Power inspection robot control system and method based on wide-narrow heterogeneous communication technology

A communication technology and power inspection technology, which is applied in the field of power inspection robot control system based on wide-narrow heterogeneous communication technology, can solve the problems of reducing battery capacity, reducing the weight of the inspection robot, and extending the effective cruising range of the battery. , to achieve the effect of reducing the demand for battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

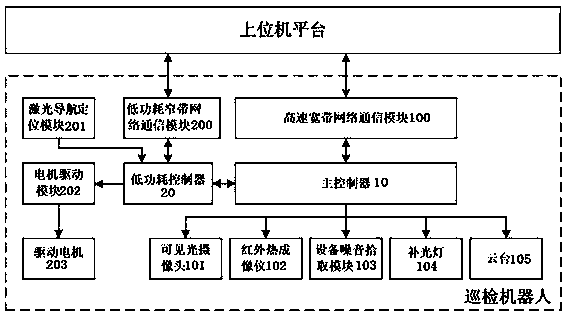

[0041] Such as figure 1 As shown, the power inspection robot control system based on wide-narrow heterogeneous communication technology includes a visible light camera 101, an infrared thermal imager 102, a device noise pickup module 103, a fill light 104, a pan / tilt 105, a laser navigation and positioning module 201, and a motor A drive module 202 and a drive motor 203; the motor drive module 202 is connected to the drive motor 203 for controlling the operation of the drive motor 203;

[0042] It also includes a main controller 10, a low-power controller 20, a high-speed broadband network communication module 100 and a low-power narrowband network communication module 200;

[0043] The main controller 10 is connected to the high-speed broadband network communication module 100, the visible light camera 101, the infrared thermal imager 102, the equipment noise pickup module 103, the fill light 104, and the cloud platform 105 respectively; Realize the data interaction with the...

Embodiment 2

[0052] Such as figure 1 As shown, the power inspection robot control system based on wide-narrow heterogeneous communication technology includes a visible light camera 101, an infrared thermal imager 102, a device noise pickup module 103, a fill light 104, a pan / tilt 105, a laser navigation and positioning module 201, and a motor A drive module 202 and a drive motor 203; the motor drive module 202 is connected to the drive motor 203 for controlling the operation of the drive motor 203;

[0053] It also includes a main controller 10, a low-power controller 20, a high-speed broadband network communication module 100 and a low-power narrowband network communication module 200;

[0054] The main controller 10 is connected to the high-speed broadband network communication module 100, the visible light camera 101, the infrared thermal imager 102, the equipment noise pickup module 103, the fill light 104, and the cloud platform 105 respectively; Realize the data interaction with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com