Spiral-flow-type automatic mud scraping and filtering system and method

A filtration system and cyclone technology, applied in the field of water treatment, can solve the problems of low filter life and filtration efficiency, difficult to effectively remove, etc., and achieve the effect of improving removal effect and removal efficiency, efficient dispersion and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

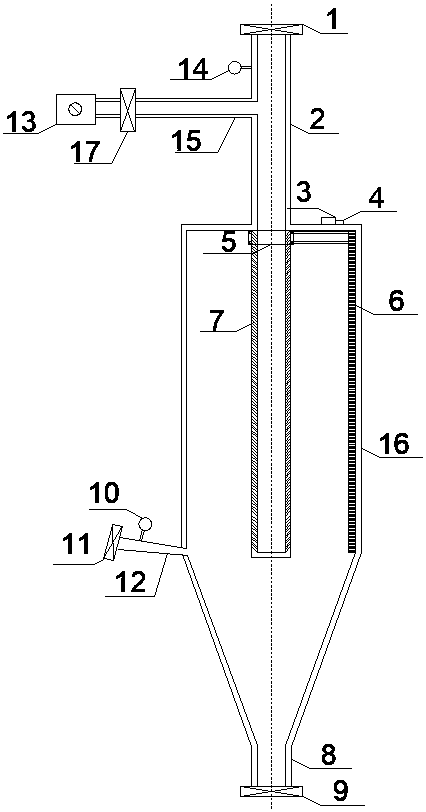

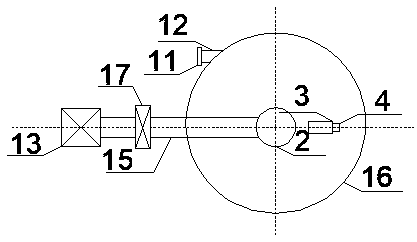

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

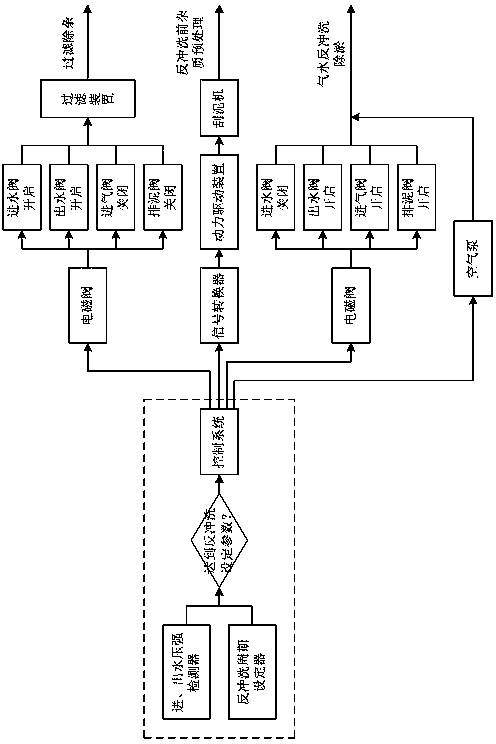

[0027] The invention provides a swirl type automatic mud scraping filter system and method that can effectively prevent impurities from accumulating inside the filter. The filter system includes a filter device and a control system. There is a water inlet pipe, a mud discharge pipe at the bottom, a laminated filter and an automatic mud scraper in the center of the filter device. The inlet pipe, outlet pipe, air inlet pipe and mud discharge pipe are all equipped with solenoid valves, which are regulated by the control system to realize the conversion of filtration and backwashing modes. The water inlet pipe is tapered, and has a horizontal inclination angle of 5~10° with the upper end of the tapered outer wall of the filter device shell, so as to use the swirling water inlet method to achieve the purpose of "swirling sand sedimentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com