Organic light-emitting device and preparation method thereof

An electroluminescent device and electroluminescent technology, which is applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc. problem, to achieve the effect of improving reflection, improving electron injection ability, and avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

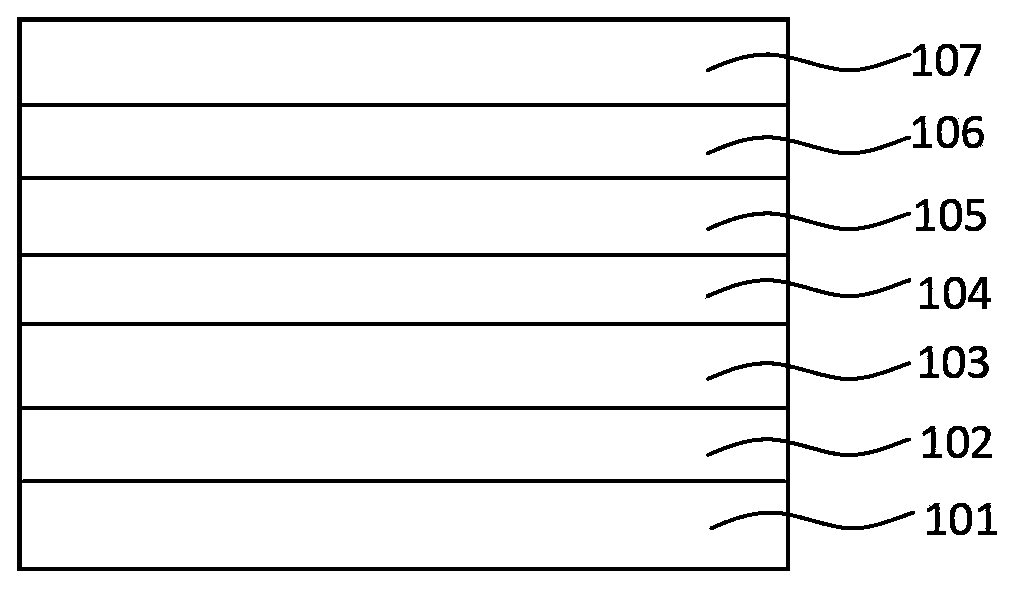

[0060] A method for preparing an organic electroluminescent device, comprising the following steps:

[0061] (1) Ultrasonic cleaning of the ITO glass substrate with detergent and deionized water for 15 minutes each to obtain a clean conductive anode glass substrate;

[0062] (2) In the high vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), the pressure is 8×10 -5 Under the condition of Pa, on a clean conductive anode glass substrate, thermally resistively evaporated hole injection layer, hole transport layer, light emitting layer, electron transport layer and electron injection layer in sequence;

[0063] Specifically, in this embodiment, the material of the hole injection layer is MoO 3 , with a thickness of 40nm; the material of the hole transport layer is TCTA, with a thickness of 40nm; the material of the light-emitting layer is Alq3, with a thickness of 10nm; the material of the electron transport layer is TAZ, with a thickness of 170nm...

Embodiment 2

[0069] A method for preparing an organic electroluminescent device, comprising the following steps:

[0070] (1) Ultrasonic cleaning of the AZO glass substrate with detergent and deionized water for 15 minutes each to obtain a clean conductive anode glass substrate;

[0071] (2) In the high vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), the pressure is 2×10 -3 Under the condition of Pa, on a clean conductive anode glass substrate, thermally resistively evaporated hole injection layer, hole transport layer, light emitting layer, electron transport layer and electron injection layer in sequence;

[0072] Specifically, in this embodiment, the material of the hole injection layer is WO 3 , with a thickness of 80nm; the material of the hole transport layer is NPB, with a thickness of 60nm; the material of the light-emitting layer is ADN, with a thickness of 5nm; the material of the electron transport layer is Bphen, with a thickness of 200nm; ...

Embodiment 3

[0077] A method for preparing an organic electroluminescent device, comprising the following steps:

[0078] (1) Ultrasonic cleaning of the IZO glass substrate with detergent and deionized water for 15 minutes each to obtain a clean conductive anode glass substrate;

[0079] (2) In the high vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), the pressure is 5×10 -5 Under the condition of Pa, on a clean conductive anode glass substrate, thermally resistively evaporated hole injection layer, hole transport layer, light emitting layer, electron transport layer and electron injection layer in sequence;

[0080] Specifically, in this embodiment, the material of the hole injection layer is V 2 o 5 , with a thickness of 20nm; the material of the hole transport layer is TAPC, with a thickness of 30nm; the material of the light-emitting layer is BCzVBi, with a thickness of 40nm; the material of the electron transport layer is TPBi, with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com