Steelmaking alloy and slag material automatic discharging and weighing putting device and method

An automatic feeding and feeding device technology, applied in the field of steelmaking and metallurgy, can solve the problems of high labor intensity for post workers, high labor intensity for operators, and inconvenient use of refining furnaces, so as to reduce market quality objections and improve the brand image of special steel , Facilitate the effect of cost accounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

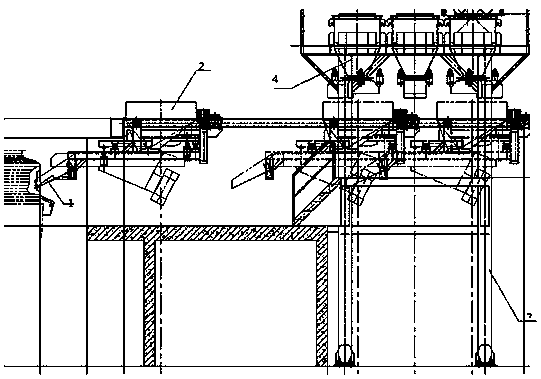

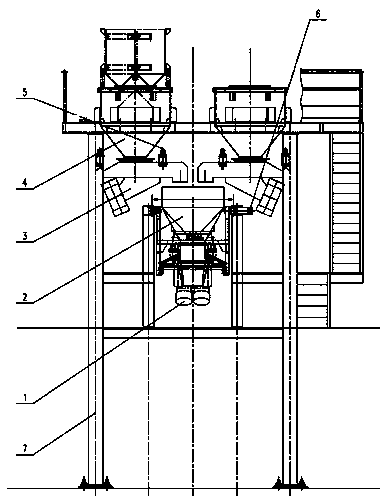

[0021] A steel-making alloy and slag material automatic feeding weighing and feeding device, including trolley vibrating feeder 1, weighing feeding trolley 2, silo vibrating feeder 3, silo 4, suspension mechanism 5, trolley track 6 And the steel structure support 7; the middle part of the steel structure support 7 is provided with a trolley track 6, the weighing feeding trolley 2 is arranged on the trolley track, the weighing feeding trolley 2 is provided with a weighing device, and the weighing and feeding trolley 2 matches There is a trolley vibrating feeder 1; a plurality of silos 4 are arranged on the upper part of the steel structure support 7, and a silo vibrating feeder 3 is provided under each silo 4, and the silo vibrating feeder 3 is set by a suspension mechanism 5 , the weighing feeding trolley 2 is provided with a feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com