Processing method of plate heat pipe

A processing method and technology of plate heat pipes, which are applied to heat exchange equipment and other directions, can solve the problems such as the decrease of the temperature average capacity of the radiator, the limitation of the heat dissipation capacity of the fins, and the poor heat transfer capacity of the substrate, so as to control the production cost, achieve good heat dissipation effect, Easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

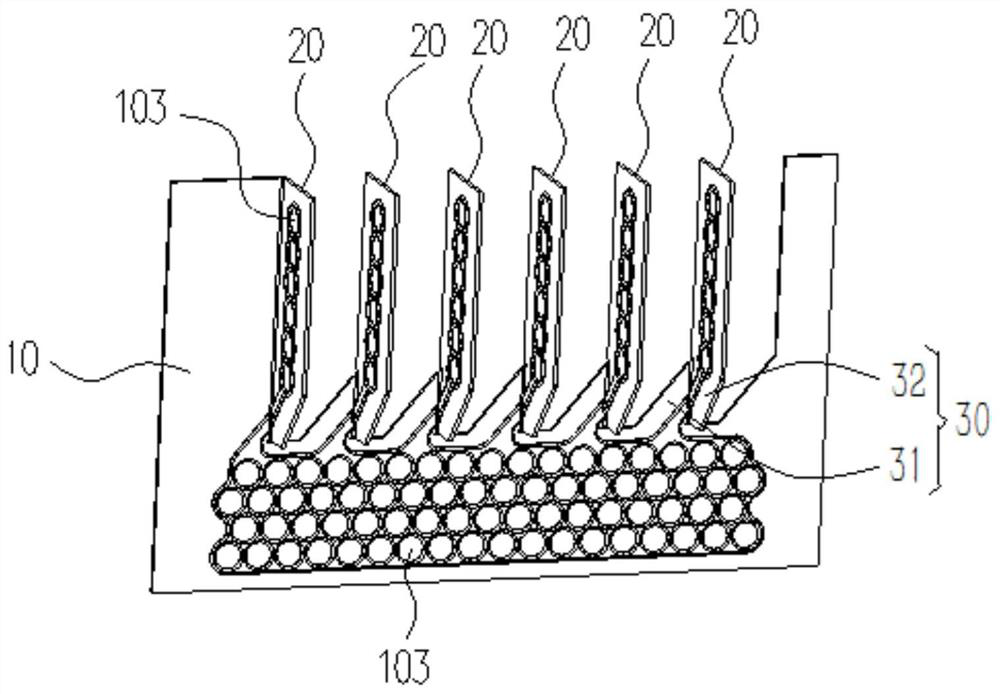

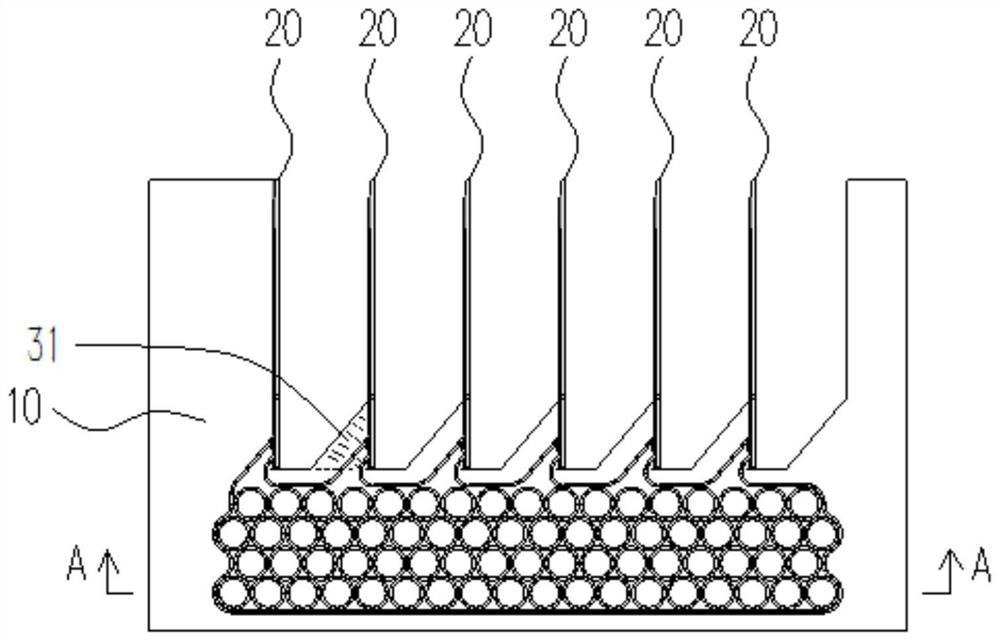

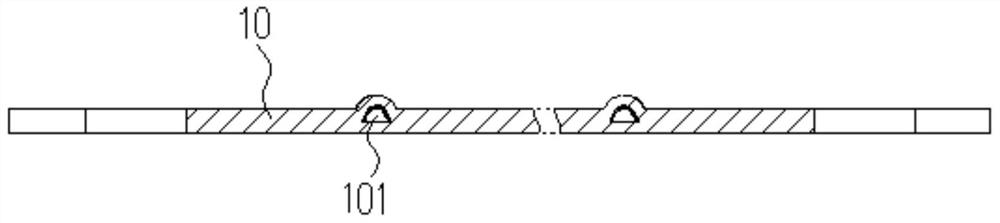

[0047] see Figure 1-Figure 5 , Embodiment 1 of the present invention provides a plate heat pipe for transferring and diffusing heat from a heat source (for example, electronic components or electronic equipment, etc.), the plate heat pipe includes a flat part 10 and a plurality of The fin portion 20, the flat plate portion 10 is provided with a first cavity 101, each fin portion 20 is provided with a second cavity 201, and each second cavity 201 communicates with the first cavity 101, The plate heat pipe is provided with a closed cavity (not shown in the figure), the closed cavity includes a first cavity 101 and a second cavity 201, and the closed cavity is filled with a phase change working medium (not shown in the figure). Shown), the fin portion 20 has a cooling effect. When working, the liquid phase-change working medium in the first cavity 101 absorbs heat from the heat source and vaporizes, and the gaseous phase-change working medium expands rapidly and fills the entir...

Embodiment 2

[0079] see Figure 10 The difference between the plate-type heat pipe provided in Embodiment 2 of the present invention and the plate-type heat pipe in Embodiment 1 is that in this embodiment, the isolated part 103 is omitted, and at this time, the first cavity 101 and the second cavity 102 can also be connected. It is connected, and constitutes a part of the closed cavity, which improves the temperature uniformity of the flat plate part 10 in contact with the heat source and the fin part 20 for heat dissipation, improves the heat dissipation effect, and can meet the heat dissipation requirements of the surface of high-power equipment. Moreover, compared with the first embodiment, the plate heat pipe of this embodiment is easier to process, thereby effectively controlling the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com