Cylindrical roller bearing roller vertical inclination and swinging state measuring method

A technology for cylindrical roller bearings and measurement methods, which is applied in the direction of roller bearings, bearings, bearing assembly, etc., and can solve the problems of inaccurate distribution of contact force between rollers and raceways, inaccurate identification of working conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

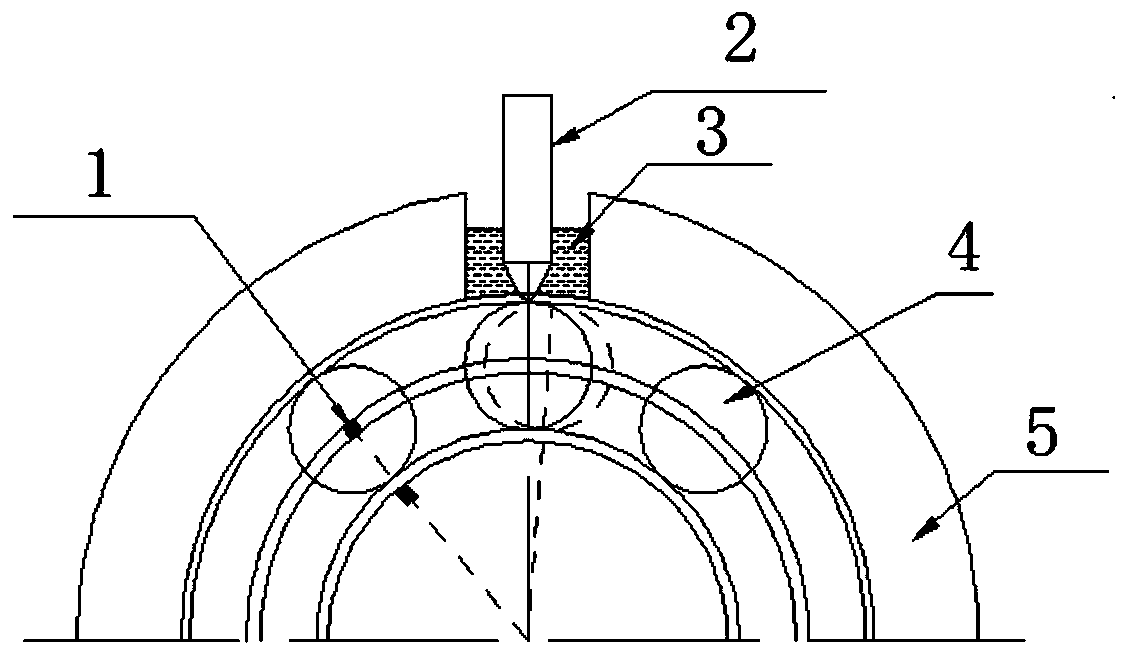

[0045] see figure 1 , is a schematic diagram of the rollers of the cylindrical roller bearing tilting up and down in this example of the present invention, and the rollers of the rolling bearing will tilt to a certain extent during the actual working process.

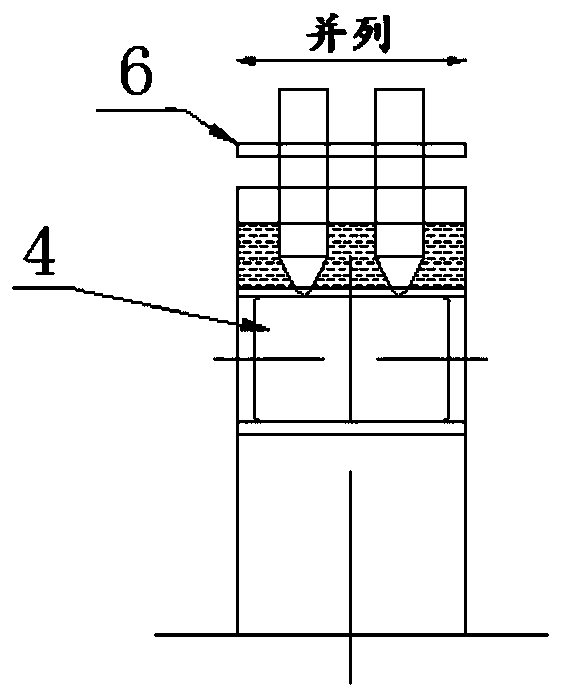

[0046] see figure 2 with image 3 , is a schematic diagram of the installation of the ultrasonic sensor in this example of the present invention, wherein, 1 is a reflective sheet, 2 is an ultrasonic sensor, 3 is water, 4 is a cylindrical roller, 5 is a bearing seat, and 6 is a bracket. Under good coupling conditions, two ultrasonic sensors are installed side by side along the roller length direction just above the outer ring of the bearing. Using double probes to measure in parallel, based on the equivalent stiffness method, the oil film thickness h, ultrasonic signal reflectivity R and incident ultrasonic frequency f can be simplified as a function of formula (1). Through the high-frequency focused ultrasonic senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com