Test board and method for etching uniformity analysis

A test method and test board technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low work efficiency, inaccurate detection and analysis, etc., and achieve the effect of improving accuracy, improving detection and analysis efficiency, and reducing the steps of marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The production process of PCB generally includes core board cutting → negative film making inner layer circuit → pressing to make production board → drilling → sinking copper → full board electroplating → positive film process to make outer layer circuit → making solder mask layer → surface treatment → forming A PCB is produced.

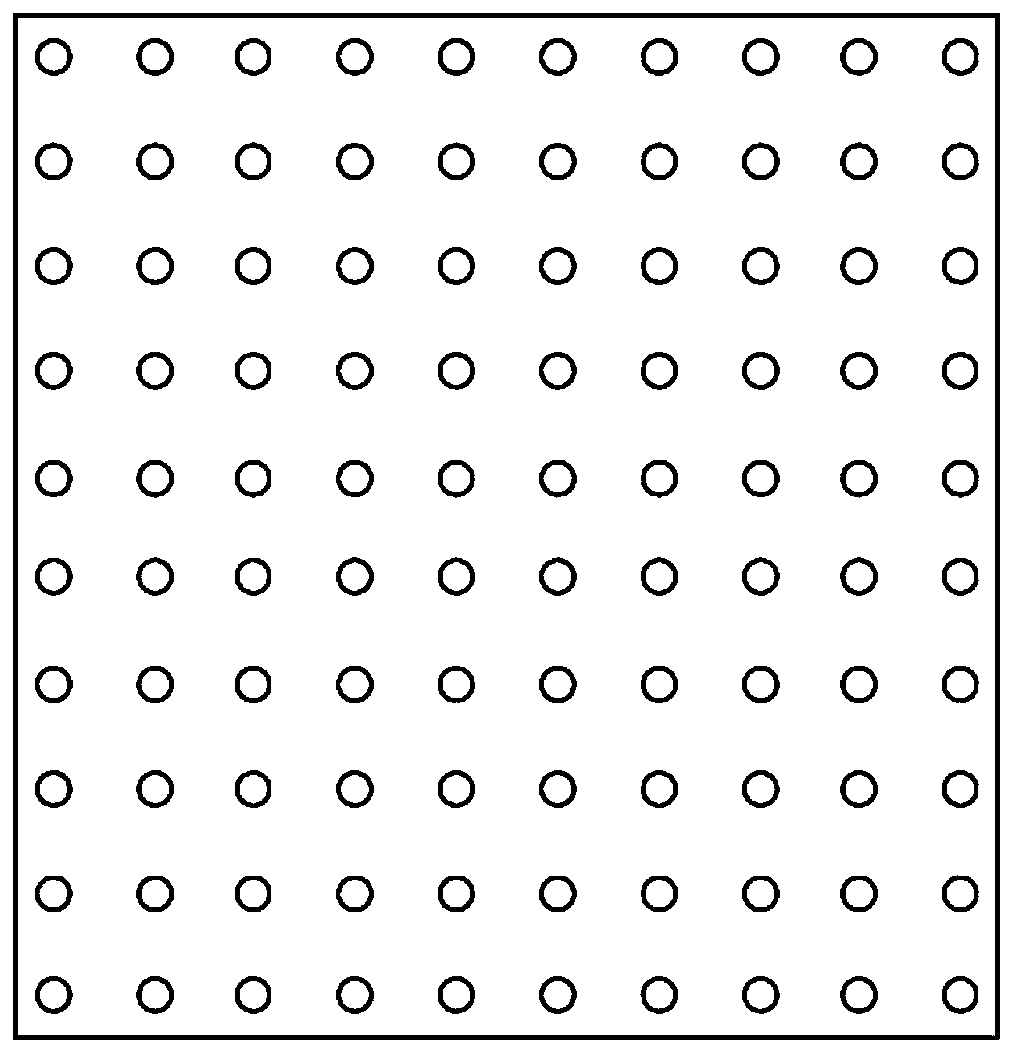

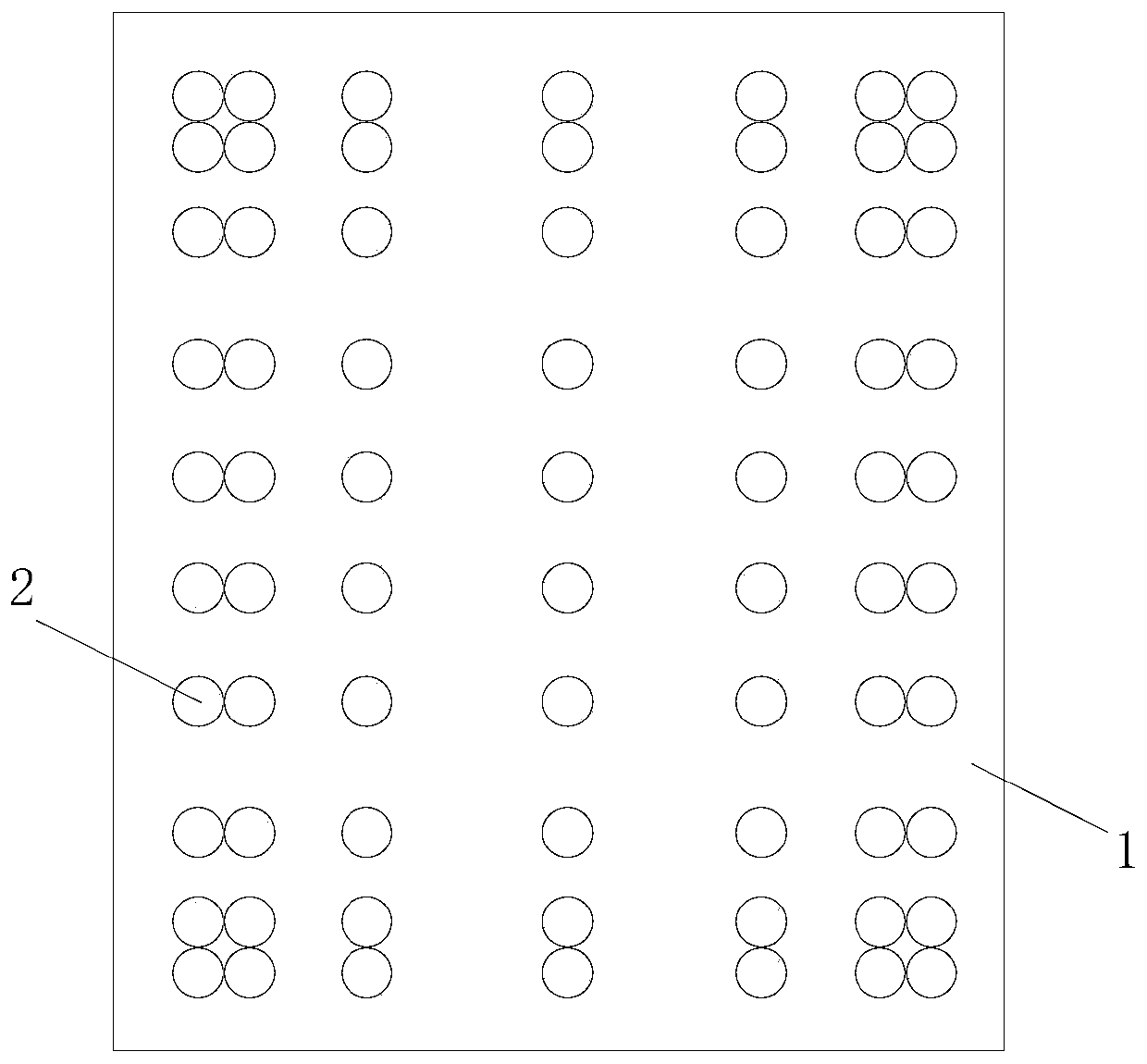

[0024] In the circuit manufacturing process, the uniformity of etching is one of the important factors that cannot be ignored among the many influencing factors of fine circuit boards. The etching uniformity after copper thickness etching on the board surface is detected and analyzed, and then the etching parameters in the PCB production process are adjusted, but the selection of measurement points on the PCB surface determines the correctness of the analysis of copper thickness etching uniformity; Because when the PCB is etched through the horizontal etching line, an "etching solution pool" will be formed in the middle of the upper surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com