A scavenging system for a two-stroke engine

A scavenging system and engine technology, which is applied in the field of scavenging systems, can solve the problems of two-stroke internal combustion engine exhaust gas containing a large number of harmful components, etc., and achieve the effects of saving fuel consumption, improving fuel economy, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

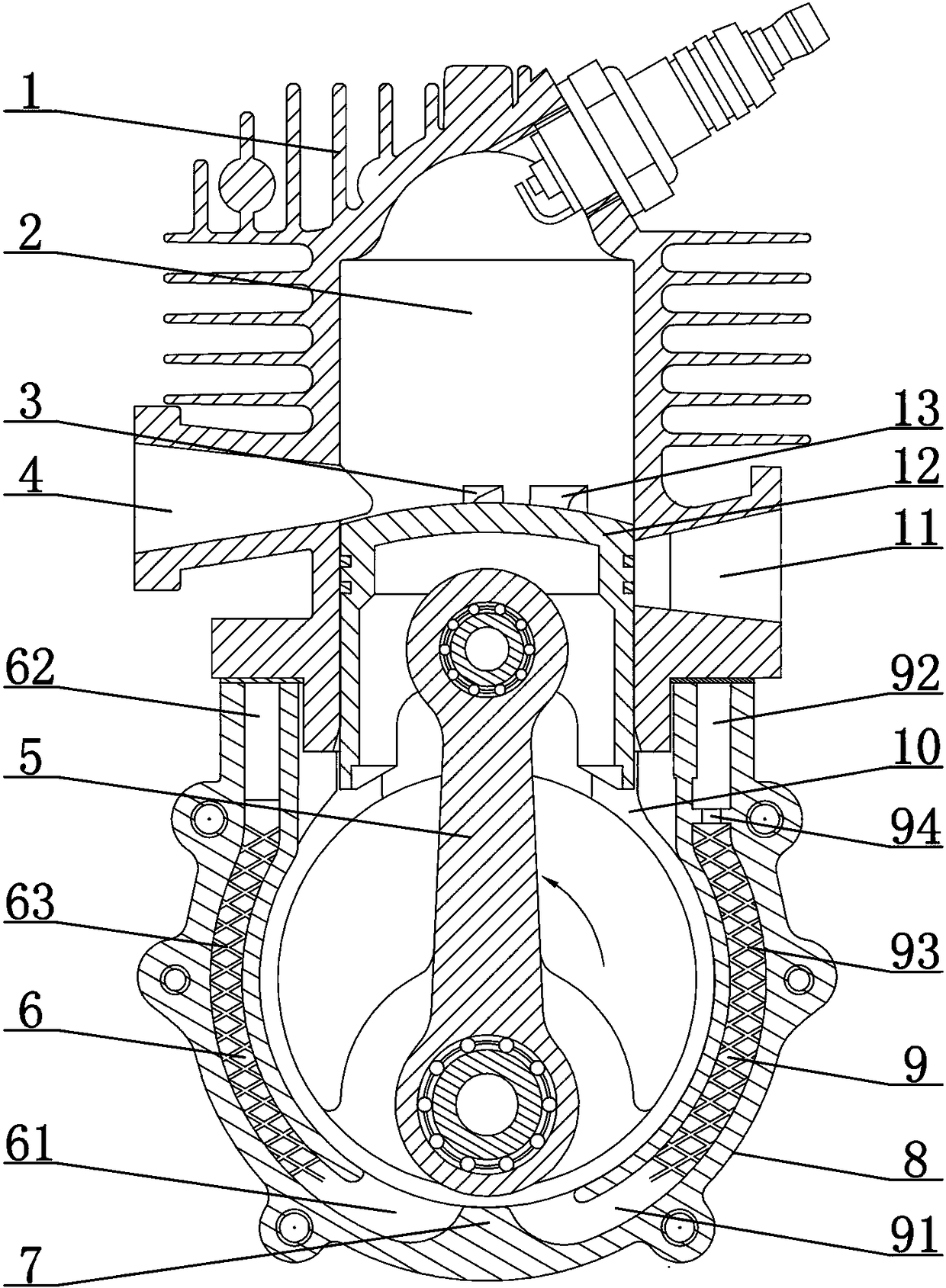

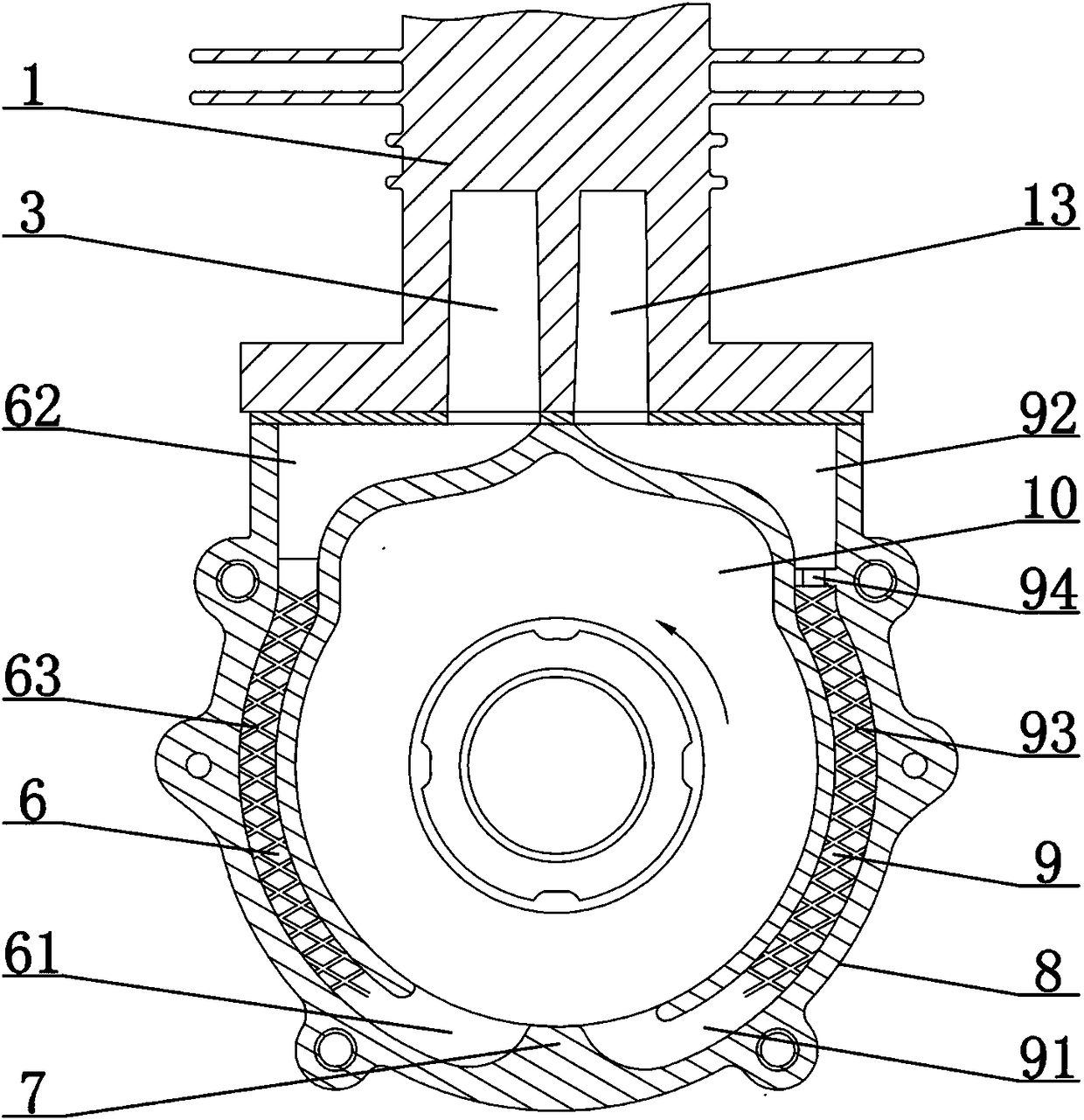

[0019] like figure 1 , figure 2 As shown, a scavenging system of a two-stroke engine includes a cylinder 1 with a combustion working chamber 2, a crankcase 8 with a crank chamber 10, a piston 12, and a crankshaft assembly 5, and the cylinder 1 is in phase with the crankcase 8. connected, the cylinder 1 is respectively provided with a fresh air mixture intake port 11 and an exhaust port 4, the piston 12 is located at the bottom of the combustion working chamber 2, and the crankshaft assembly 5 is located in the crank chamber 10 and Connected with the piston 12, the crank chamber 10 is also provided with a rich mixture scavenging passage 9 and a lean mixture scavenging passage 6, and the rich mixture scavenging passage 9 has a first air inlet 91, The first air outlet 92, the lean mixture scavenging passage 6 has a second air inlet 61, the second air outlet 62, the rich mixture scavenging passage 9, and the lean mixture scavenging passage 6 are in an arc type and are closely a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com