A Hall thruster mounting bracket

A Hall thruster and mounting bracket technology, applied in thrust reversers, machines/engines, utilizing plasma, etc., can solve the problems of exposed air supply pipelines and circuits, and achieve the effect of solving the load bearing problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

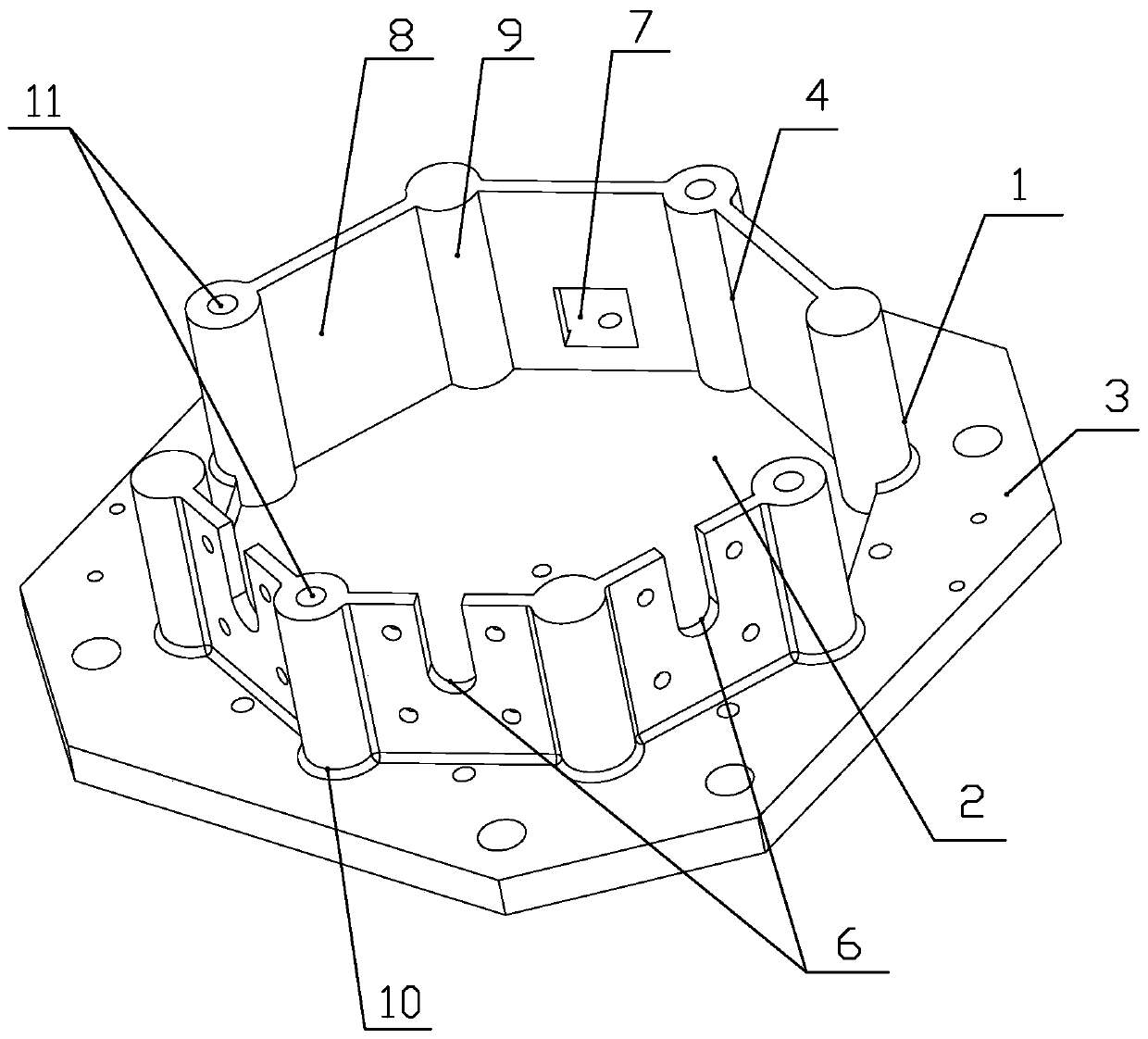

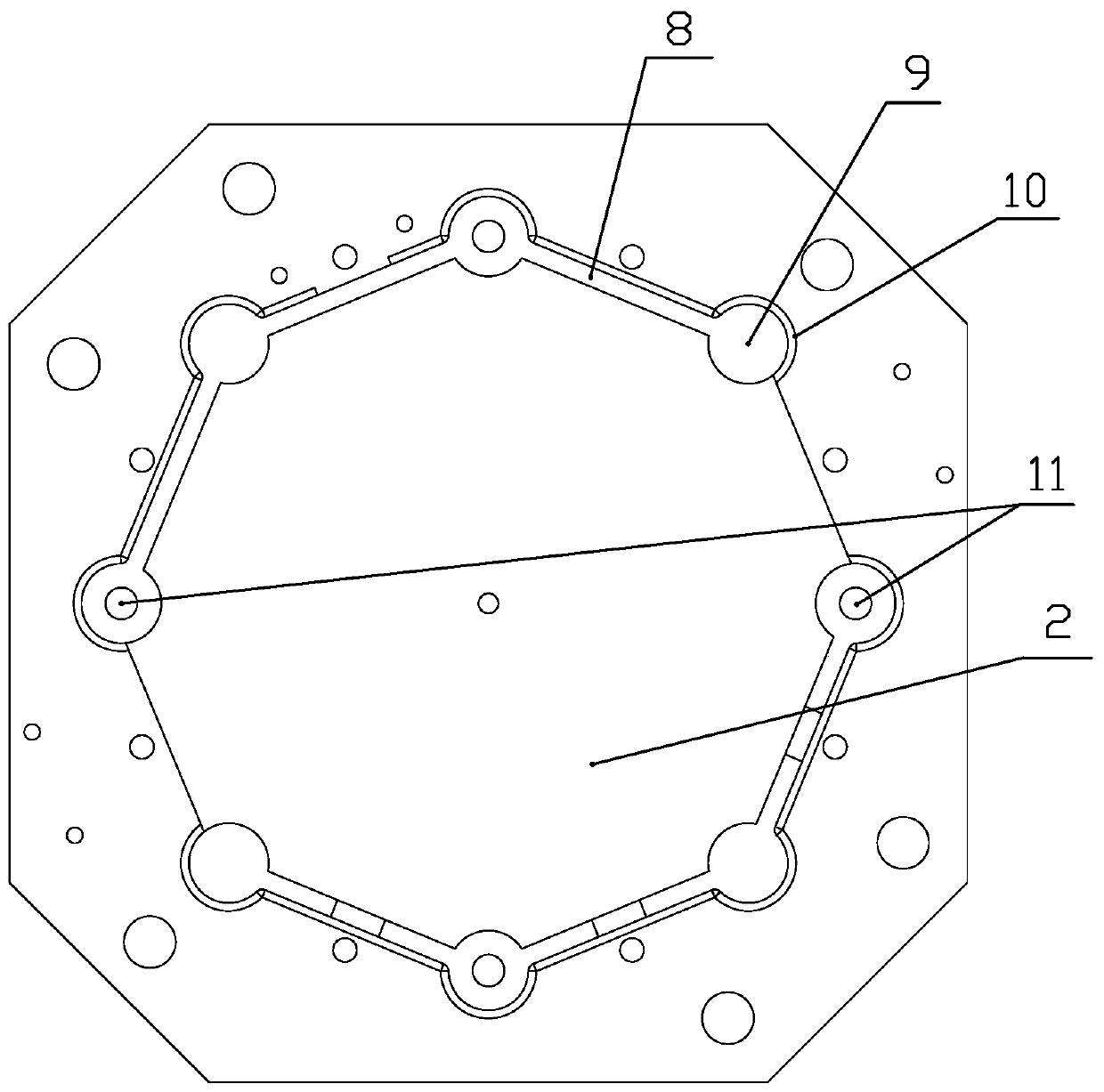

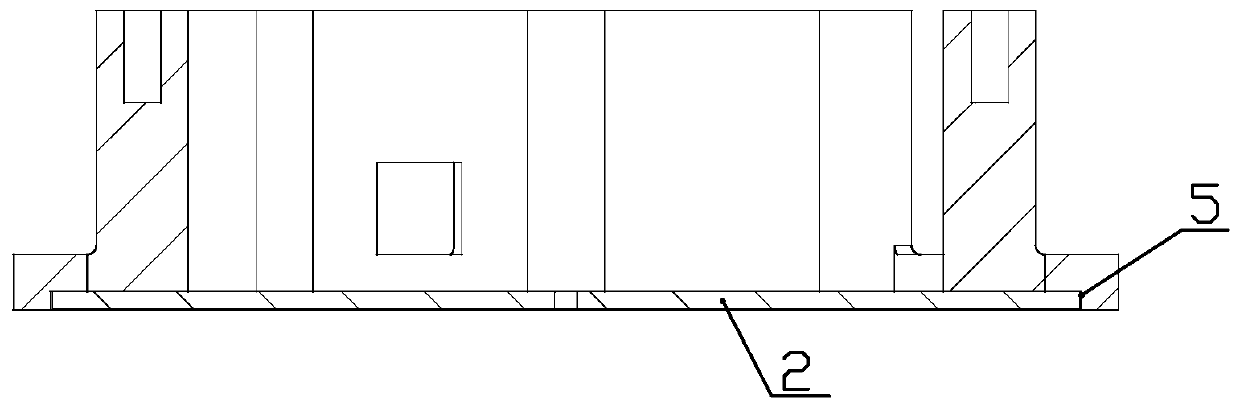

[0017] Specific implementation mode one: combine Figure 1~3 Describe this embodiment, a Hall thruster installation bracket, which includes a bracket main body 1 and a bottom plate 2, the bracket main body 1 includes a positioning plate 3 arranged horizontally and two supports 4 vertically arranged above the bottom plate 2, The middle part of the positioning plate 3 is vertically provided with a stepped through hole 5 whose inner diameter is small at the top and large at the bottom. Two support members 4 are arranged oppositely and their lower parts are all fixed on the small hole inner wall of the step through hole 5. Each support member 4 are all arranged with the inner wall of the small hole of the stepped through hole 5. One of the support members 4 is provided with a number of openings 6 with upward openings, and the other support member 4 is horizontally provided with wire holes 7. The end of each support member 4 There is a gap between each part and the end of another s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com