Light steel building waterproof parapet and construction method thereof

A technology for building waterproofing and parapet walls, applied in the field of light steel keel systems, can solve problems such as easy cracking of waterproof mortar, conflicts in construction technology, large differences in thermal expansion and contraction coefficients of steel and mortar, etc., to prevent water leakage and water seepage. Good, the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

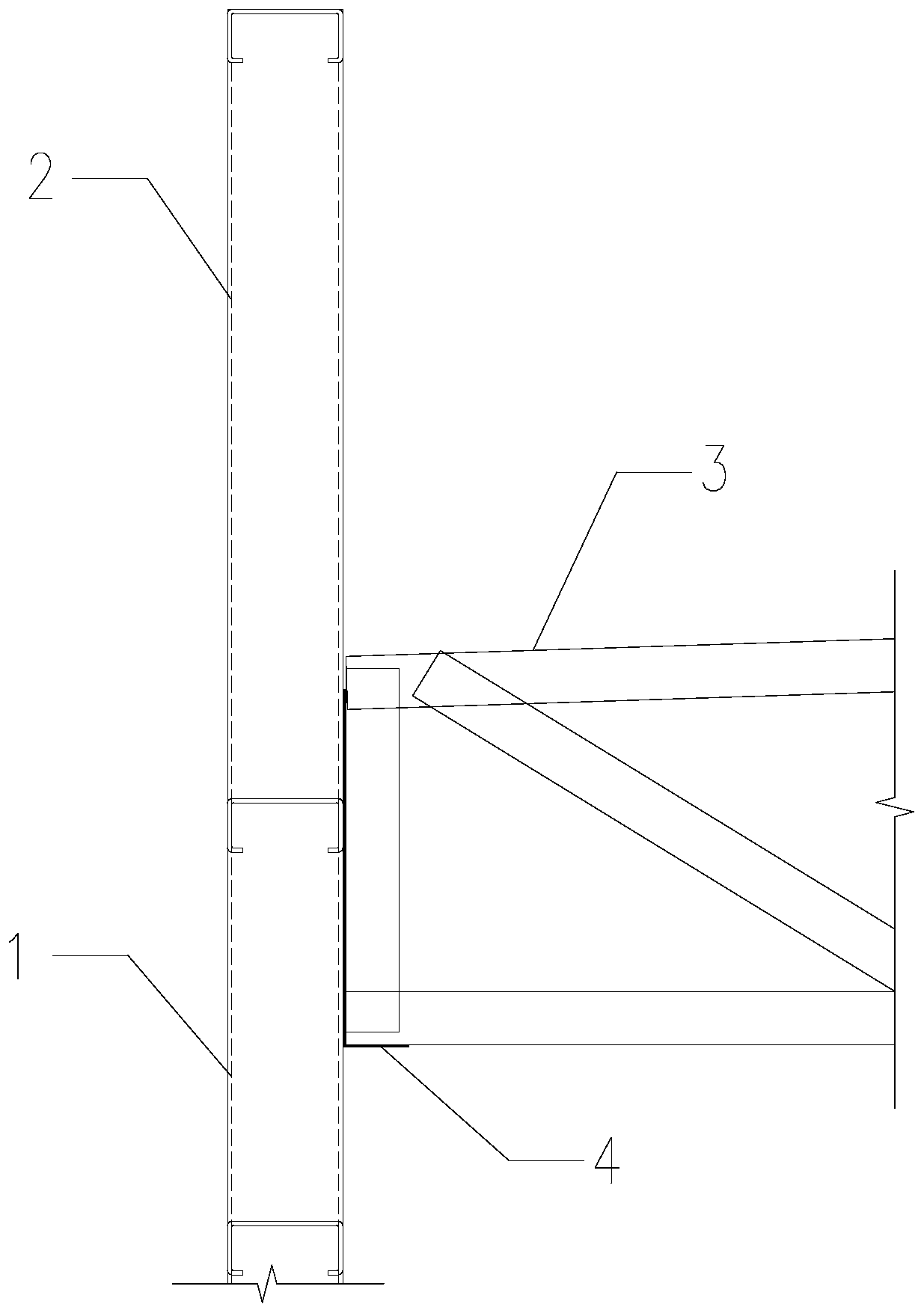

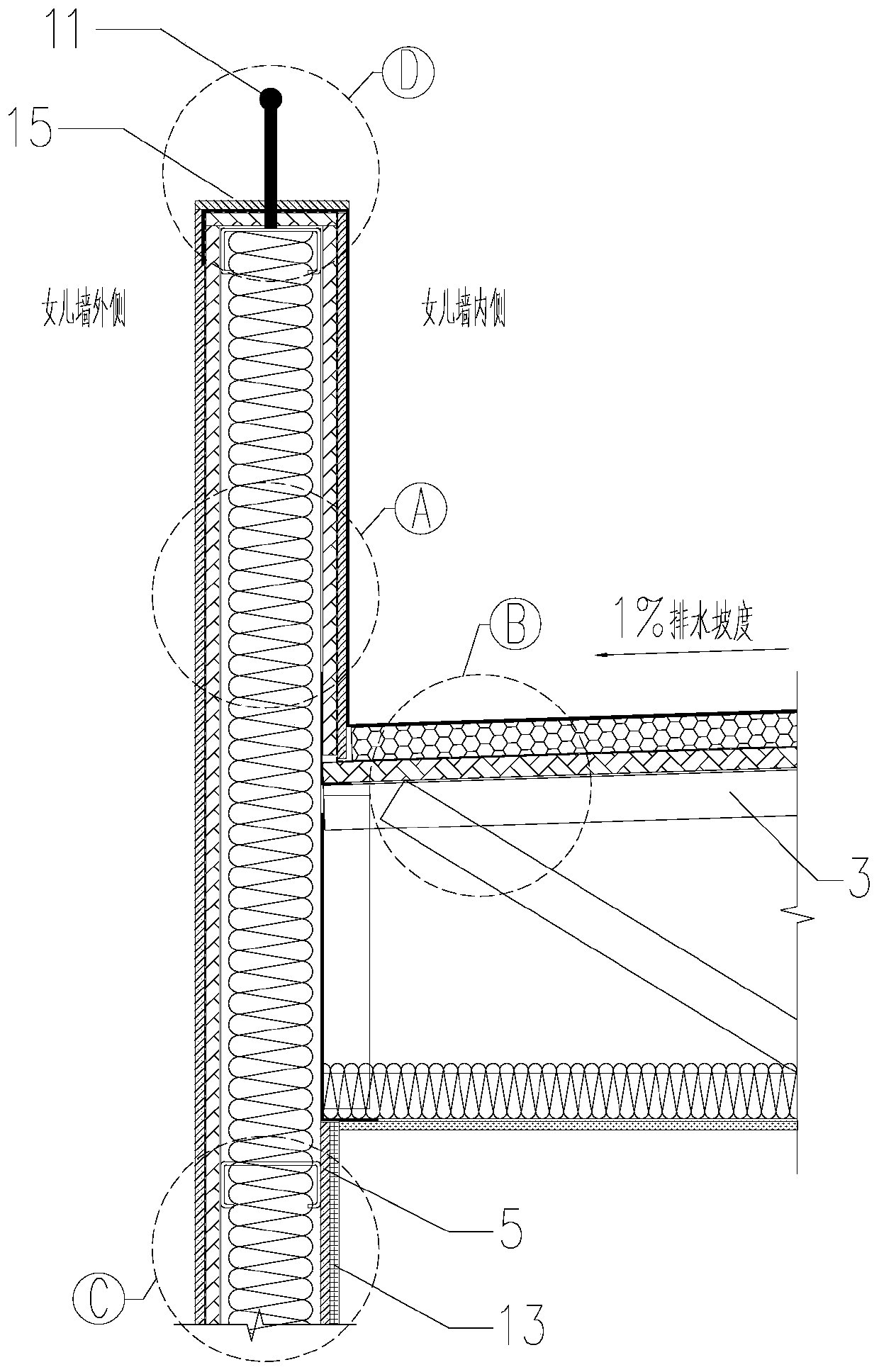

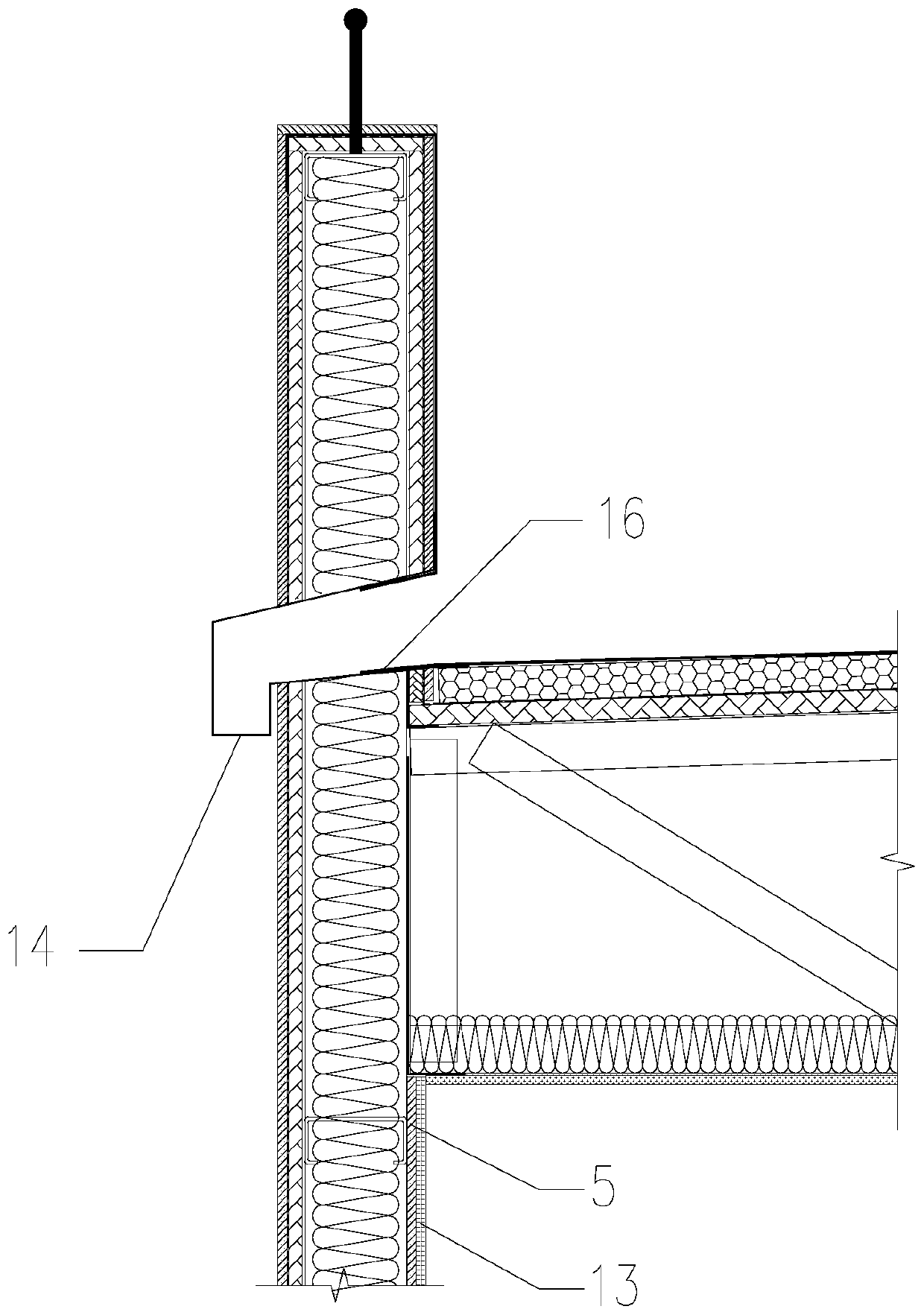

[0043] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 Shown in is the cross-section of the waterproof parapet of a light steel building, which is used for flat roofs with parapets in civil buildings. Since the water leakage problem of flat roofs with parapets has always been a long-term problem faced by civil buildings, it cannot be treated with asphalt and mortar. To meet the construction requirements of dry work, the use of waterproofing agent cannot meet the effect of anti-cracking and waterproofing for long-term use.

[0044]The building frame of the present invention consists of cold-formed thin-walled light steel keels 10 to form the wall frame 1 of the wall and the truss 3 on the roof of the building. It is usually a metal folding part, which is fixedly connected to the wall frame and truss at the same time by bolts. The wall frame is set vertically. Usually, the exterior wall of the building and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com