Two-stroke gasoline engine cylinder

A gasoline engine and two-stroke technology, which is applied to cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of lack of economy and practicability, the inability to mold the throttle hole, and the limited harmful components in the exhaust gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

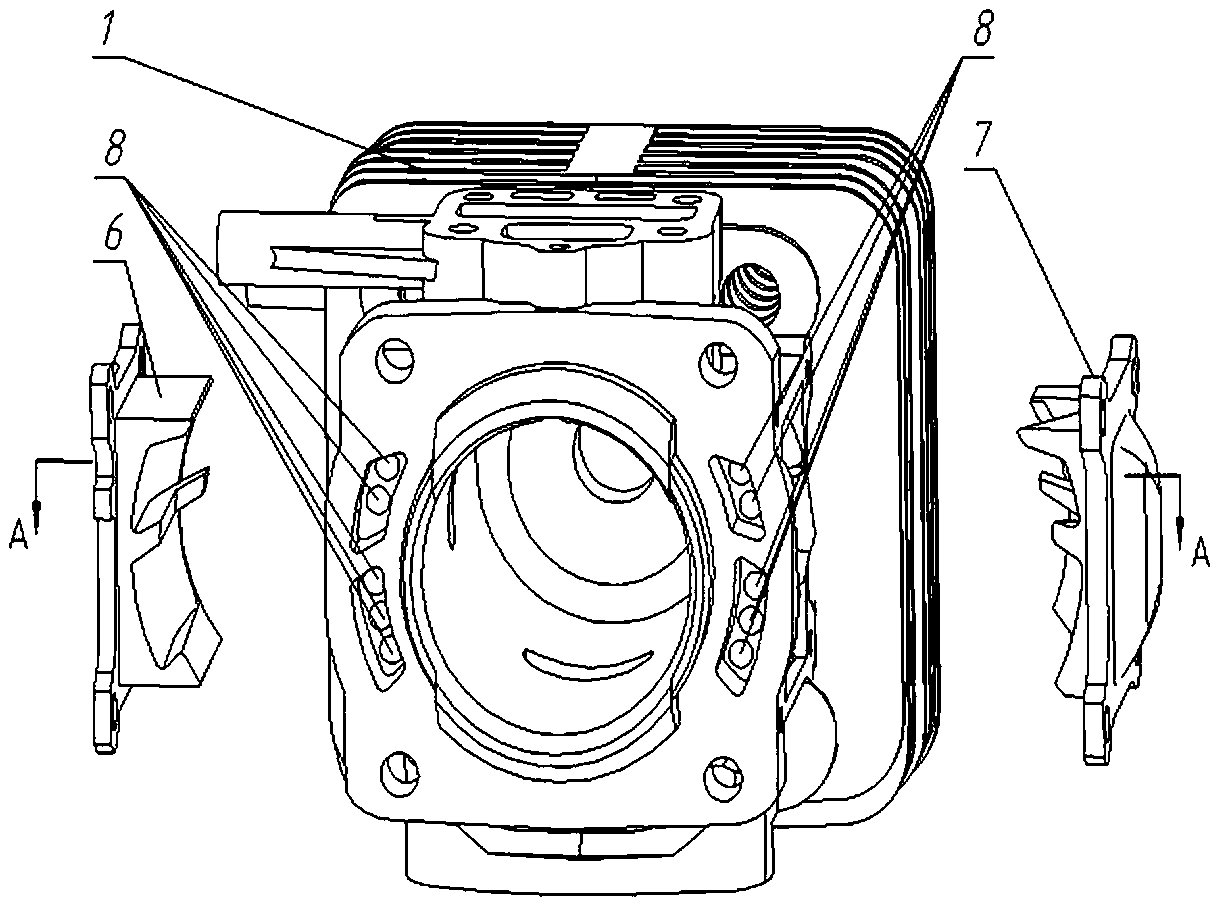

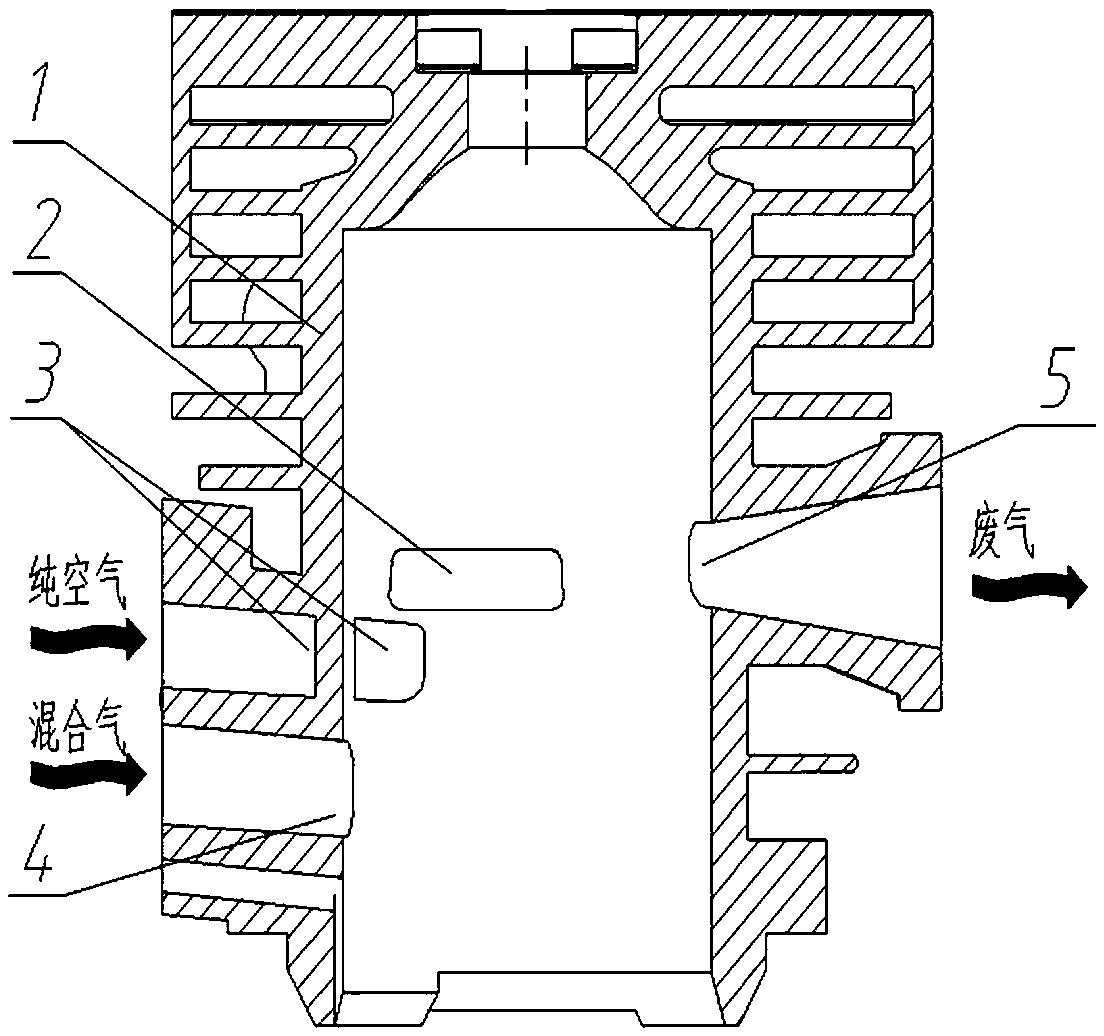

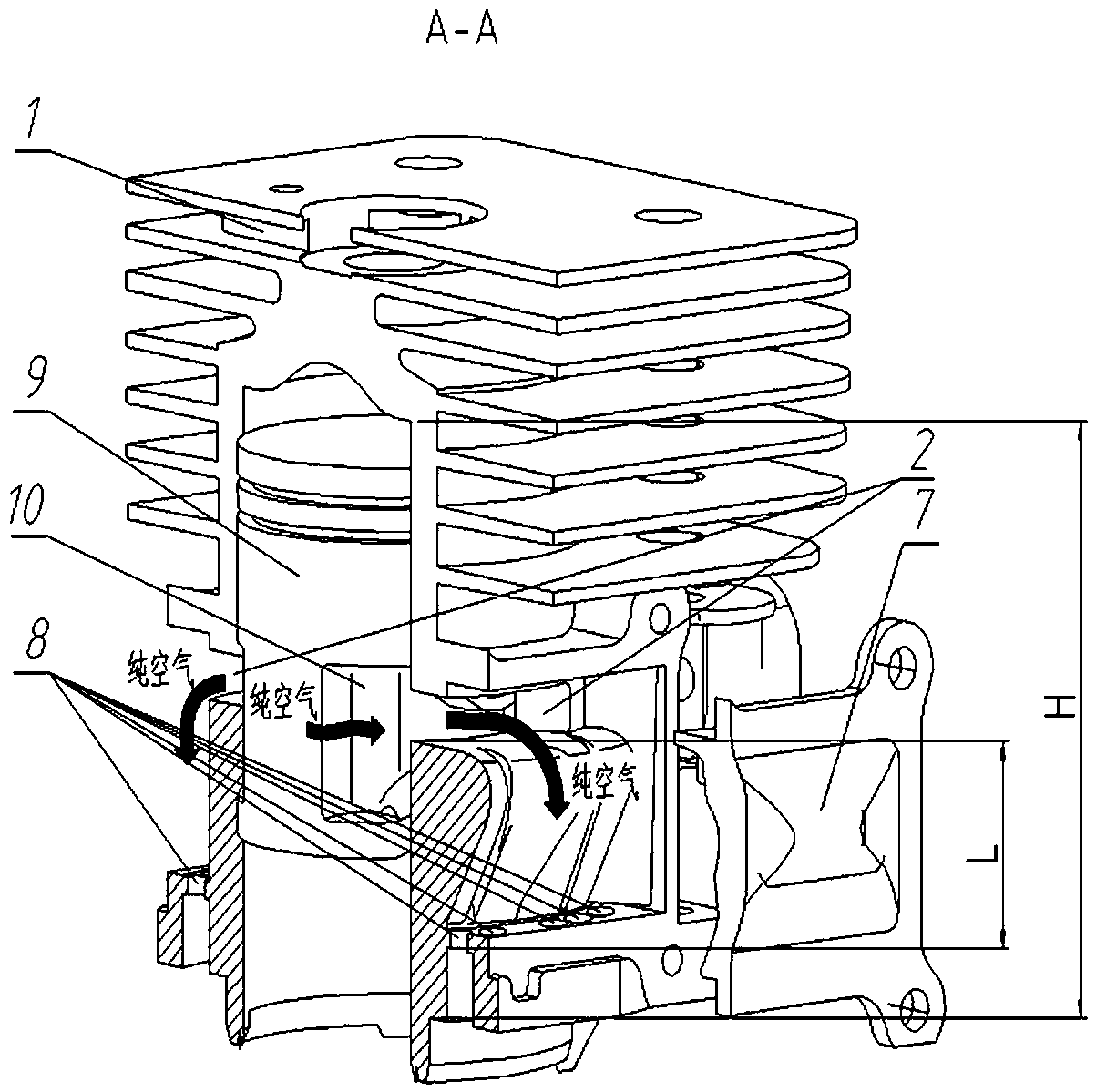

[0017] Such as Figure 1 ~ Figure 4 As shown, a cylinder block of a two-stroke gasoline engine, the cylinder body 1 is provided with a pure air intake port 3, a mixture gas intake port 4, two scavenging ports 2, an exhaust port 5, and a plurality of scavenging gas restriction holes 8. Preferably, the scavenging air restriction hole 8 is usually designed as a round hole, and can also be designed as a long hole, a square hole, or other shapes that can achieve the same function as required.

[0018] The piston 9 can reciprocate up and down along the axis in the cylinder body 1. The piston 9 is provided with a pure air passage 10 through which pure air can pass. The pure air passage 10 is usually designed as two symmetrical places on the piston 9, which are respectively connected to the cylinder. The pure air inlet 3 of the body 1, the cylinder body 1 and the side cover one 6 cooperate to form a pure air storage room one, and the cylinder body 1 and the side cover two 7 cooperate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com