 μm, which can be flexibly changed according to design and process requirements.

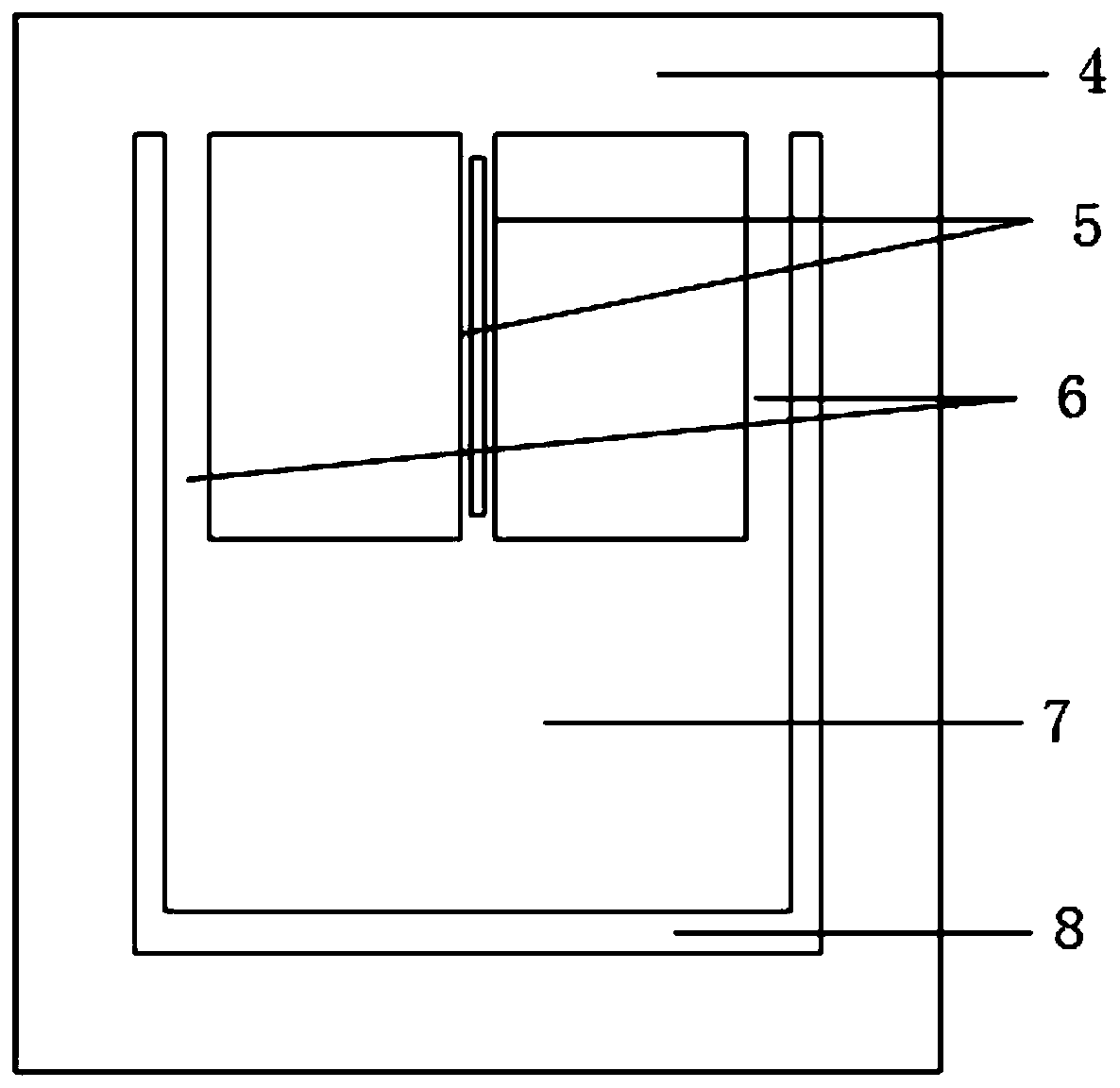

[0036] refer to image 3 The first quartz structure 1 includes a quartz frame 4, a double-ended fixed quartz tuning fork 5, a quartz support beam 6 and a quartz mass block 7; the quartz f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com