Thermal transfer printing coating

A thermal transfer printing and coating technology, which is applied in the direction of polyester coating, powder coating, coating, etc., can solve the problems of high price and high cost, and achieve the effect of low cost and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

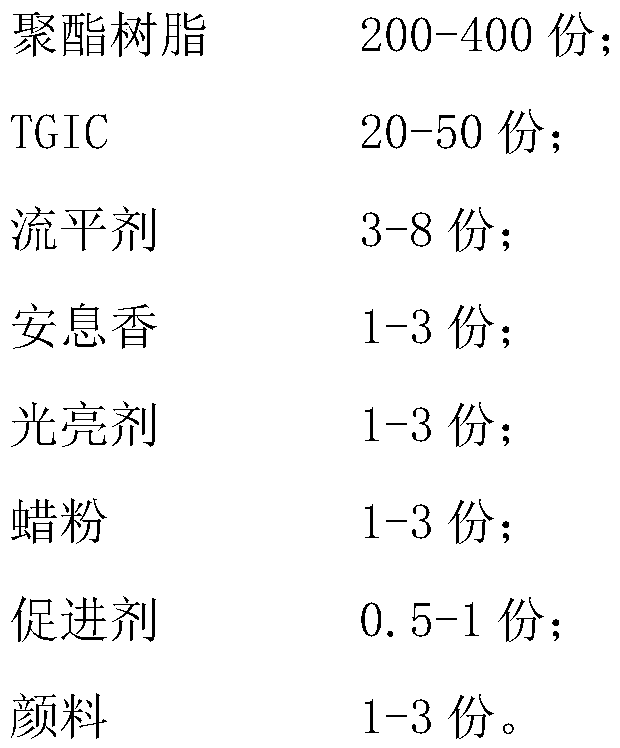

[0011] Thermal transfer powder coating, which comprises the following components by mass parts:

[0012]

[0013] Among them, the acid value of polyester resin is 42mgKOH g -1 .

[0014] The preparation method of the thermal transfer paint, the polyester resin, TGIC, leveling agent, benzoin, brightener, wax powder, accelerator pigment in the above ratio are pre-mixed to 200°, melted and extruded, cooled and crushed, crushed, Curing for 10 minutes to prepare a thermal transfer base powder sample, and then heat transfer the prepared sample with a thermal transfer heat press machine to obtain a thermal transfer sample.

Embodiment 2

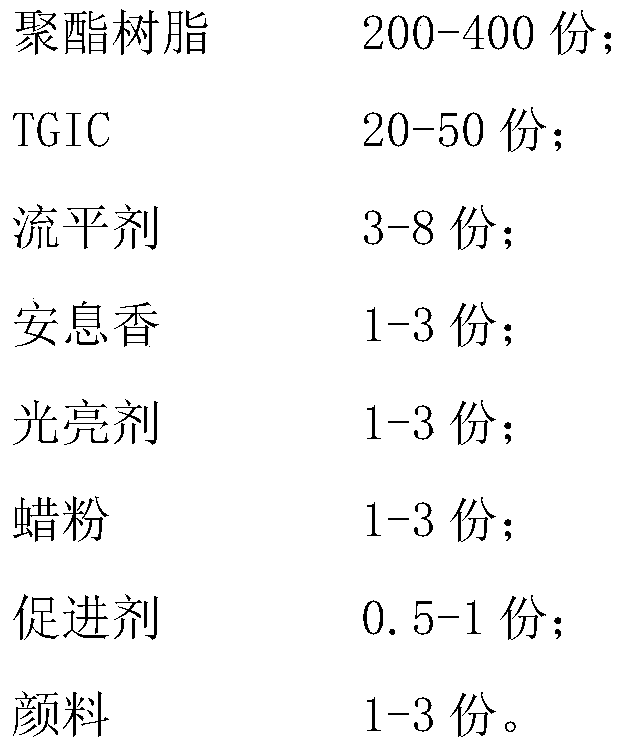

[0016] Thermal transfer powder coating, which comprises the following components by mass parts:

[0017]

[0018] Among them, the acid value of polyester resin is 40mgKOH g -1 .

[0019] The preparation method of the thermal transfer paint, the polyester resin, TGIC, leveling agent, benzoin, brightener, wax powder, accelerator pigment in the above ratio are pre-mixed to 200°, melted and extruded, cooled and crushed, crushed, Curing for 10 minutes to prepare a thermal transfer base powder sample, and then heat transfer the prepared sample with a thermal transfer heat press machine to obtain a thermal transfer sample.

[0020] Embodiment two

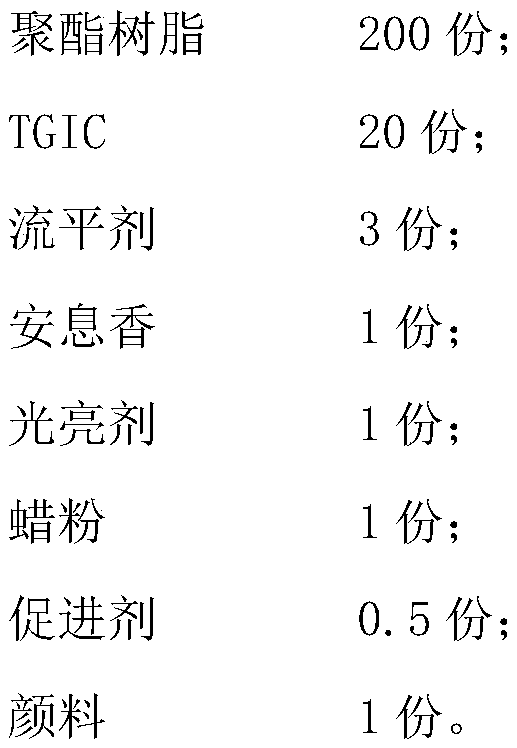

[0021] Thermal transfer powder coating, which comprises the following components by mass parts:

[0022]

[0023] Among them, the acid value of polyester resin is 45mgKOH g -1 .

[0024] The preparation method of the thermal transfer paint, the polyester resin, TGIC, leveling agent, benzoin, brightener, wax powder, accelerator p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com