Flexible OLED device and preparation method thereof

A device and flexible technology, applied in the field of light-emitting display, can solve problems such as package structure failure and film layer fracture, and achieve the effect of increasing the contact surface area and reducing the risk of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of a flexible OLED device and its manufacturing method involved in the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments.

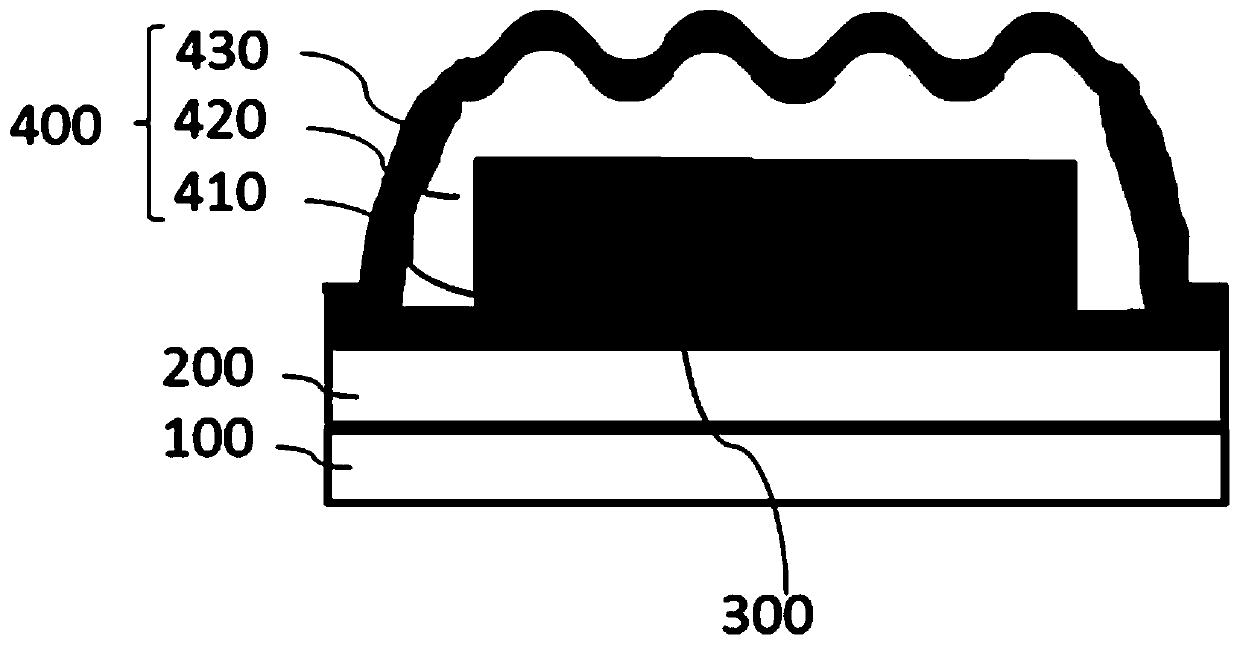

[0045] see figure 1 As shown, one embodiment of the present invention provides a flexible OLED device, which includes a substrate 100 , an array (Array) unit layer 200 , a light emitting device layer 300 and an encapsulation layer 400 arranged in sequence.

[0046] The array unit layer 200 includes a buffer layer, a TFT layer, a planarization layer, an anode, a pixel definition layer, and the like. The light emitting device layer 300 includes a hole injection / transport layer, a light emitting layer, an electron transport / injection layer, a cathode, and the like. The encapsulation layer 400 includes a first inorganic layer 410 , a first organic layer 420 and a second inorganic layer 430 . Wherein the contact surface between the first organic layer 420 and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap