Method for preparing silicoaluminophosphate molecular sieve, silicoaluminophosphate molecular sieve and methanol-to-olefin method

A technology of silicoaluminophosphate and molecular sieve, which is applied in the field of catalysis, can solve the problems of large sewage discharge, low molecular sieve yield, and reduce water consumption, and achieve the effects of reducing discharge, easy storage, and reducing preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

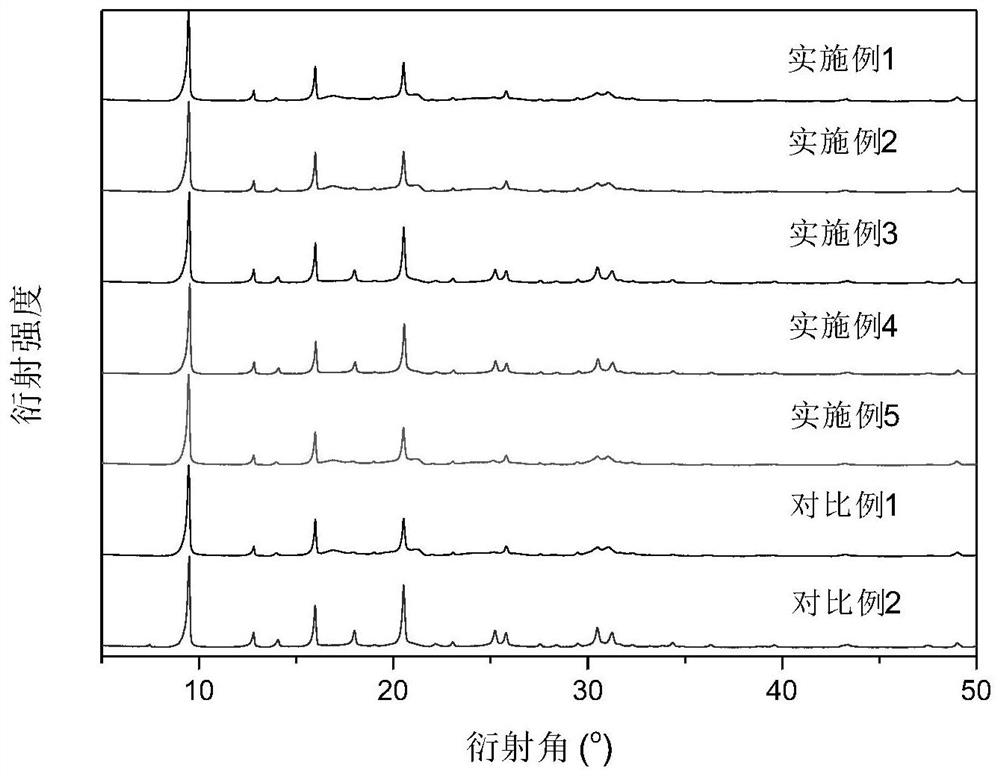

Examples

Embodiment 1

[0052] 1) Add 7.25g of pseudo-boehmite into 9.89g of deionized water, and after stirring evenly, add 5.41g of phosphoric acid (85%) and 5.63g of silica sol dropwise, and continue to stir for 1h. molar ratio to Al 2 o 3 :P 2 o 5 : SiO 2 :H 2 O=1:0.5:0.6:20. The mixture was dried overnight in an oven at 80°C.

[0053] 2) Grinding the dried silicon phosphorus aluminum dry rubber to obtain silicon phosphorus aluminum dry rubber powder. The obtained silicon phosphorus aluminum dry rubber powder was mixed with 3.73 g of phosphoric acid and 20.03 g of deionized water, and activated at 60° C. for 4 hours.

[0054] 3) Cool the treated mixed solution to room temperature, add 10.00 g of triethylamine, stir for 1 h, then transfer to a hydrothermal crystallization kettle for hydrothermal crystallization at 190° C. for 24 h. The obtained product was centrifugally washed with deionized water, filtered and dried, and then calcined at 550° C. for 8 hours in an air atmosphere to obtain ...

Embodiment 2

[0057] 1) Add 7.25g of pseudo-boehmite to 15.60g of deionized water, and after stirring evenly, add 10.82g of phosphoric acid (85%) and 4.69g of silica sol dropwise, and continue to stir for 1 hour, and each component material in the obtained mixture molar ratio to Al 2 o 3 :P 2 o 5 : SiO 2 :H 2 O=1:1:0.5:27. The mixture was dried overnight in an oven at 60°C.

[0058] 2) Grinding the dried silicon phosphorus aluminum dry rubber to obtain silicon phosphorus aluminum dry rubber powder. The obtained silicon phosphorus aluminum dry rubber powder was mixed with 1.12 g of phosphoric acid and 15.70 g of deionized water, and activated at 80° C. for 4 hours.

[0059] 3) Cool the treated mixed solution to room temperature, add 13.85 g of triethylamine, stir for 1 h, then transfer to a hydrothermal crystallization kettle for hydrothermal crystallization at 200° C. for 24 h. The obtained product was centrifugally washed with deionized water, filtered and dried, and then calcined ...

Embodiment 3

[0062] 1) Mix and stir 9.58g of aluminum isopropoxide, 13.38g of phosphoric acid (85%) and 13.25g of deionized water respectively. After stirring evenly, add 5.63g of silica sol dropwise, and continue stirring for 1 hour. molar ratio to Al 2 o 3 :P 2 o 5 : SiO 2 :H 2 O=1:1.2:0.6:23. The mixture was dried overnight in an oven at 60°C.

[0063] 2) Grinding the dried silicon phosphorus aluminum dry rubber to obtain silicon phosphorus aluminum dry rubber powder. The obtained silicon phosphorus aluminum dry rubber powder was mixed with 2.46 g of phosphoric acid and 18.19 g of deionized water, and activated at 80° C. for 4 hours.

[0064] 3) Cool the treated mixed solution to room temperature, add 11.25 g of triethylamine and 1.55 g of diethylamine, stir for 1 hour, then transfer to a hydrothermal crystallization kettle for hydrothermal crystallization at 200° C. for 24 hours. The obtained product was centrifugally washed with deionized water, filtered and dried, and then ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com