Microcurrent detecting circuit

A detection circuit and micro-current technology, applied in the field of micro-current, can solve problems such as low operating frequency, complicated operation, and large signal-to-noise ratio, and achieve the effect of improving response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

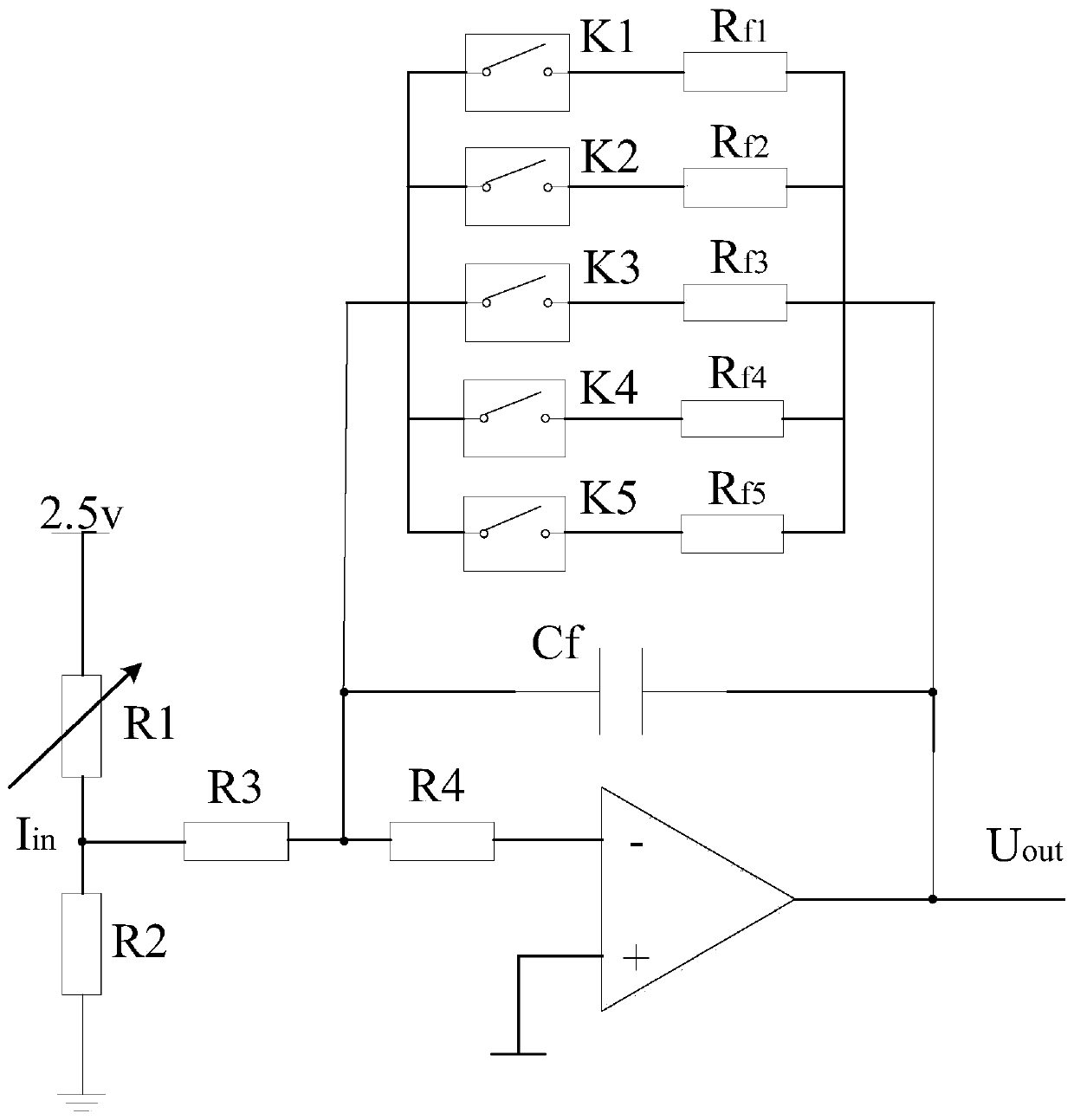

[0038] When measuring micro current, use a high resistance to provide the required fA-level current, and use a high resistance as a feedback resistor to suppress the signal-to-noise ratio and achieve the required stable voltage. Adding a feedback capacitor can offset the influence of the input capacitor and improve the response time , By adding protection resistors, the circuit will not be damaged by accidental overvoltage, adding five feedback branches, and controlling the on-off of each feedback branch relay to achieve the detection of micro-currents of various magnitudes. Through the description of the above circuit, the circuit can output a stable fA level current.

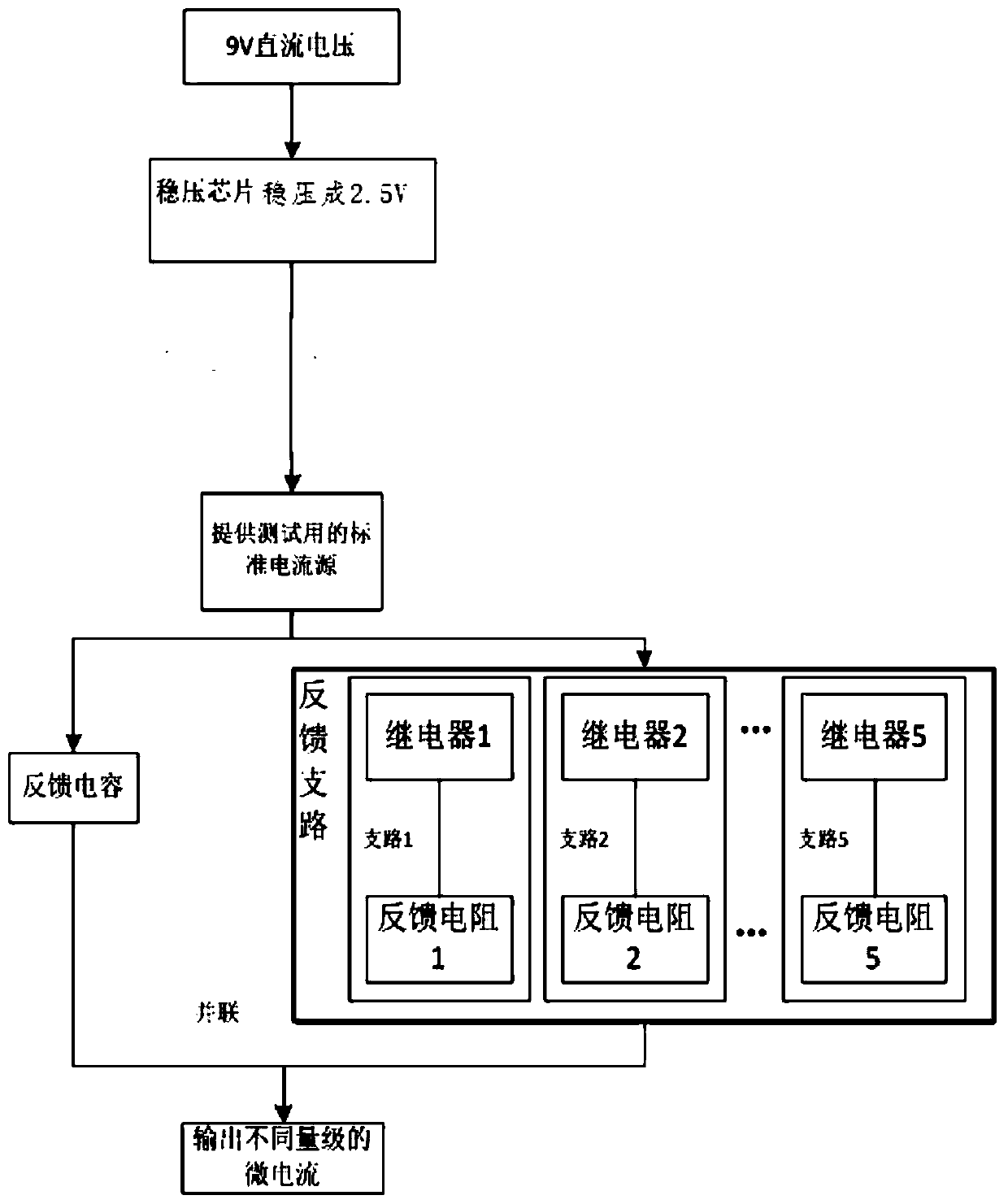

[0039] refer to figure 1 , showing a structural block diagram of an embodiment of microcurrent detection, specifically including the following components:

[0040] Regulator circuit regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com