Rectangular waveguide-microstrip power divider and rectangular waveguide matching load

A technology of power divider and rectangular waveguide, which is applied in the direction of waveguide devices, electrical components, connecting devices, etc., can solve the problem that the matching load of rectangular waveguide cannot meet the requirements of compact system, achieve simple and mature processing and assembly technology, and expand standing wave bandwidth , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

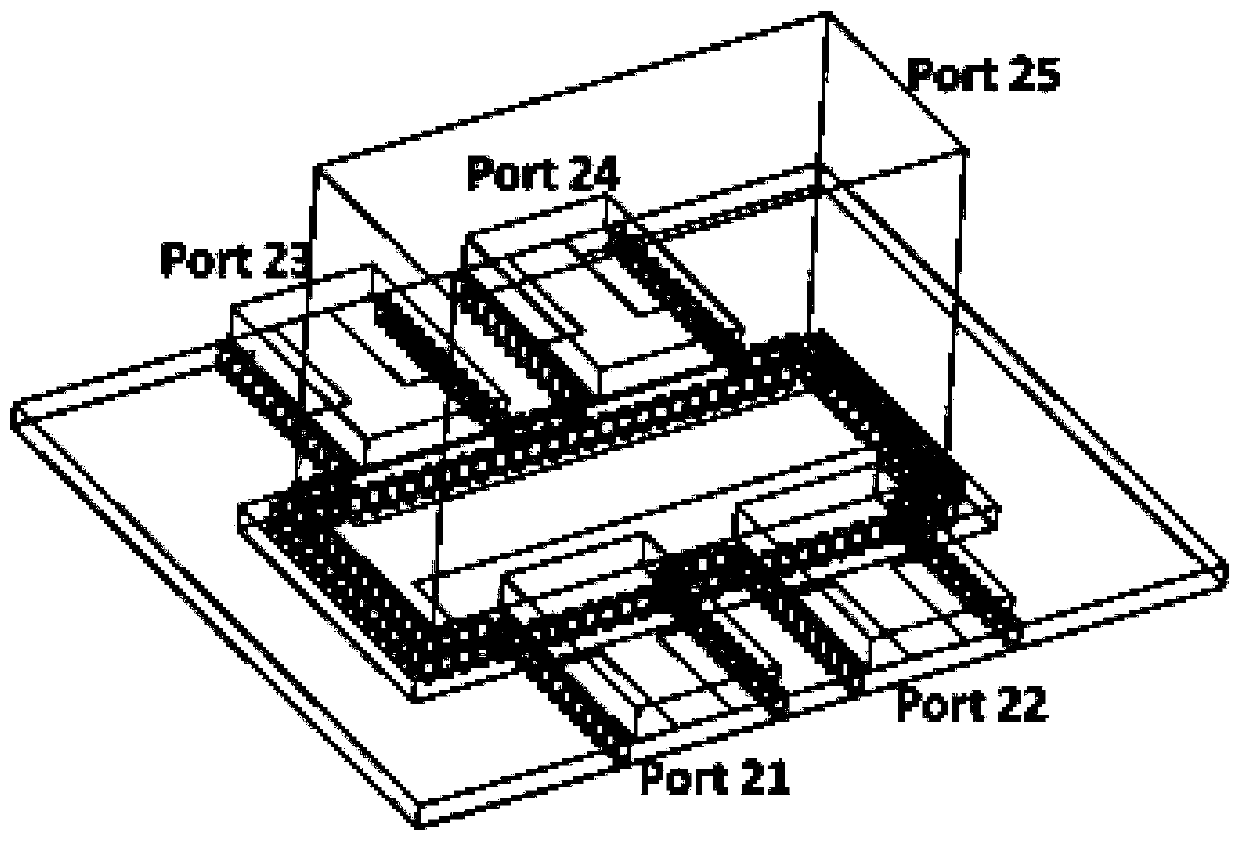

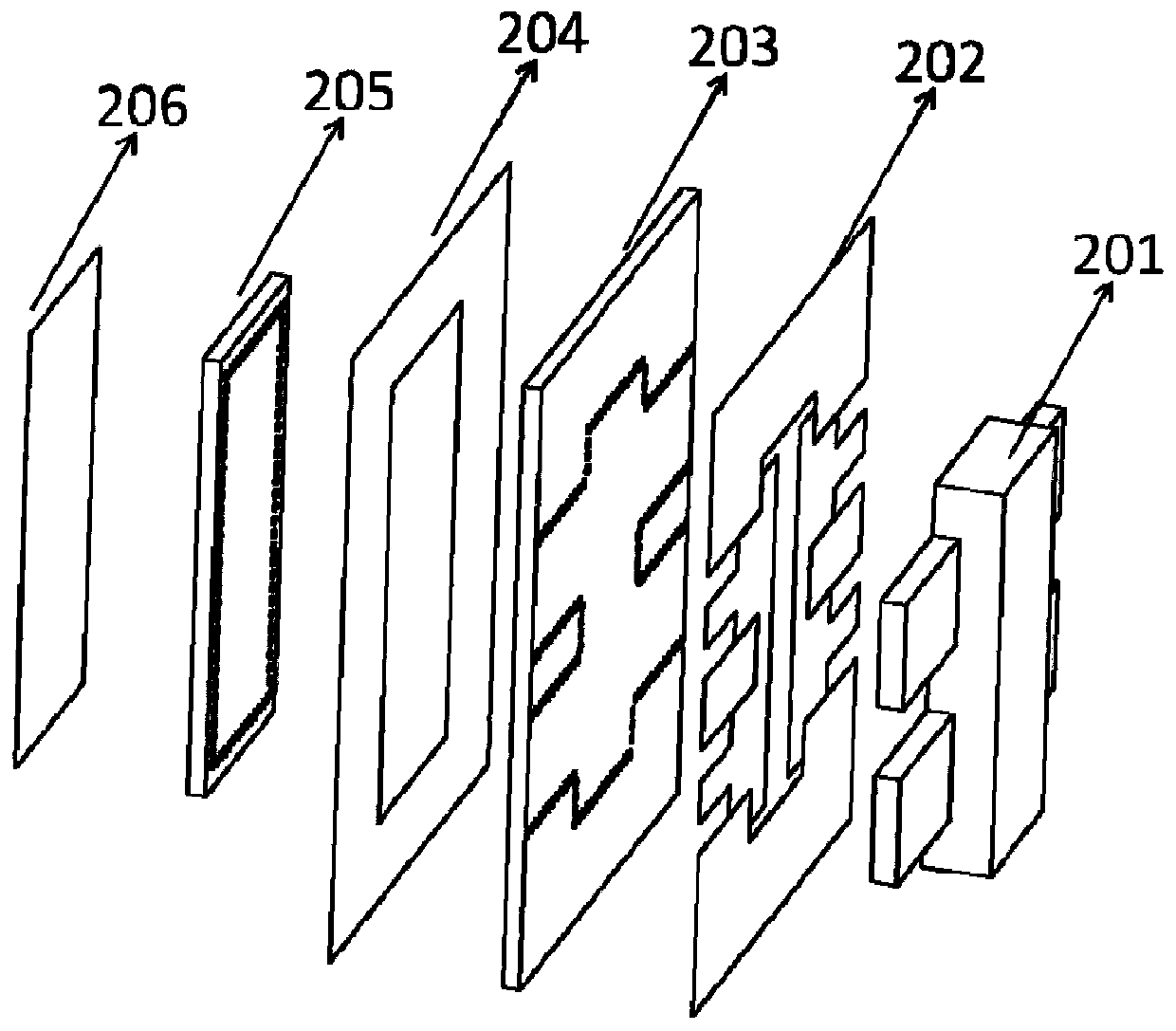

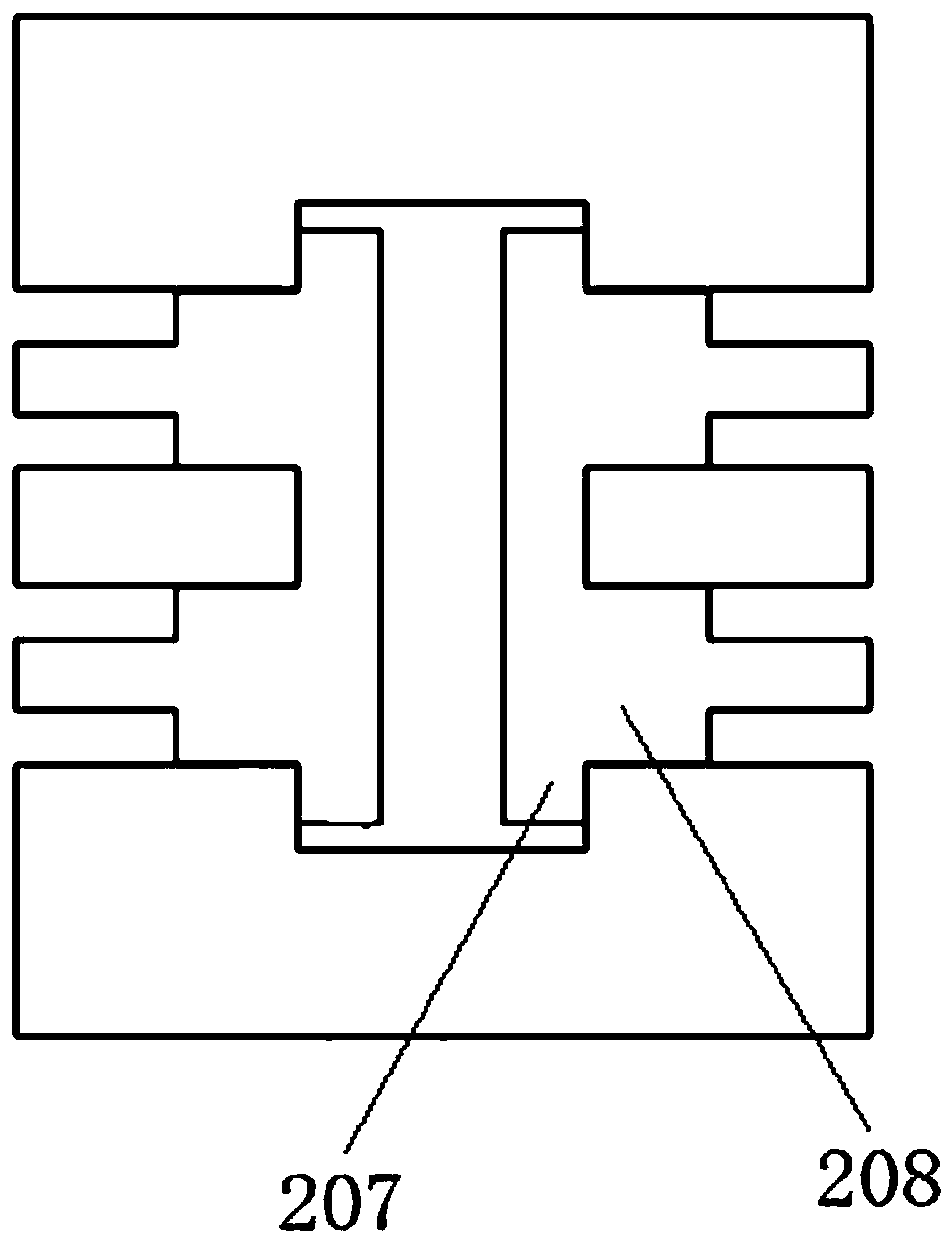

[0051] Such as figure 1 , figure 2 , image 3As shown, it is a rectangular waveguide-microstrip four-way power divider, which has a rectangular waveguide input port port25 and four microstrip output ports port 21-port 24; the compact waveguide-microstrip four-way power divider includes sequentially stacked The input rectangular waveguide 201 , the first metal layer 202 , the first dielectric layer 203 , the second metal layer 204 , the second dielectric layer 205 and the third metal layer 206 are set. Wherein, the microstrip coupling probe 207, the microstrip impedance transition section 208 and the microstrip output ports port 21-port 24 are all arranged on the first metal layer 202, the second metal layer 204 constitutes the microstrip ground plane, and the first dielectric layer 203 and the second dielectric layer 205 are provided with a plurality of through holes 2031, 2051, these through holes are surrounded by a geometric figure, these through holes can limit the elec...

Embodiment 2

[0056] In order to further improve the matching bandwidth of the rectangular waveguide port, in this embodiment Figure 1-3 Based on the shown rectangular waveguide-microstrip four-way power divider, a rectangular waveguide-microstrip six-way power divider is proposed.

[0057] Such as Figure 4 , Figure 5 , Figure 6 As shown, the six-way power divider has a rectangular waveguide input port port45, four microstrip output ports port41-port44 and two coplanar waveguide output ports port46-port47. The six-way power divider includes an input rectangular waveguide 401, a first metal layer 402, a first dielectric layer 403, a second metal layer 404, a second dielectric layer 405, a third metal layer 406, a third dielectric layer 407 and The fourth metal layer 408 . Wherein, the microstrip output ports port41-port44, the microstrip coupling probe 409, and the microstrip impedance transition section 410 are all arranged on the first metal layer 402, the second metal layer 404 co...

example

[0065] Taking the X-band four-way and six-way power splitters as an example, the rectangular input waveguide size is 22.86×10.16mm, the dielectric layer is made of Rogers 5880 dielectric board with a dielectric constant of 2.2, and the loss tangent of the dielectric layer is 0.009 . All output ports of the four-way and six-way power splitters have an impedance of 50 ohms.

[0066] According to the invention Figure 7 and 8 Dimensions in the X-band four-way power divider are: w 1 =2.48,w 2 =6.30, w 3 =20.94,a=36,a 0 =22.86,a 1 =26,b=30,b 0 =10.16,b 1 =13,d 1 =2.16,d 2 =4.28,d 3 =4.14, h 1 =1.016, h 2 =1.5,L s =1.016,L p =0.8, r 0 = 0.25. The size of the X-band six-way power splitter is: w 1 =2.48,w 2 =6.30, w 3 =20.94,w 4 =1.51,w s =8.53,a=36,a 0 =22.86,a 1 =26,b=30,b 0 =10.16,b 1 =13,d 1 =2.16,d 2 =4.05,d 3 =4.14,d s =2.95,h 1 =1.016, h 2 =1.5, h 3 =1.016, L s =0.508, L s1 =2.60,L p =0.8, r 0 =0.25,w f =2.54. The above numerical units are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com