Replaceable shield tunneling machine cutterhead center rotary joint in tunnel and maintenance method

A technology of central rotary joint and shield machine, which is applied in the field of shield machines, can solve the problems of consuming a lot of manpower and material resources, sudden changes in soil pressure, and increased construction costs, so as to reduce downtime, prevent sudden pressure changes, and reduce consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

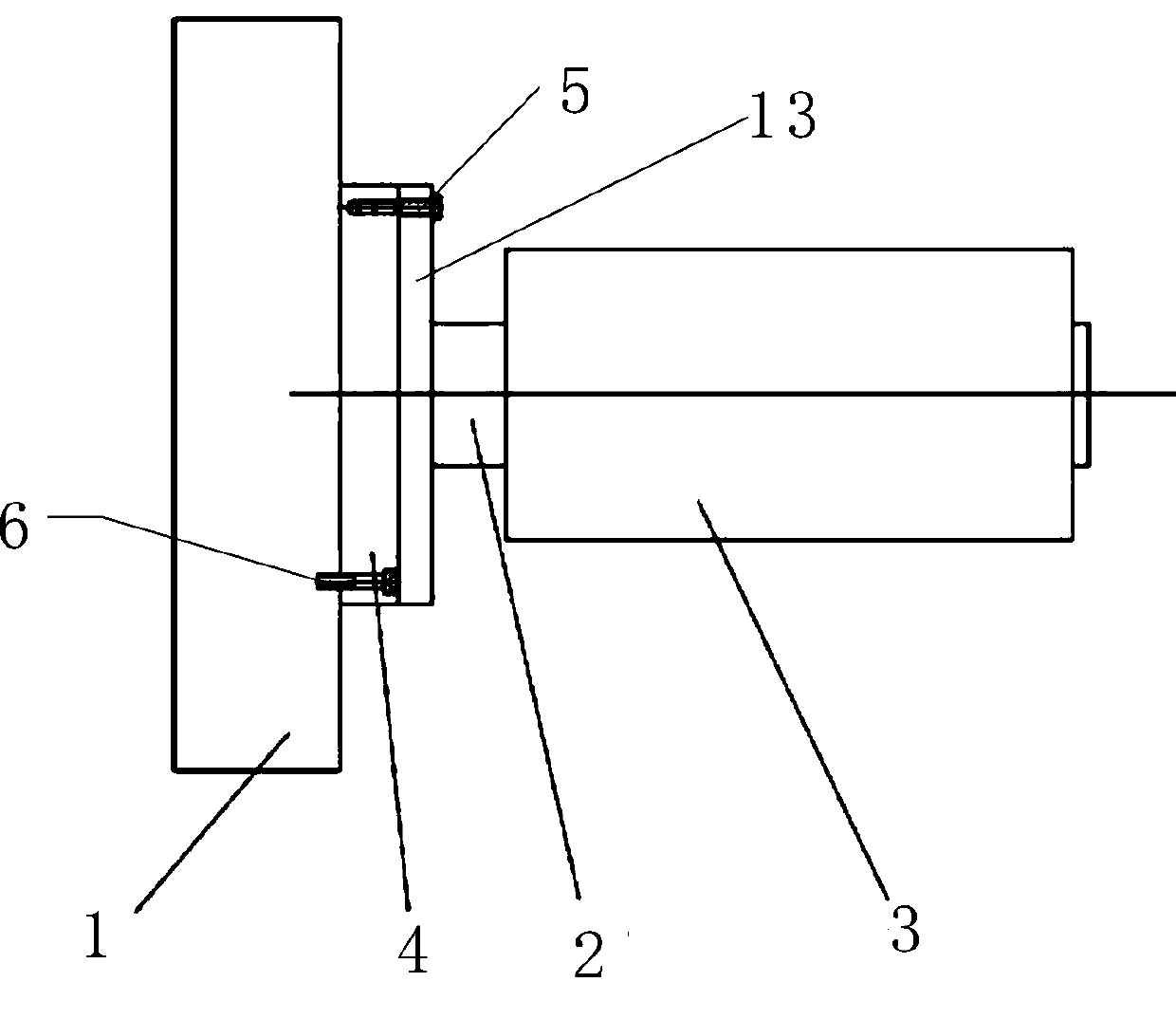

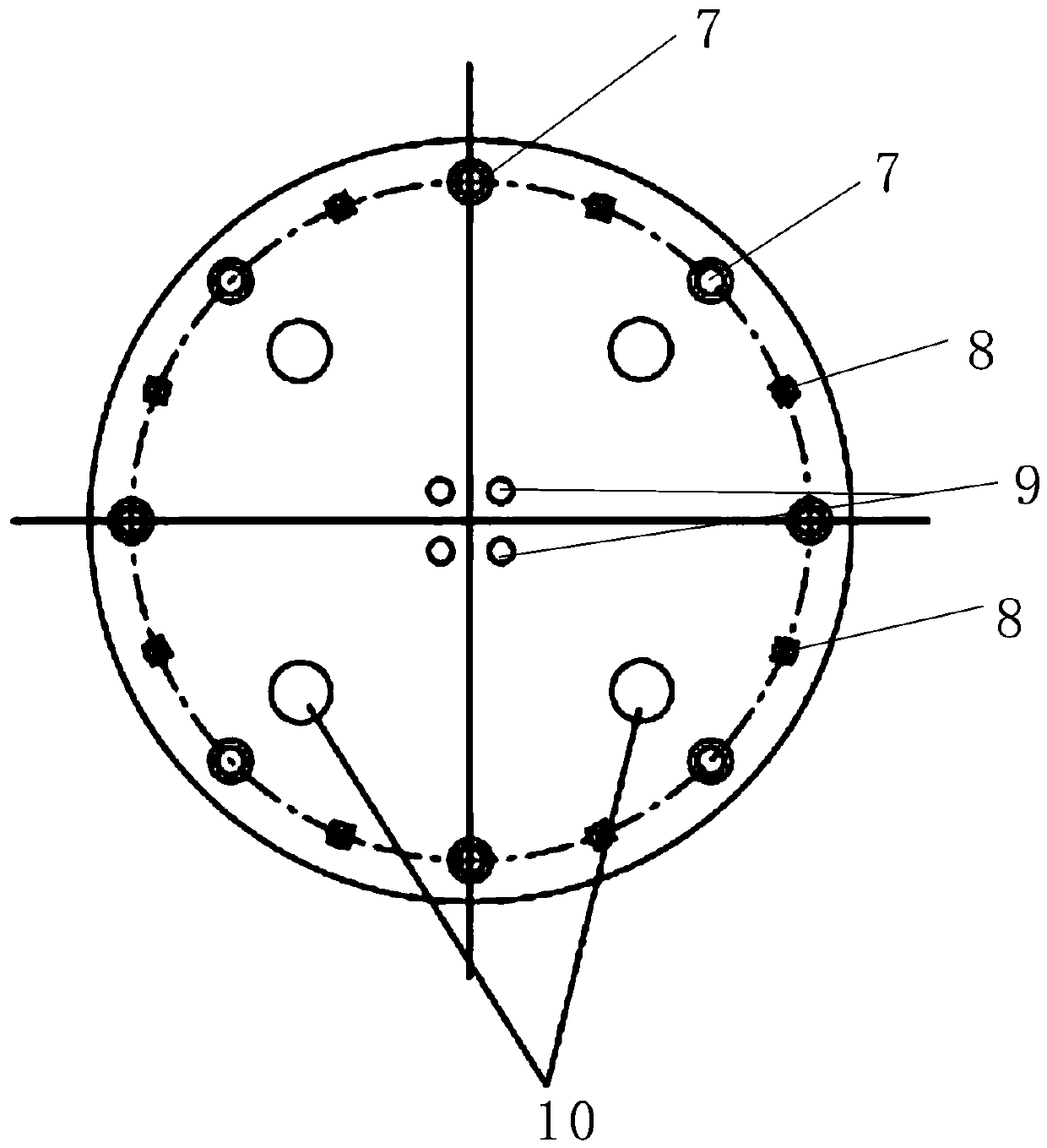

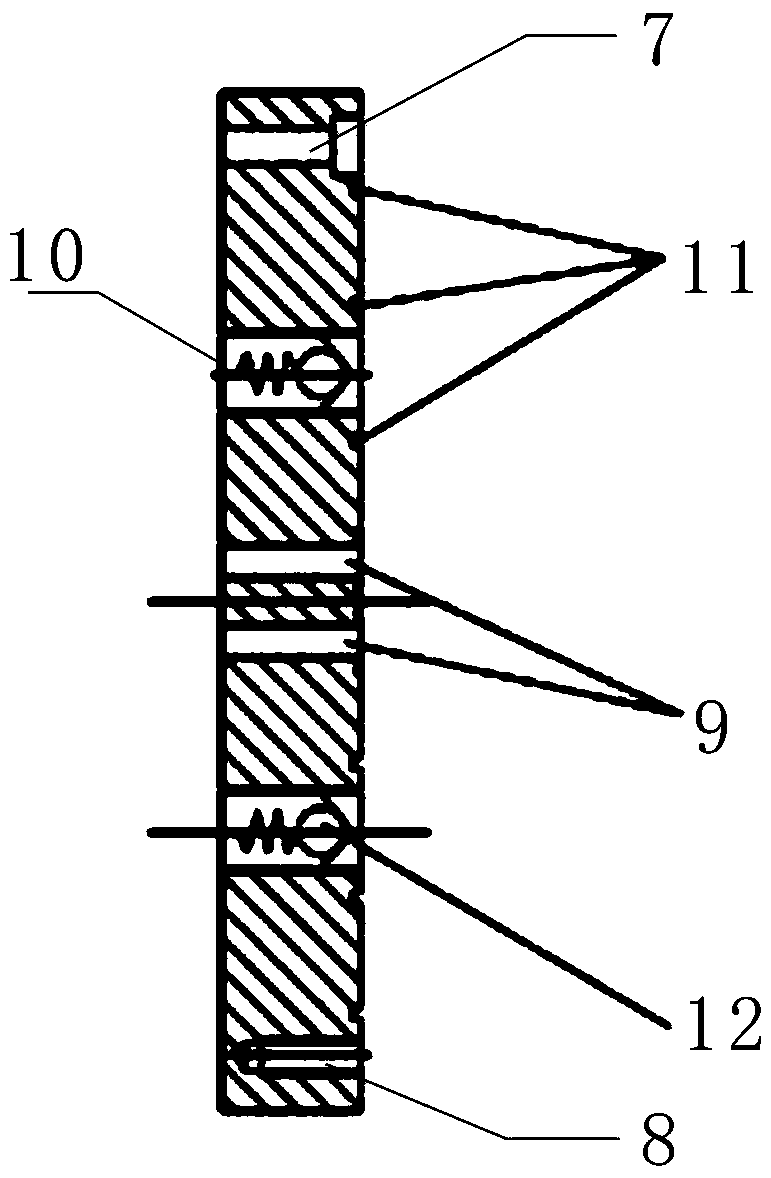

[0027] A replaceable central rotary joint of the shield machine cutterhead in the tunnel described in conjunction with the accompanying drawings includes: a casing 3, a central rotary shaft 2 is arranged inside the casing 3, a joint 13 is provided at the end of the central rotary shaft 2, and the joint 13 is connected with the cutter head 1, a one-way transition plate 4 is arranged between the joint 13 and the cutter head 1, and a number of first bolt holes 8 and second bolt holes 7 are evenly arranged on the edge circumference of the one-way transition plate 4, and the one-way The transition plate 4 is provided with several one-way valve embedding holes 10 and hydraulic oil hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com