Efficient grinding and polishing system and method for outer surface of environment-friendly workpiece

An external surface and environment-friendly technology, applied in grinding/polishing equipment, grinding/polishing safety devices, grinding workpiece supports, etc., can solve problems such as fluttering, high production management costs, and low processing efficiency, and achieve surface grinding Consistent quality, low production management costs, and the effect of improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

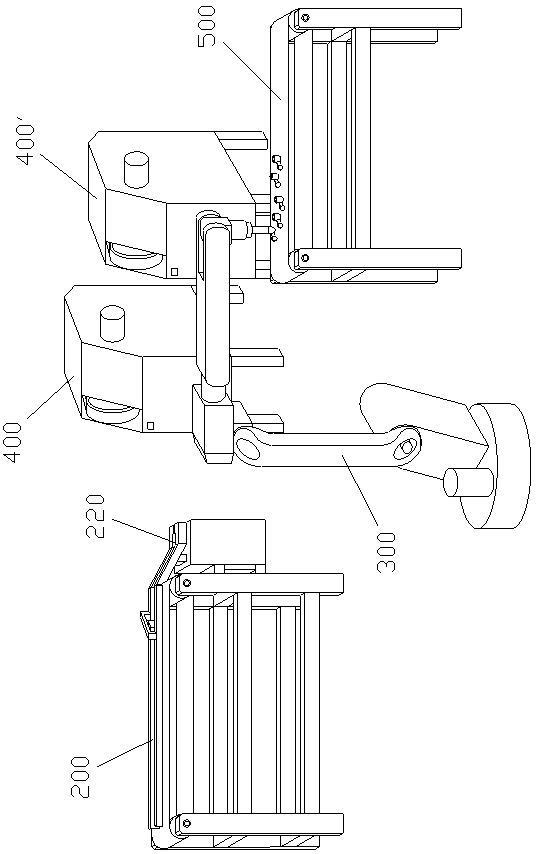

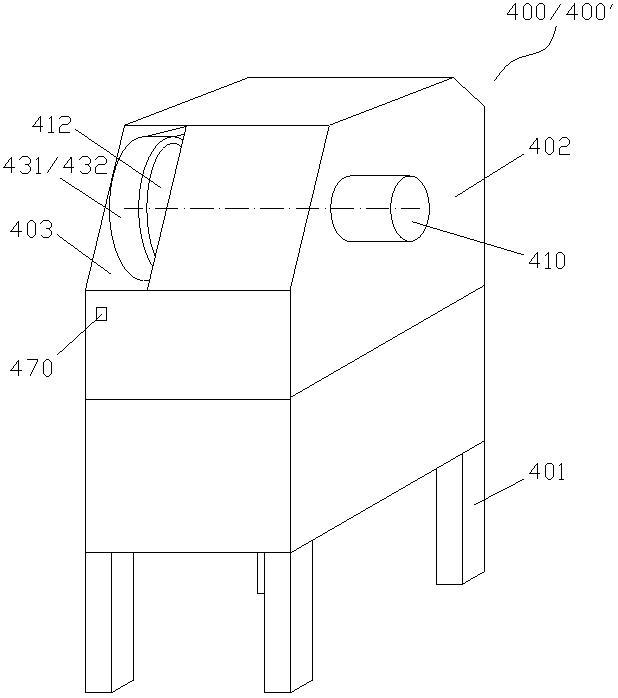

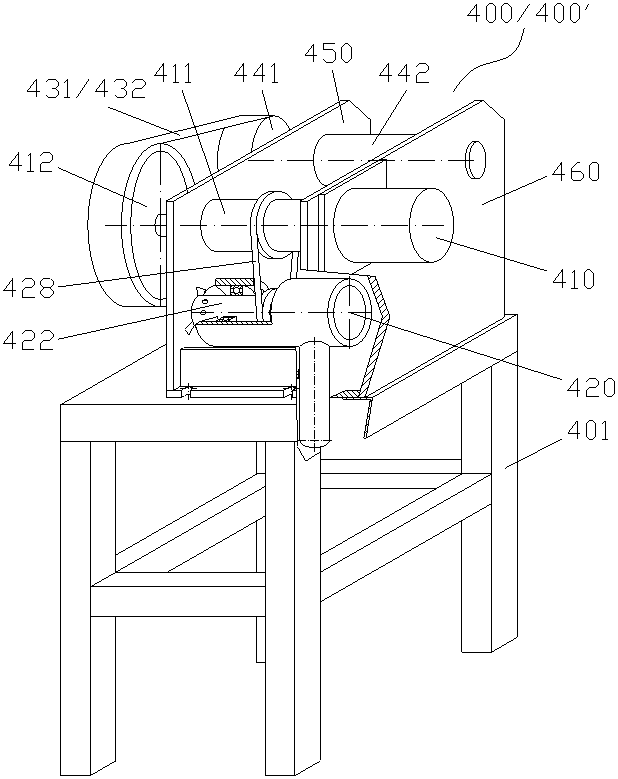

[0033] Such as Figure 1~4 As shown, an environment-friendly high-efficiency grinding and polishing system for the outer surface of a workpiece includes a robot 300, a grinding machine 400 and a polishing machine 400', and the grinding machine 400 and the polishing machine 400' are distributed around the robot 300. The grinding machine 400 and the polishing machine 400' are respectively equipped with a proximity switch 470 for sensing the arm of the robot 300, and the respective motors of the proximity switch 470 and the grinding machine 400 and the polishing machine 400' are electrically connected to the controller; wherein the proximity switch 470 Can be specifically installed on the housing 402 . When the arm of the robot 300 clamps the workpiece 10 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com