Grouting reinforcement method for three-soft-coal-seam large-mining-height working face top slope

A three-soft coal seam, grouting reinforcement technology, applied in mining equipment, earth-moving drilling, wellbore lining and other directions, can solve the problems of the roof not forming a whole, the roof structure is loose, and the normal mining is difficult, etc., to achieve the effect of sealing holes Good, short response time, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A grouting reinforcement method for the roof of a working face with a large mining height in a three-soft coal seam, comprising the following steps:

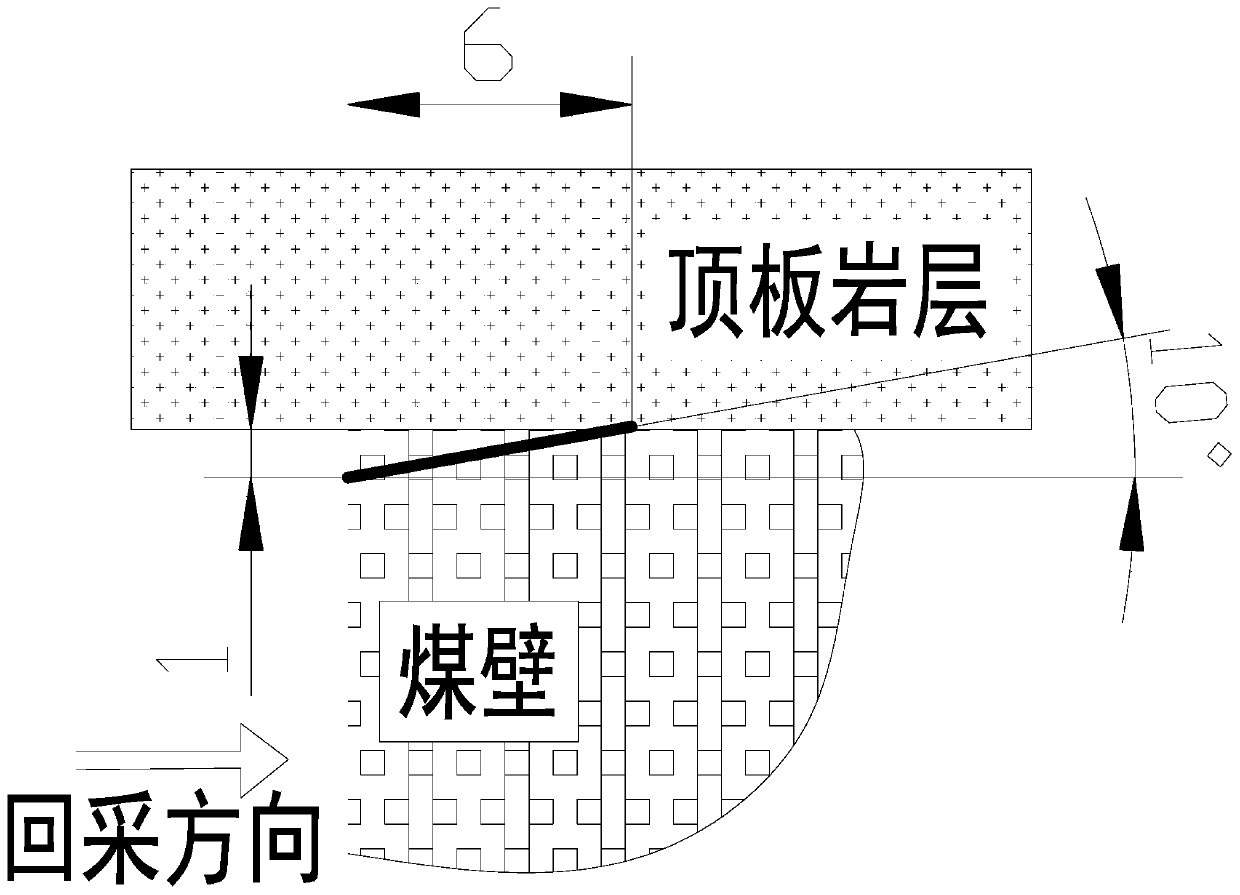

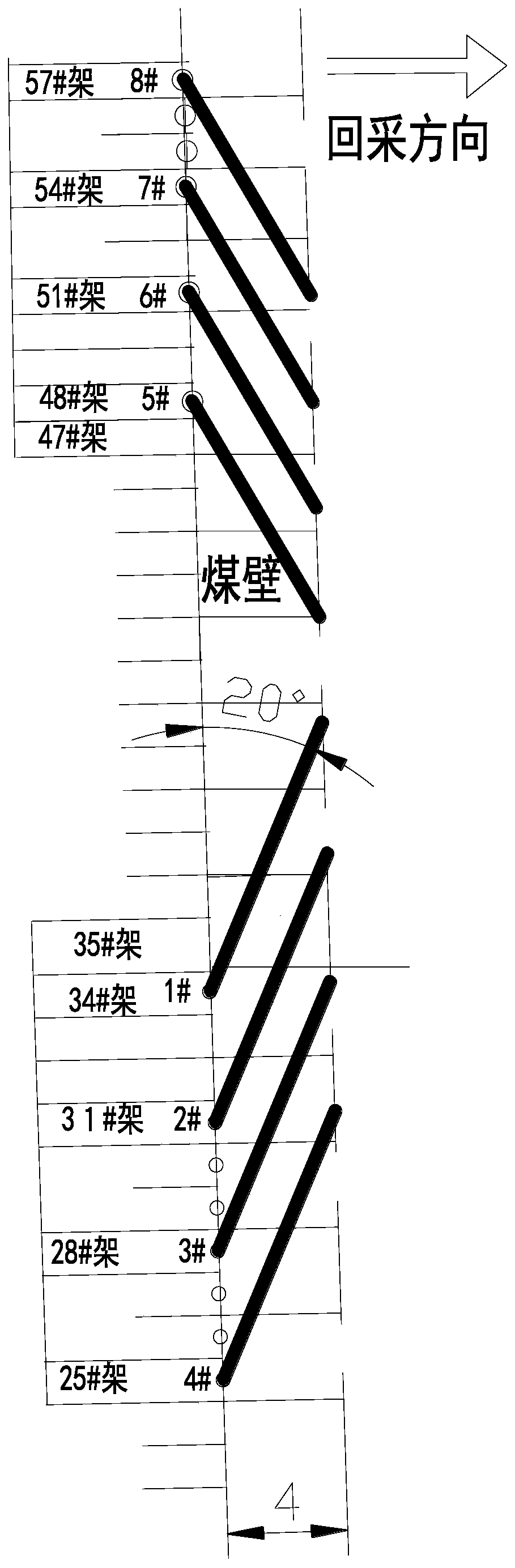

[0045] A. Drilling straight holes in the coal wall: firstly judge whether the top gang has the drilling conditions. figure 1 As shown, the drilling parameters are as follows: the hole is 1m away from the roof, the elevation angle is 10°, the end point of the hole is 6m away from the coal wall, the projection of the axis of the hole on the horizontal plane is perpendicular to the coal wall, the hole diameter is 42mm, and the corresponding branch of two adjacent holes There is 1 support frame between the frames;

[0046] B. Grouting of coal wall straight holes: After the coal wall drilling is completed, the reinforcement material is injected into the coal wall hole. In this embodiment, the reinforcement material is selected from the Mina mine filling material, which is commercially available, and the injection is stopped un...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is:

[0056] In step A, the hole is 1.2m away from the top plate, the elevation angle is 12°, the end point of the hole is 7m away from the coal wall, the hole diameter is 42mm, and there are 2 supporting frames between the supporting frames corresponding to two adjacent holes;

[0057] In step B, the sealing depth is 2.5m;

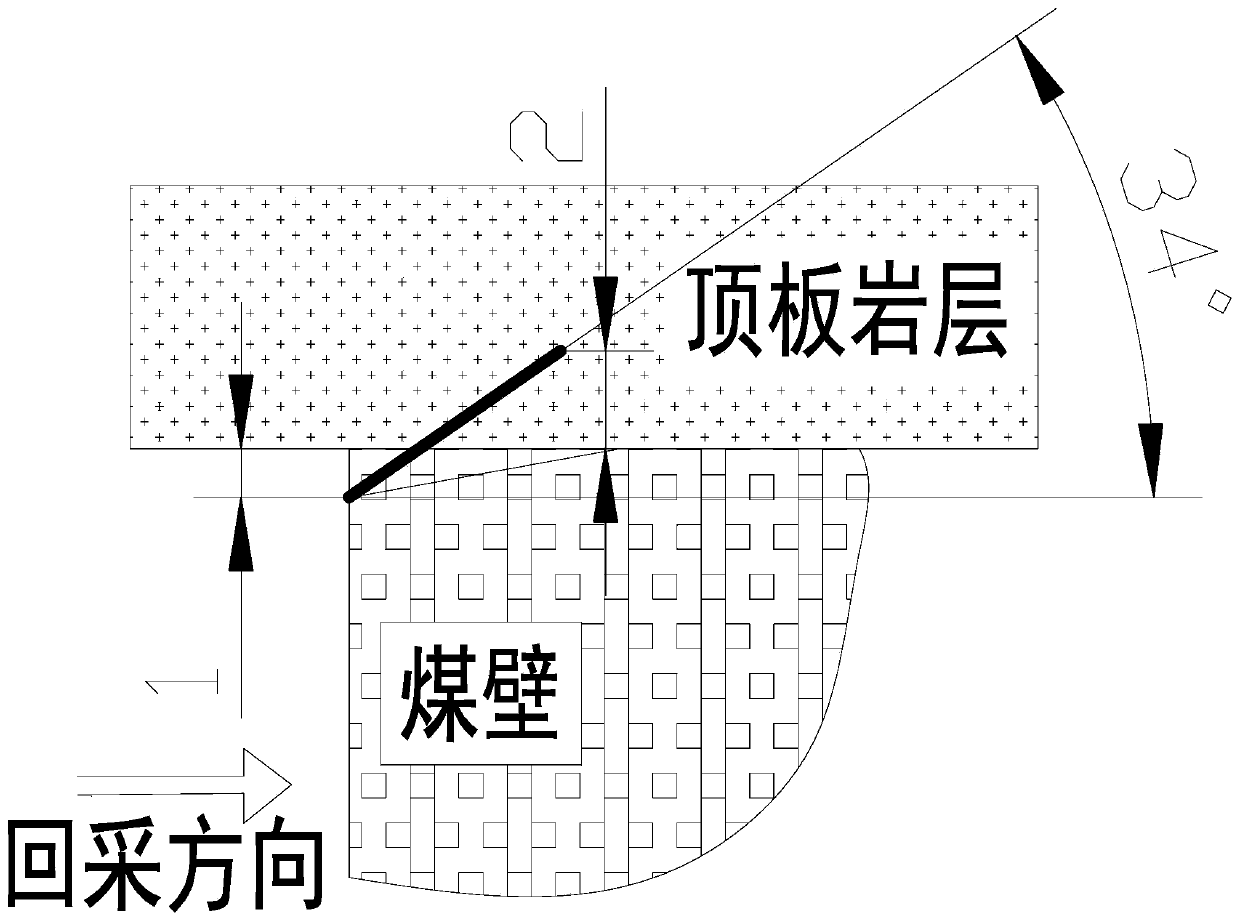

[0058] In step C, the hole is 1.2m away from the top plate, the elevation angle is 12°, the end point of the hole is 5m away from the coal wall, the angle between the projection of the axis of the hole on the horizontal plane and the coal wall is 30°, and the hole diameter is 42mm. There is 1 support frame between the support frames;

[0059] The sealing depth in step D is 2.5m;

[0060] In step E, the hole is 1.2m away from the top plate, the elevation angle is 40°, the end point of the hole is above the top plate and 2.3m away from the top plate, the hole diameter is 42mm, and there is one...

Embodiment 3

[0066] The difference between this embodiment and Embodiment 1 is:

[0067] In step A, the hole is 1.5m away from the top plate, the elevation angle is 15°, the end point of the hole is 8m away from the coal wall, the hole diameter is 42mm, and there are 3 supporting frames between the supporting frames corresponding to two adjacent holes;

[0068] The sealing depth in step B is 3m;

[0069] In step C, the hole is 1.5m away from the top plate, the elevation angle is 15°, the end point of the hole is 6m away from the coal wall, the angle between the projection of the axis of the hole on the horizontal plane and the coal wall is 35°, the hole diameter is 42mm, and the two adjacent holes correspond to There are 3 support frames between the support frames;

[0070] The sealing depth in step D is 2m;

[0071] In step E, the hole is 1.5m away from the top plate, the elevation angle is 57°, the end point of the hole is located above the top plate and 2.5m away from the top plate, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com