Transparent OLED alloy cathode, manufacturing method thereof and transparent OLED device

An alloy and cathode technology, which is applied in the field of OLED display and lighting, can solve the problems of unbalanced device positive load carrier injection, weak ability of cathode to emit electrons, easy oxidation or peeling, etc., so as to improve electron injection ability and easy film thickness The effect of controlling and reducing the difficulty of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

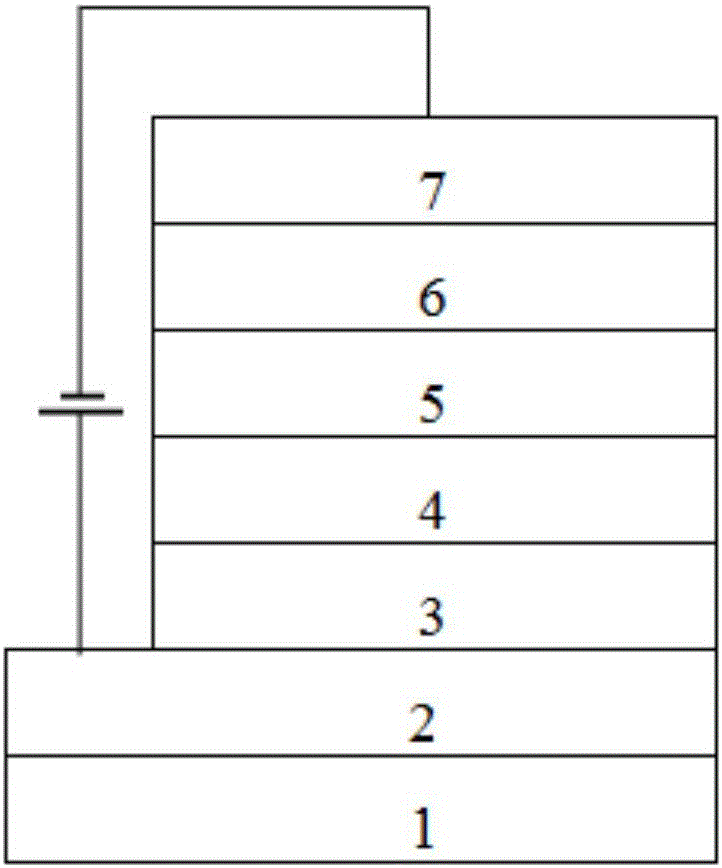

preparation example Construction

[0039] A method for preparing a transparent OLED alloy cathode includes the following steps:

[0040] Step 1: Preparation of Ag and Al raw materials: Weigh Ag and Al raw materials according to the mass ratio Ag: Al=75-80%: 25-20% by using an electronic balance of 1 / 10,000;

[0041] Step 2: Preparation of the quartz glass tube: cut off the required length of the quartz glass tube, and use the mixed gas of oxygen and liquefied gas to melt and seal one end of the quartz glass tube for use;

[0042] Step 3: Sealing of raw materials: Put the weighed Ag and Al raw materials into a quartz glass tube whose one end is closed, and while evacuating the quartz glass tube, use a mixture of oxygen and liquefied gas to melt and seal the other end of the quartz glass tube ;

[0043] Step 4. Preparation of alloy cathode: Put the sealed quartz glass tube containing raw materials into a high-temperature sintering furnace. The temperature of the high-temperature sintering furnace is raised to 850°C withi...

Embodiment 1

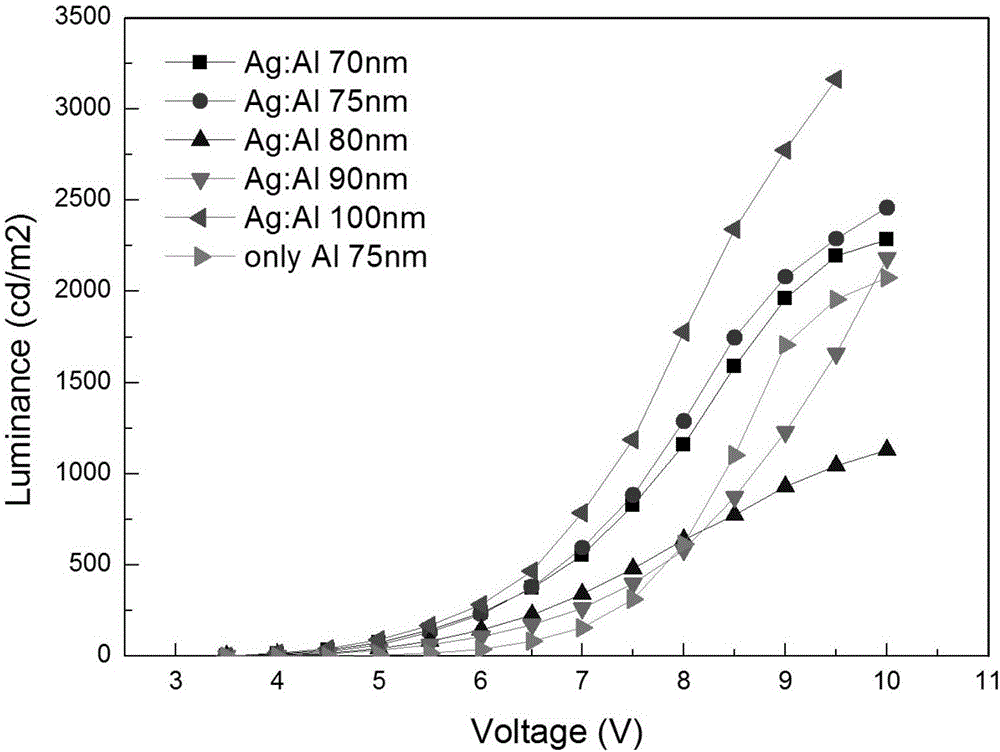

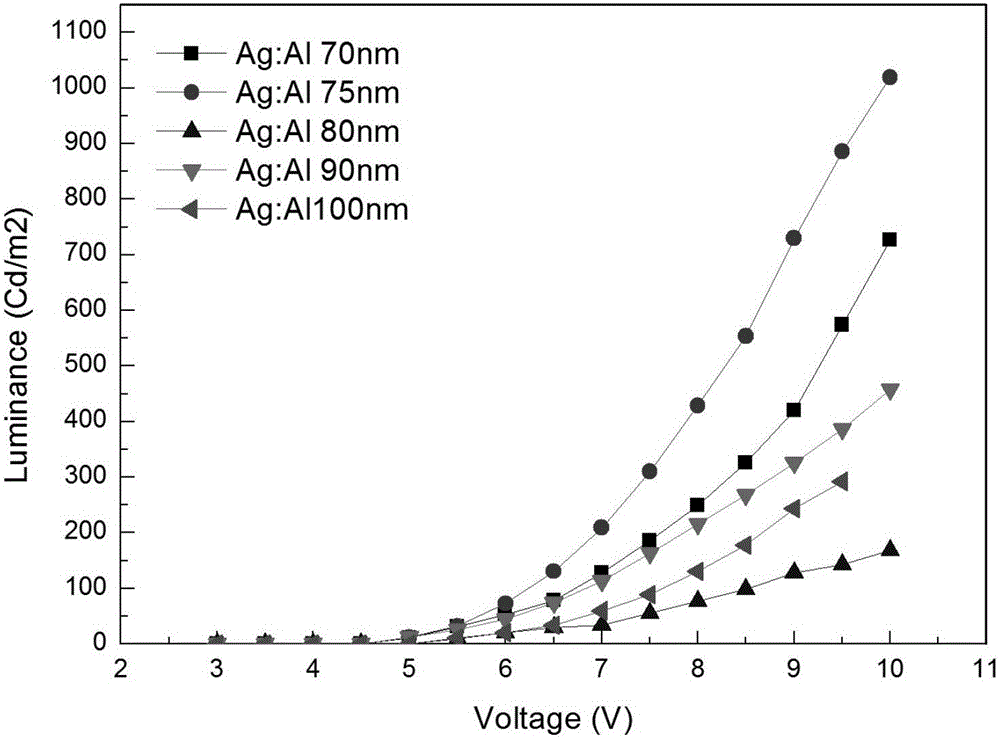

[0047] This embodiment is a transparent OLED alloy cathode, which includes 75% Ag and 25% Al. Among them, the work function of Al is 4.28 ev, and the work function of Ag is 4.26 ev. The vacuum melting method is used to melt in a quartz glass tube under vacuum conditions and then naturally cool to form.

[0048] The preparation process is as follows:

[0049] Step 1. Preparation of Ag and Al raw materials: Weigh the required Al wire and Ag particles in a mass ratio of Ag: Al = 75%: 25% with a one-ten thousand electronic analysis balance;

[0050] Step 2. Preparation of the reaction vessel: cut off the quartz glass tube of the required length, and use the mixed gas of oxygen and liquefied gas to melt and seal one end of the quartz glass tube for use;

[0051] Step 3. Sealing of raw materials: Put the weighed Ag and Al raw materials into a quartz glass tube whose one end is closed, and while evacuating the quartz glass tube, use the mixed gas of oxygen and liquefied gas to melt and seal...

Embodiment 2

[0055] This embodiment is a transparent OLED alloy cathode, which includes 75% Ag and 25% Al. Among them, the work function of Al is 4.28 ev, and the work function of Ag is 4.26 ev. The vacuum melting method is used to melt in a quartz glass tube under vacuum conditions and then naturally cool to form.

[0056] The preparation process is as follows:

[0057] Step 1. Preparation of Ag and Al raw materials: Weigh the required Al wire and Ag particles in a mass ratio of Ag: Al = 75%: 25% with a one-ten thousand electronic analysis balance;

[0058] Step 2. Preparation of the reaction vessel: cut off the quartz glass tube of the required length, and use the mixed gas of oxygen and liquefied gas to melt and seal one end of the quartz glass tube for use;

[0059] Step 3. Sealing of raw materials: Put the weighed Ag and Al raw materials into a quartz glass tube whose one end is closed, and while evacuating the quartz glass tube, use the mixed gas of oxygen and liquefied gas to melt and seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Work function | aaaaa | aaaaa |

| Work function | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com