Beer picking machine applied to beer gun and novel beer gun

A technology of wine fetcher and wine cannon, which is applied in the direction of liquid distribution, packaging, distribution devices, etc. It can solve the problems of affecting the quality of beer, the beer is easy to be polluted, and the taste of beer cannot be achieved, so as to save the operation time of changing wine and avoid The effect of health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

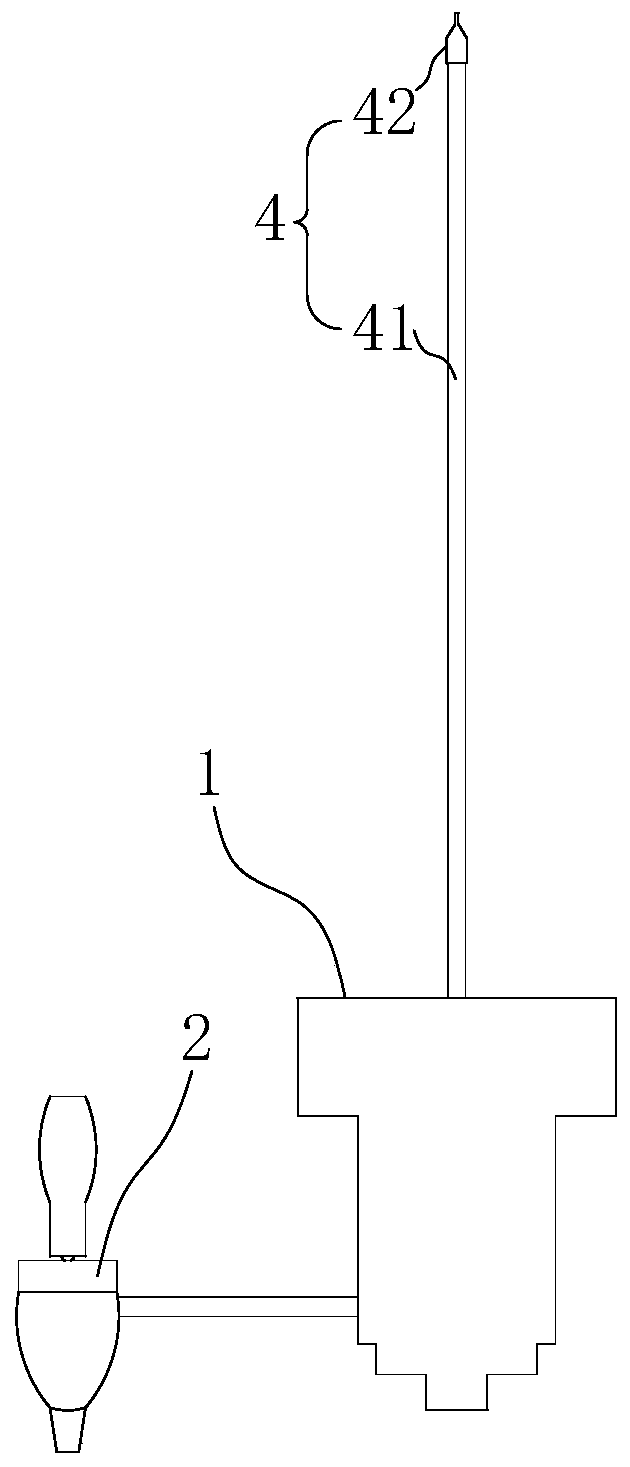

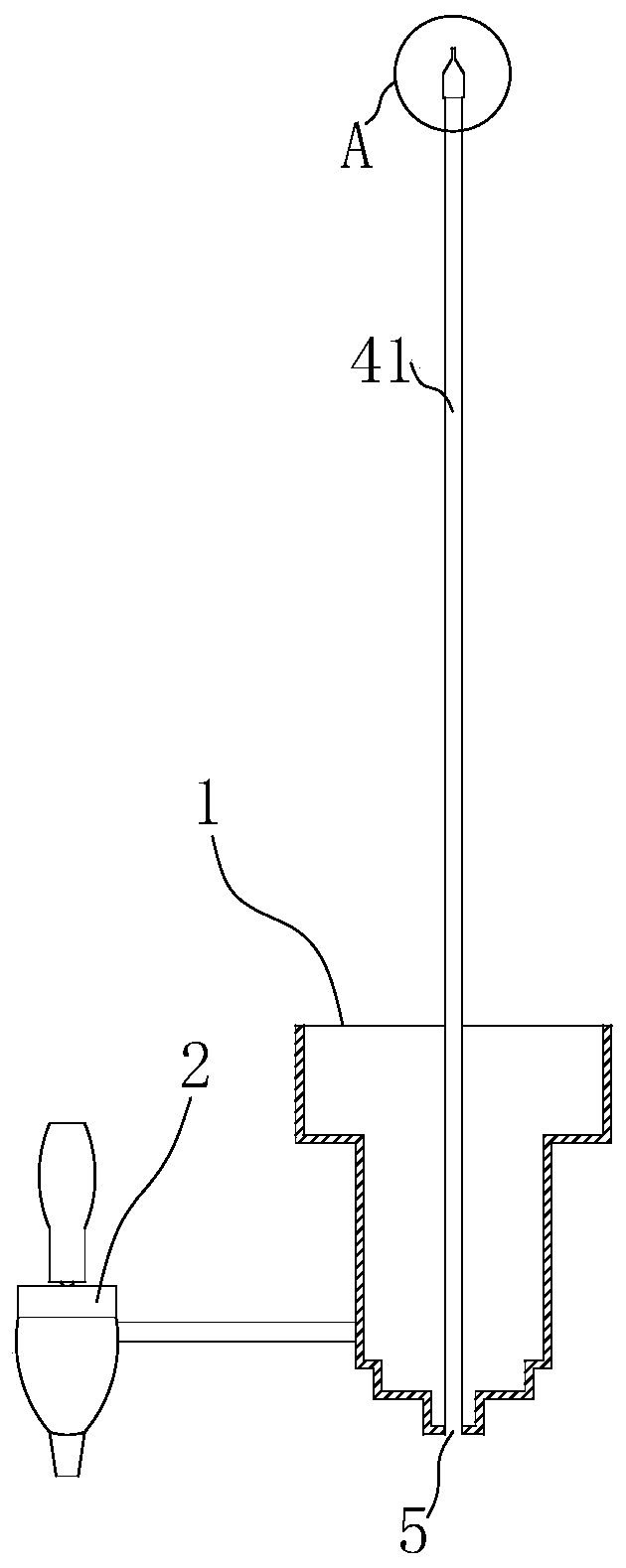

[0032] to combine Figure 1 to Figure 5 , a kind of beer wine cannon wine fetching device, comprises the seal 1 that is movably connected with the wine container, and the wine outlet valve 2 is housed on the seal 1. When the sealing member 1 is assembled with the wine container, the sealing member 1 will close the opening of the wine container, and the sealing member 1 is provided with a one-way air-guiding component 4, which allows the gas to conduct in one direction. The one-way air guide part 4 is composed of an air guide tube 41 and a one-way valve 42. The sealing member 1 is provided with a through hole 5. One end of the air guide tube 41 is inserted into the through hole 5, and the other end is connected with a one-way valve. Valve 42.

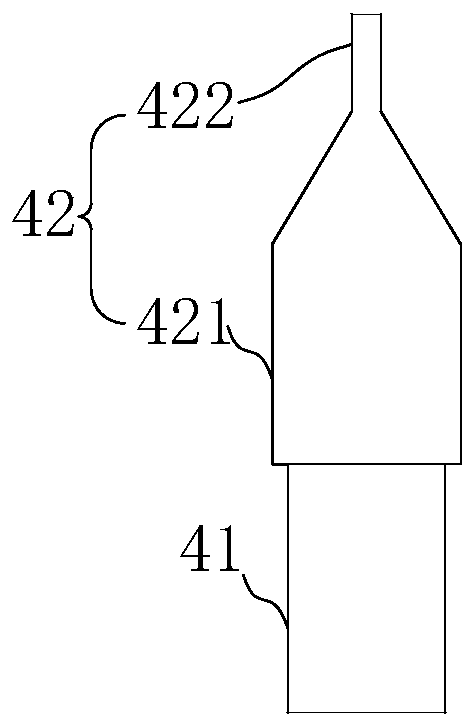

[0033] The one-way valve 42 is made of elastic material. The one-way valve 42 is composed of a sleeve part 421 and a clamping part 422. The sleeve part 421 is sleeved on the airway tube 41. 422 is formed with an air guide slit 6 penetr...

Embodiment 2

[0036] to combine Figure 1 to Figure 6 , a new type of beer wine cannon, including a wine container 9, a seal 1 and a support seat 8, the seal 1 is assembled under the wine container 9, and the seal 1 will hold Wine container 9 openings are closed. The support seat 8 is movably connected with the sealing member 1 , and the support seat 8 props up the wine container 9 through the sealing member 1 .

[0037] The sealing member 1 is provided with a one-way air-guiding component 4, and the one-way air-guiding component 4 conducts one-way from the outside to the wine container 9. The one-way air guide part 4 is composed of an air guide tube 41 and a one-way valve 42. A through hole 5 is opened on the sealing member 1. The lower end of the air guide tube 41 is inserted into the through hole 5, and the air guide tube 41 extends upward to The top of the wine container 9 is connected with a one-way valve 42 at the upper end of the air duct 41 .

[0038] The one-way valve 42 is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com