Construction method of bridge prestressed intelligent tension grouting system

An intelligent tensioning and prestressing technology, used in bridges, bridge construction, bridge materials, etc., can solve the problems of increased construction costs, increased vacuum equipment and vacuum steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

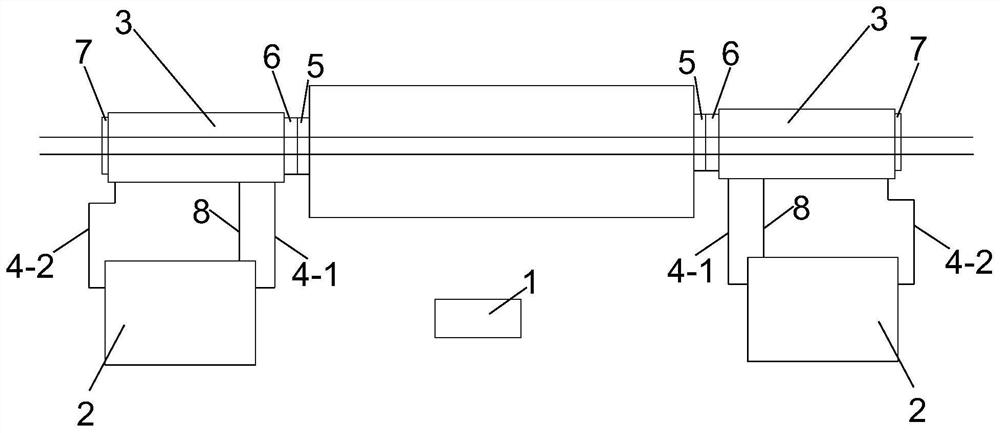

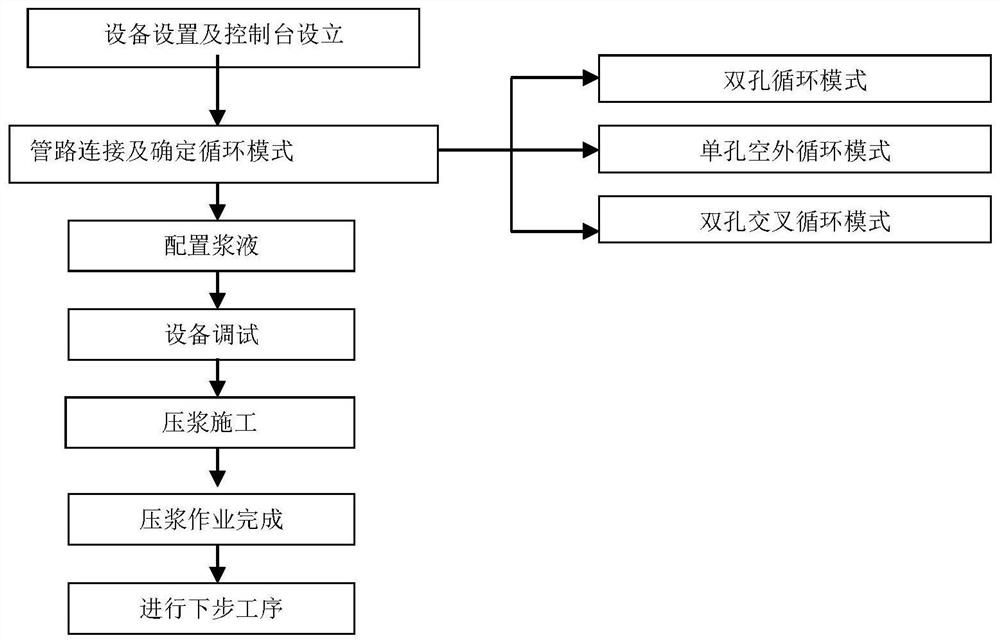

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1 Pre-grouting agent performance test

[0066] Select a transparent plastic pipe with a length of 100m and an inner diameter of 10cm as the prestressed pipe for testing. The prestressed tendons pass through the axial center of the transparent plastic pipe, and the two ends are fixed on the sealing plug of the transparent plastic pipe mouth. Continuously inject the pre-grouting agent into the transparent plastic tube through the grouting hole, the pre-grouting agent flows out from the grouting hole on the sealing plug at the other end of the transparent plastic tube, inject the pre-grouting agent in a cycle for 30 minutes, and open the seal at one end of the transparent plastic tube plug, discharge the pre-compression agent in the transparent plastic tube, and install the sealing plug. The pre-compacting agent consists of 200 kilograms of sodium edetate, 400 kilograms of sodium bicarbonate, 500 kilograms of trisodium phosphate, 900 kilograms of triethanolamine...

Embodiment 2

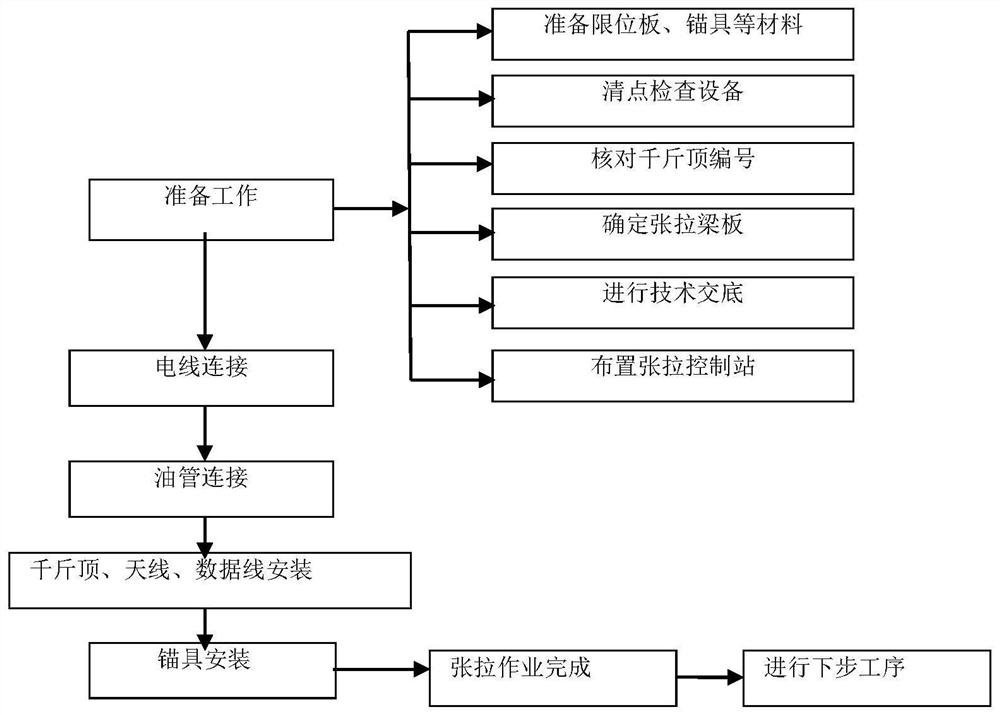

[0069] The construction method of bridge prestressed intelligent tension grouting system includes the following steps:

[0070] (1) Use the prestressed intelligent tensioning system for prestressed steel strand tensioning construction;

[0071] 1.1 Prepare the limit plate, anchorage, clip, computer (pre-installed WindowsXP operating system, self-contained wireless network adapter), three-phase cable, parasol, etc. that can be used with the tensioning system must be fully prepared.

[0072] 1.2. Check the equipment against the tensioning system list, and make sure that the equipment is in good condition and the accessories are complete.

[0073] 1.3. Check the serial number of the jack. Since the jacks are uniformly calibrated before leaving the factory, you must pay attention to the correct calibration formula when using them.

[0074] 1.4. Determine the beam and slab to be stretched.

[0075] 1.5. Conduct technical clarification and learn to be familiar with the system soft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com