Tunnel boring machine supporting cylinder joint vibration condition monitoring method

A technology for supporting oil cylinders and joints, which is applied to vibration measurement in solids, measuring vibrations, measuring devices, etc., which can solve the complex and changeable working environment, the troublesome measurement point layout, and the lack of research on vibration monitoring solutions at the joints of supporting oil cylinders, etc. problems, to achieve the effect of preventing emergencies, safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

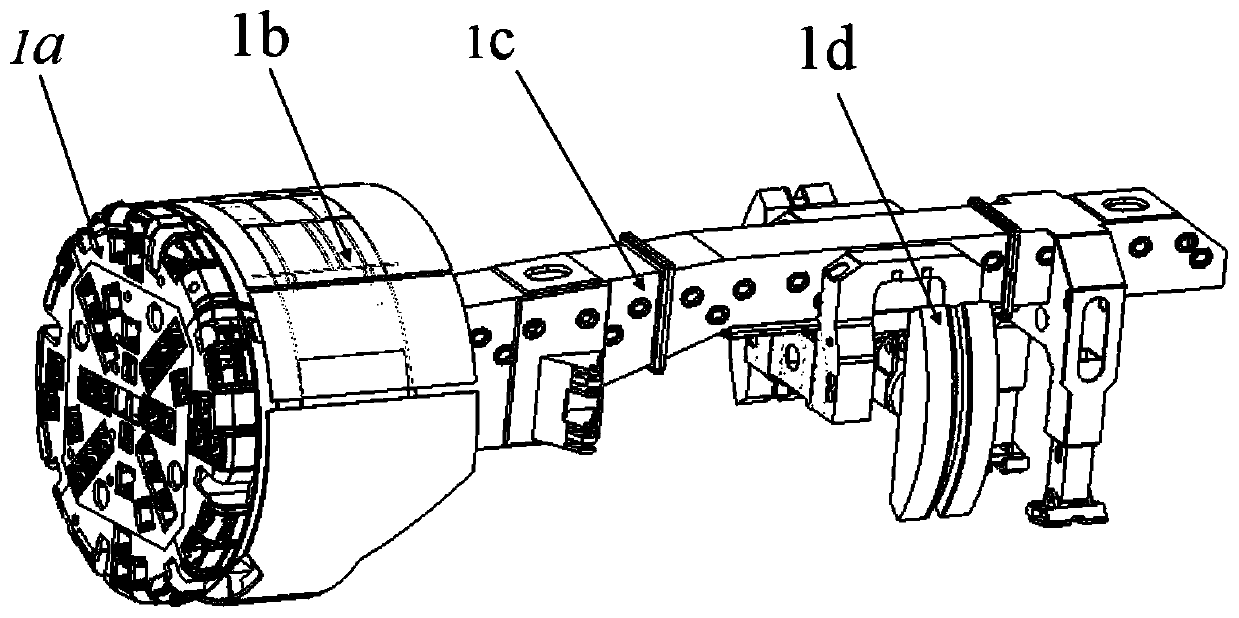

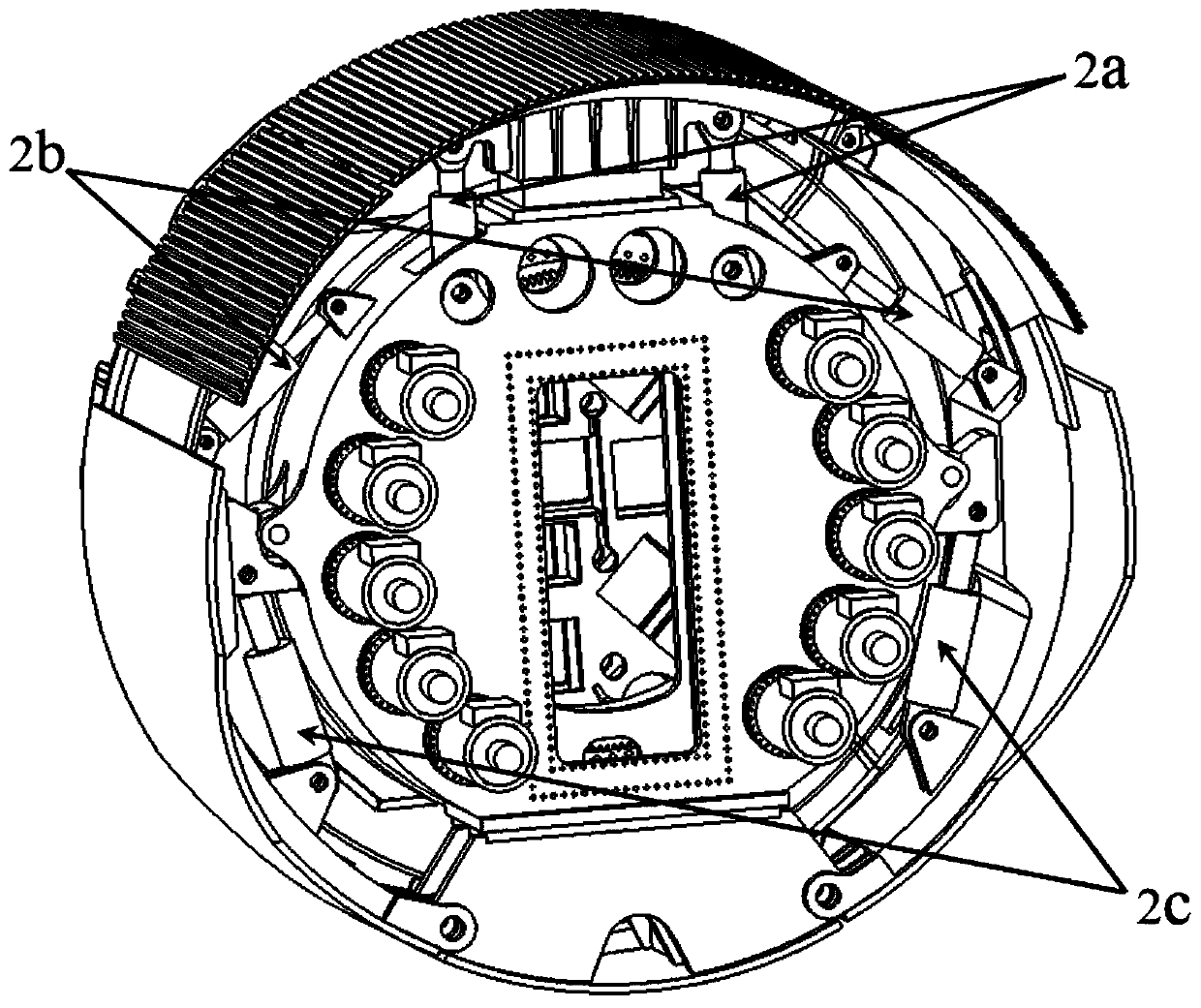

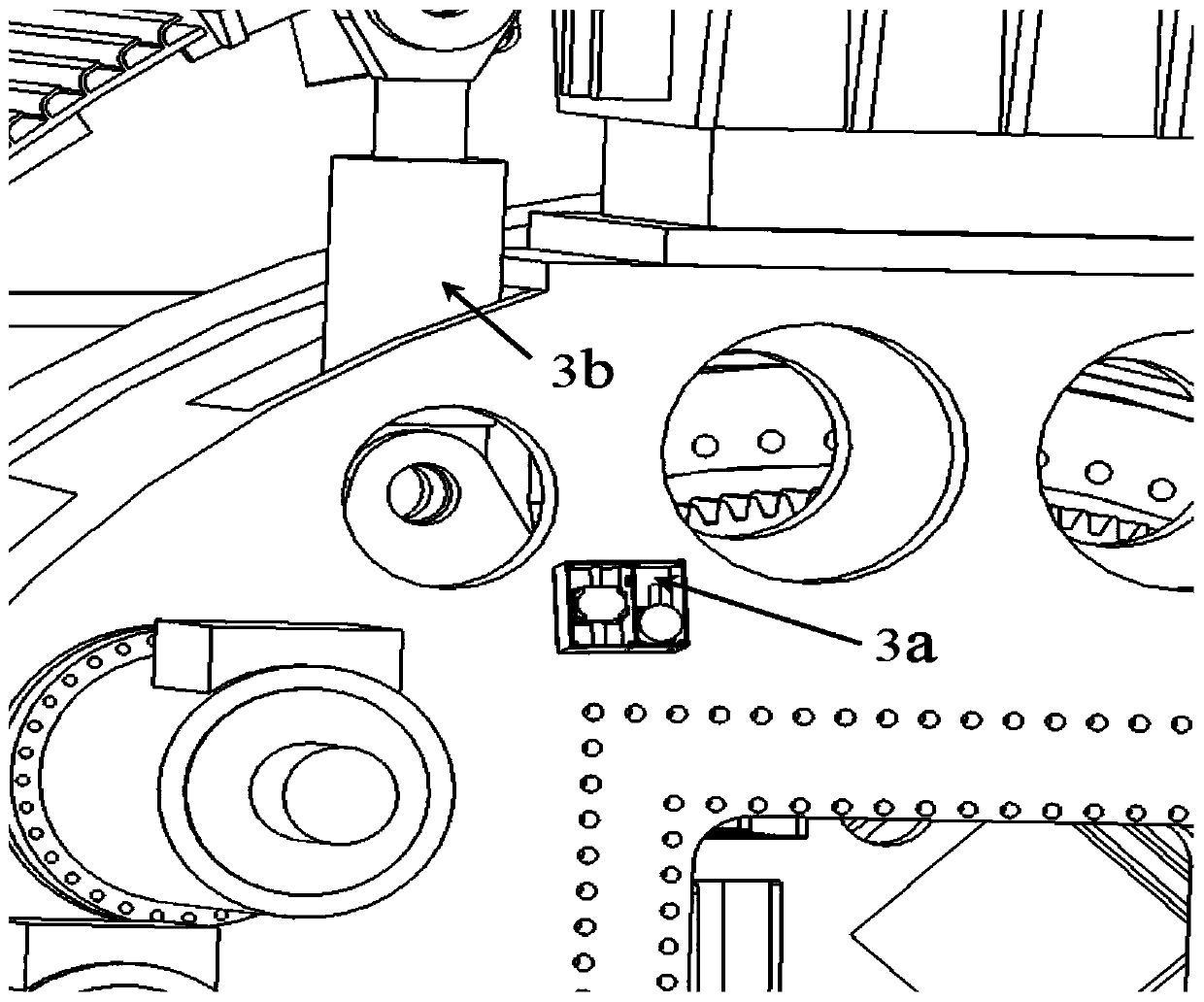

[0039] A method for monitoring the vibration at the joint of the cutter head support cylinder of a full-section rock excavation machine. The monitoring system for the vibration at the joint of the cutter support cylinder of the full-section rock excavation machine includes a sensor for measuring vibration and a wireless signal receiving device. The wireless gateway, the computer displaying the measurement data, the arrangement method of measuring points at the connection point of the cutter head support cylinder and the indirect prediction model; the vibration state during the operation of the corresponding position is monitored through the sensors arranged in the connection area of the cutter head support cylinder, and at the same time based on the wireless network The protocol accepts the transmission o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com