A temperature-controlled automatic maintenance system and method

An automatic and warm technology, applied in the control/regulation system, temperature control, non-electric variable control, etc., can solve the problem that the supply system is difficult to meet its requirements, affect the battery life, affect the battery charging efficiency, etc. The effect of reducing accuracy requirements, simple and convenient replenishment, and improving safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

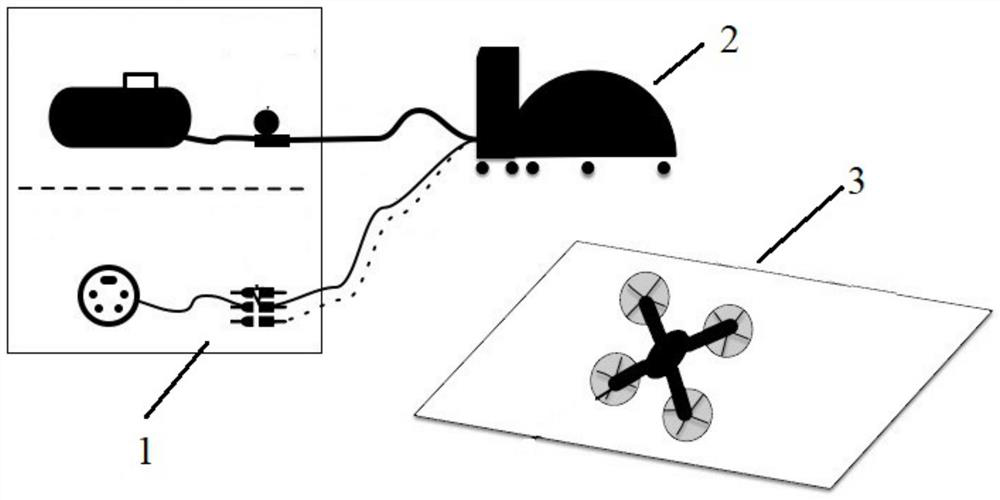

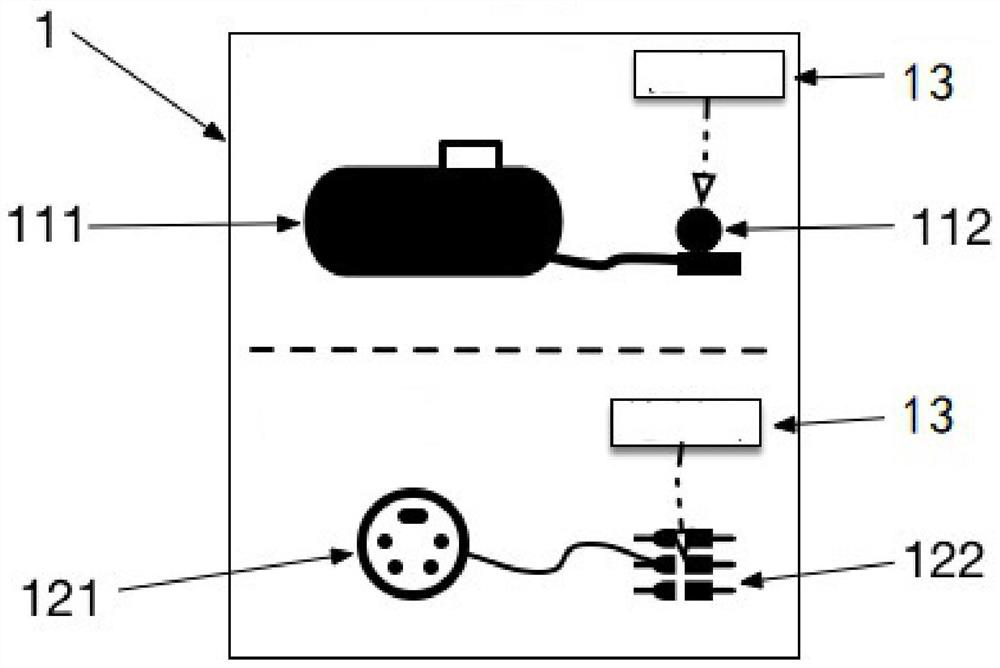

[0046] see figure 1 , this embodiment provides a temperature-controlled automatic maintenance system, including: a supply station 1, a supply machine 2, and a supply platform 3;

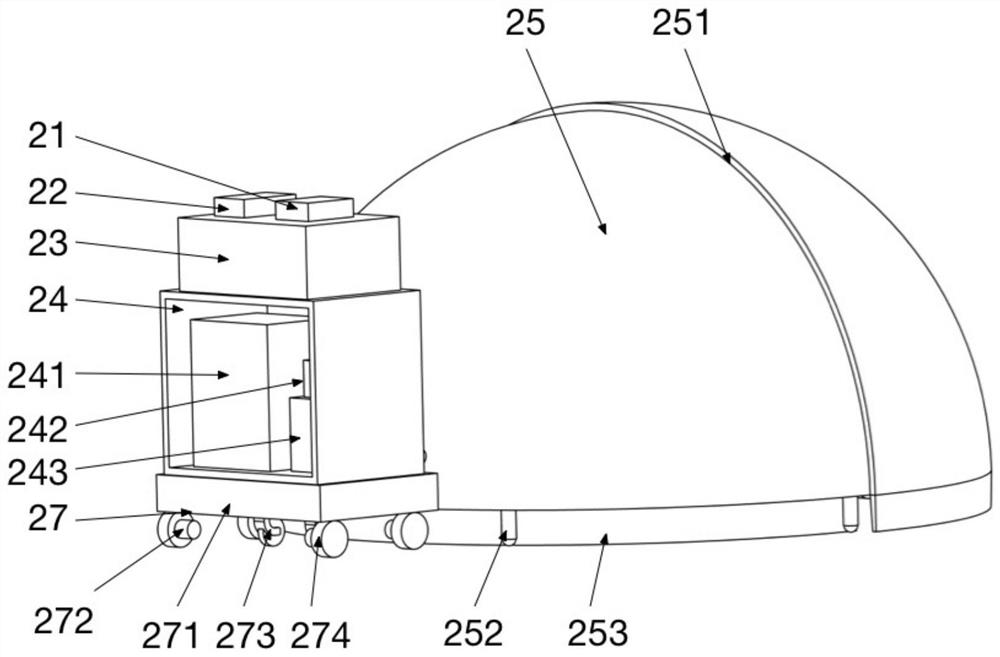

[0047] The supply station 1 is used to output supply resources, the supply platform 3 is used to park and fix the mobile equipment, the supply machine 2 is used to transport the supply resources to the mobile equipment, the supply station 1 is equipped with a supply controller 13 for the supply control of supply resources, and the supply The machine 2 includes a thermostat box 24, an airflow arm 264, a supply arm 261, and a control module 21; wherein,

[0048] The temperature regulating box 24 is provided with an air outlet 244 and an air inlet 245, and the temperature regulating box 24 is used for temperature regulation and delivery control of the gas;

[0049] The top of the air flow arm 264 is provided with a vent interface 266 connected to the air outlet 244 of the thermostat box 24, and the ven...

Embodiment 2

[0077] see Figure 7 , this embodiment provides a temperature-controlled braking maintenance method applied in Embodiment 1, including the following steps:

[0078] S1: Detect and judge whether the mobile equipment parked on the supply platform is parked. If the parking is completed, fix the mobile equipment and feed back the supply signal;

[0079] S2: After receiving the supply signal, drive the supply machine to move its position to align the supply machine with the mobile device. At the same time, detect the positional relationship between the supply machine and the mobile device in real time, and adjust the position movement of the supply machine in real time according to the positional relationship. To realize the connection of the temperature adjustment line, supply line and communication line between the supply machine and the mobile device;

[0080] S3: Adjust the temperature of the working temperature sensitive parts of the mobile device through the temperature adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com