Electronic transport layer ink and preparation method thereof

An electron transport layer and ink technology, applied in inks, household appliances, applications, etc., can solve the problems of difficulty in electrode injection and weak electron transport capability, and achieve enhanced electron injection capability, improved electron injection and transmission capability, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the electron transport layer ink of the present embodiment may further comprise the steps:

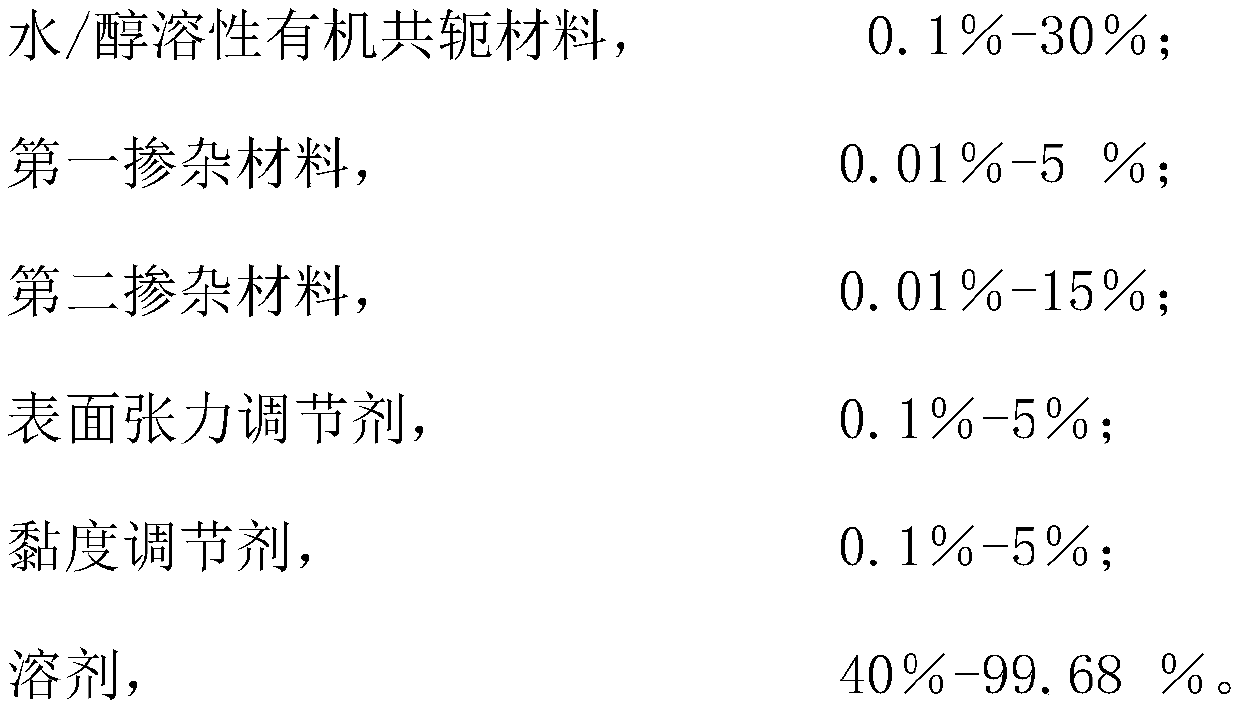

[0028] The components of the electron transport layer ink are provided according to the mass fraction; the components include 0.1% of the water / alcohol-soluble organic conjugated material according to the mass fraction; 0.01% of the first doping material; 0.01% of the second doping material; surface tension adjustment Agent 0.1%; viscosity regulator, 0.1%; solvent 99.68%.

[0029] The water / alcohol-soluble organic conjugated material, the first doping material, and the second doping material are dissolved in a solvent and mixed uniformly to obtain a first solution.

[0030] Adding the surface tension regulator and the viscosity regulator to the first solution, stirring at a temperature of 0°C-50°C for 0.5-24 hours until the surface tension regulator and the viscosity regulator are completely dissolved , to obtain a second solution; filter the second so...

Embodiment 2

[0032] The preparation method of the electron transport layer ink of the present embodiment may further comprise the steps:

[0033] The components of the electron transport layer ink are provided according to the mass fraction; the components include 15% of the water / alcohol-soluble organic conjugated material according to the mass fraction; 2.5% of the first doping material; 7.5% of the second doping material; surface tension adjustment Agent 2.5%; viscosity regulator, 2.5%; solvent 70%.

[0034] The water / alcohol-soluble organic conjugated material, the first doping material, and the second doping material are dissolved in a solvent and mixed uniformly to obtain a first solution.

[0035]Adding the surface tension regulator and the viscosity regulator to the first solution, stirring at a temperature of 0°C-50°C for 0.5-24 hours until the surface tension regulator and the viscosity regulator are completely dissolved , to obtain a second solution; filter the second solution ...

Embodiment 3

[0037] The preparation method of the electron transport layer ink of the present embodiment may further comprise the steps:

[0038] The components of the electron transport layer ink are provided according to the mass fraction; the components include 30% of the water / alcohol-soluble organic conjugated material according to the mass fraction; 5% of the first doping material; 15% of the second doping material; surface tension adjustment Agent 5%; viscosity modifier, 5%; solvent 40%.

[0039] The water / alcohol-soluble organic conjugated material, the first doping material, and the second doping material are dissolved in a solvent and mixed uniformly to obtain a first solution.

[0040] Adding the surface tension regulator and the viscosity regulator to the first solution, stirring at a temperature of 0°C-50°C for 0.5-24 hours until the surface tension regulator and the viscosity regulator are completely dissolved , to obtain a second solution; filter the second solution to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com