Array substrate, display device and preparation method of array substrate

An array substrate and dielectric layer technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as abnormal electrical characteristics, SD metal wire breakage, dielectric layer breakage, etc., to improve ductility and flatness, prevent break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

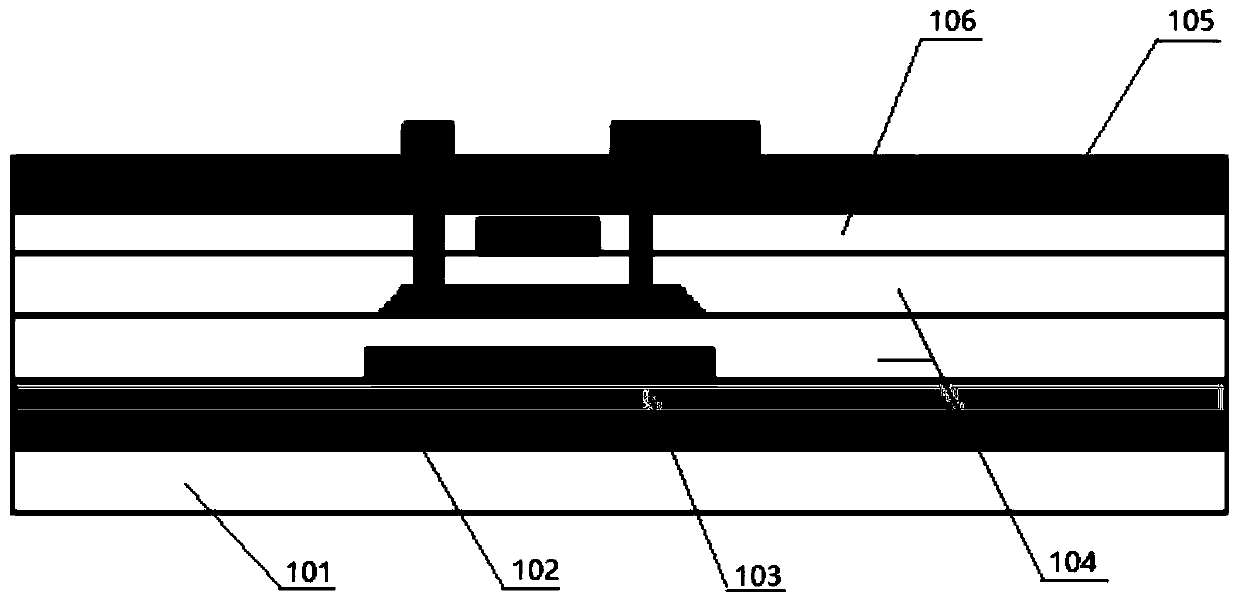

[0040] refer to figure 1 , shows one of the schematic diagrams of an array substrate of the present invention.

[0041] An embodiment of the present invention provides an array substrate, including a substrate 101, a PI layer 102, a protective layer 103, a thin film transistor layer 104, and a dielectric layer stacked on the substrate 101; wherein, the PI layer 102 is pasted attached to the substrate 101;

[0042] The dielectric layer includes an inorganic dielectric layer 106 and an organic dielectric layer 105 which are stacked.

[0043] In the embodiment of the present invention, the array substrate may be used in a flexible display.

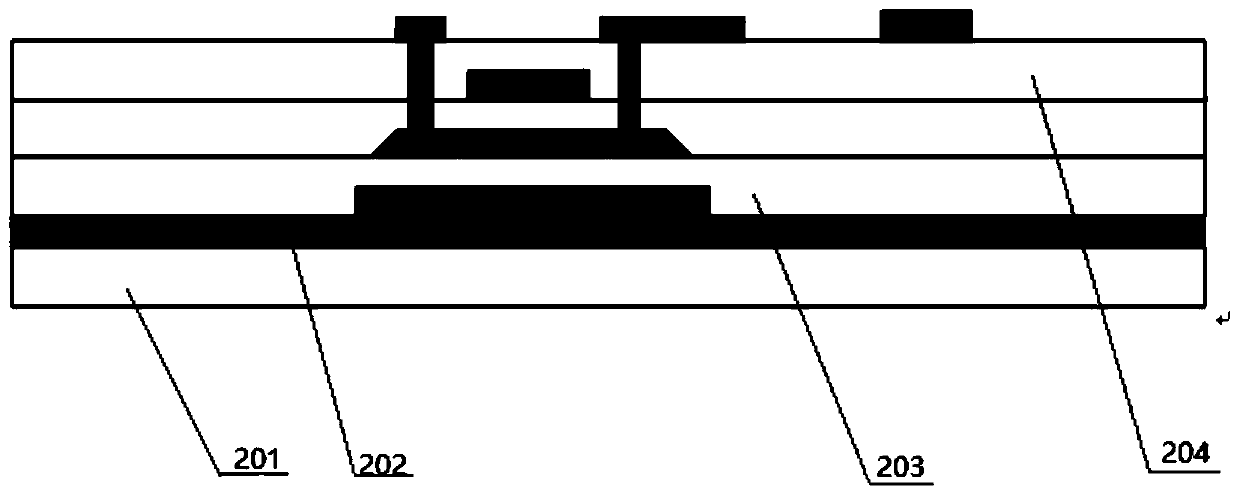

[0044] Such as figure 2 The partial schematic view of the traditional array substrate shown includes: a substrate 201, a PI layer 202, a thin film transistor layer 203 and a dielectric layer 204. When performing a curved LCD (liquid crystal display) process, the PI layer 202 of the first transistor is arranged on On the substrate 201, af...

Embodiment 2

[0054] An embodiment of the present invention also provides a display device. The display device includes the above-mentioned array substrate. The array substrate includes a substrate, and a PI layer, a protective layer, a thin film transistor layer and a layer stacked on the substrate. Dielectric layer; wherein, the PI layer is attached on the substrate;

[0055] The medium layer includes an inorganic medium layer and an organic medium layer stacked.

[0056] The material of the protective layer includes SiOx, and the thickness of the protective layer includes 0.2-0.3 μm.

[0057] The material of the inorganic medium layer includes at least SiNx, and the thickness range of the inorganic medium layer includes 0.1-0.3 μm.

[0058] The material of the organic medium layer includes polysilsesquioxane photosensitive resin, and the thickness range of the organic medium layer includes 0.8-1.2 μm.

[0059] In the embodiment of the present invention, the protective layer is used to ...

Embodiment 3

[0061] refer to Figure 6 , shows a flow chart of a method for preparing a film layer structure in an embodiment of the present invention.

[0062] Step 601, providing a substrate.

[0063] In this embodiment, the substrate is a glass substrate.

[0064] Step 602, attaching a PI layer on the substrate.

[0065] In this embodiment, the PI layer is made of a polyimide material layer, and the main chain of the PI molecule has a stable imide aromatic heterocyclic structure, and its stretchability can reach 200 MPa.

[0066] Step 603, forming a protection layer on the PI layer.

[0067] In the embodiment of the present invention, the PI layer that has been fabricated before is attached to the substrate, and a protective layer is formed on the PI layer by CVD. The material of the protective layer is SiOx, and a thickness of 0.2-0.3μm SiOx protective layer. The CVD (Chemical Vapor Deposition, chemical vapor deposition) method refers to introducing the vapor of the gaseous reacta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com