Piston-type flotation machine

A flotation machine and piston-type technology, applied in flotation, solid separation, etc., can solve the problems of excessive turbulence in the flow field, affecting the flotation effect, particle shedding, etc., and achieve the effect of increasing the collision rate and quickly and effectively mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

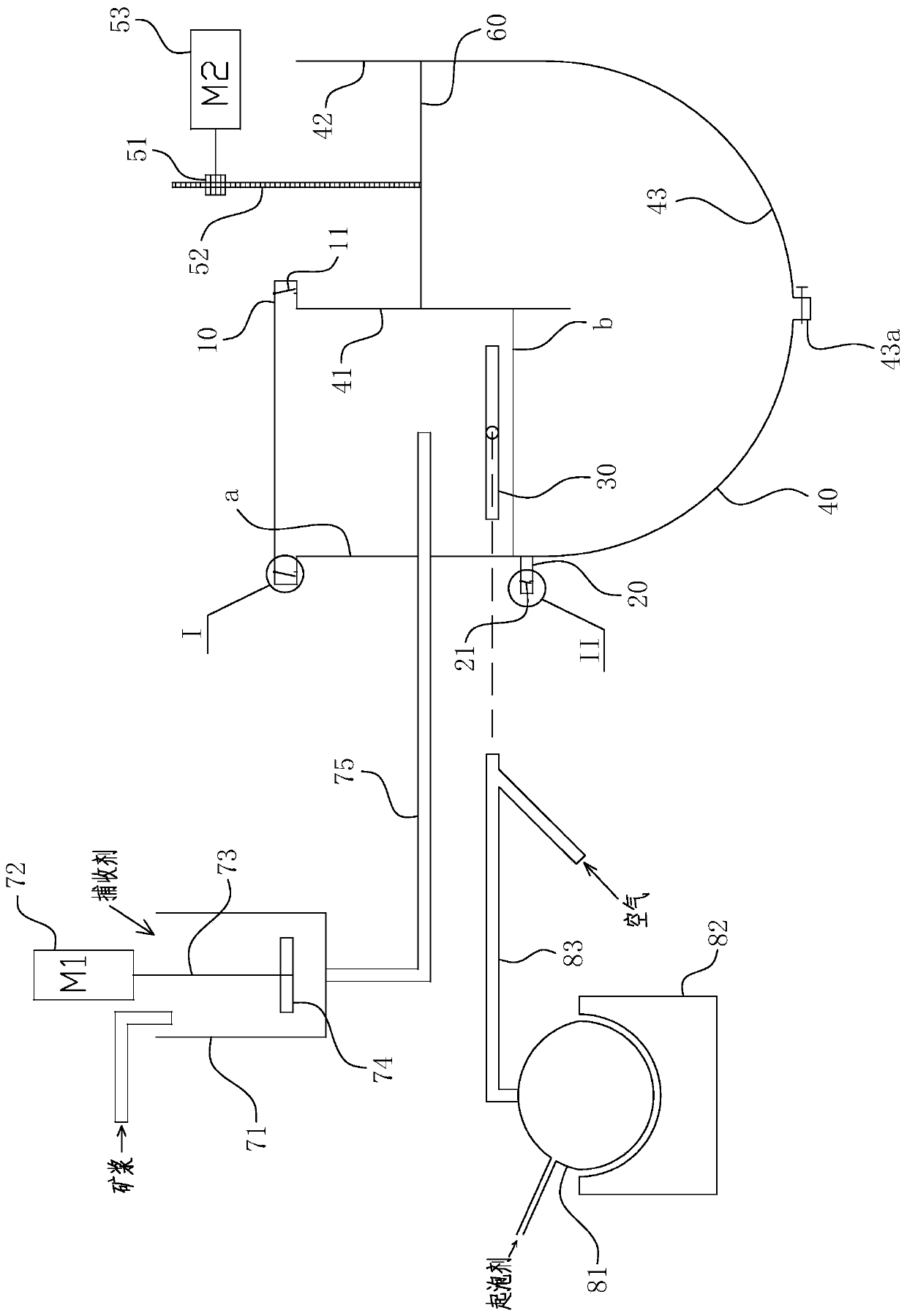

[0039] For ease of understanding, combined here Figure 1-5 , the specific embodiments of the present invention are further described as follows:

[0040] The specific components of the present invention are divided into several major modules, including: a flotation cell a, a piston part 60, a power assembly, a stirring assembly and a foaming agent vaporization assembly. in:

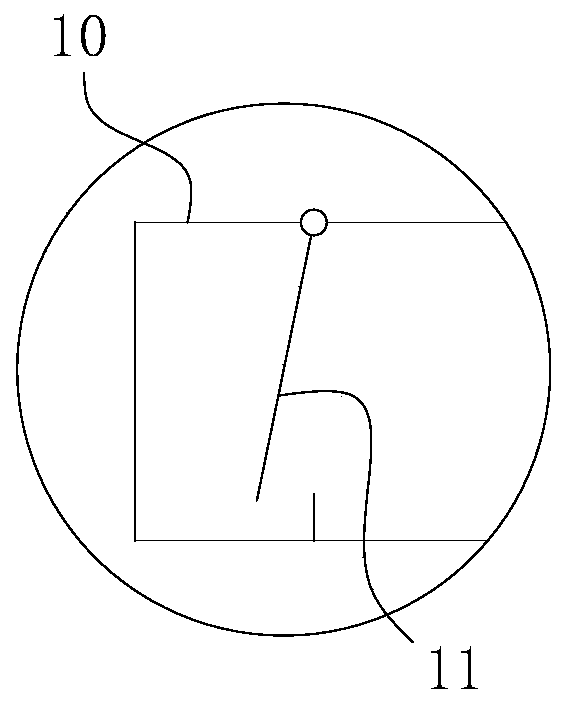

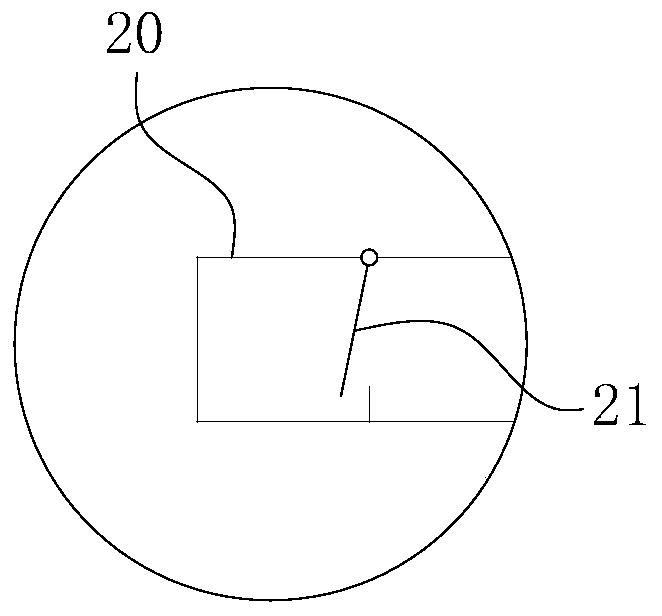

[0041] Flotation cell a and piston part 60 are integrated in such as figure 1 Inside the U-shaped tube 40 shown. The shape of the U-shaped tube 40 is in the shape of a tank with an opening facing upwards, and a vertical partition is arranged in the middle of the tank, thereby forming a U-shaped lumen structure of the U-shaped tube 40 . For the U-shaped tube 40, such as figure 1 As shown, a horizontal liftable bed b is arranged at the left pipe section 41 , and a horizontal liftable piston part 60 is arranged at the right pipe section 42 . Both the piston part 60 and the bed b form a sealing fit with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com