Internal combustion engine having scavenging control valve

A technology for controlling valves and internal combustion engines, which is applied to combustion engines, valve devices, mechanical equipment, etc. It can solve the problems of large amount of working oil, increased energy loss of working oil, and reduced engine performance, so as to achieve good engine performance and prevent warping and deformation , the effect of high scavenging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings. Unless otherwise specified, the dimensions, materials, relative positions and similar components described in the embodiments are only examples, and are not intended to limit the protection scope of the present invention.

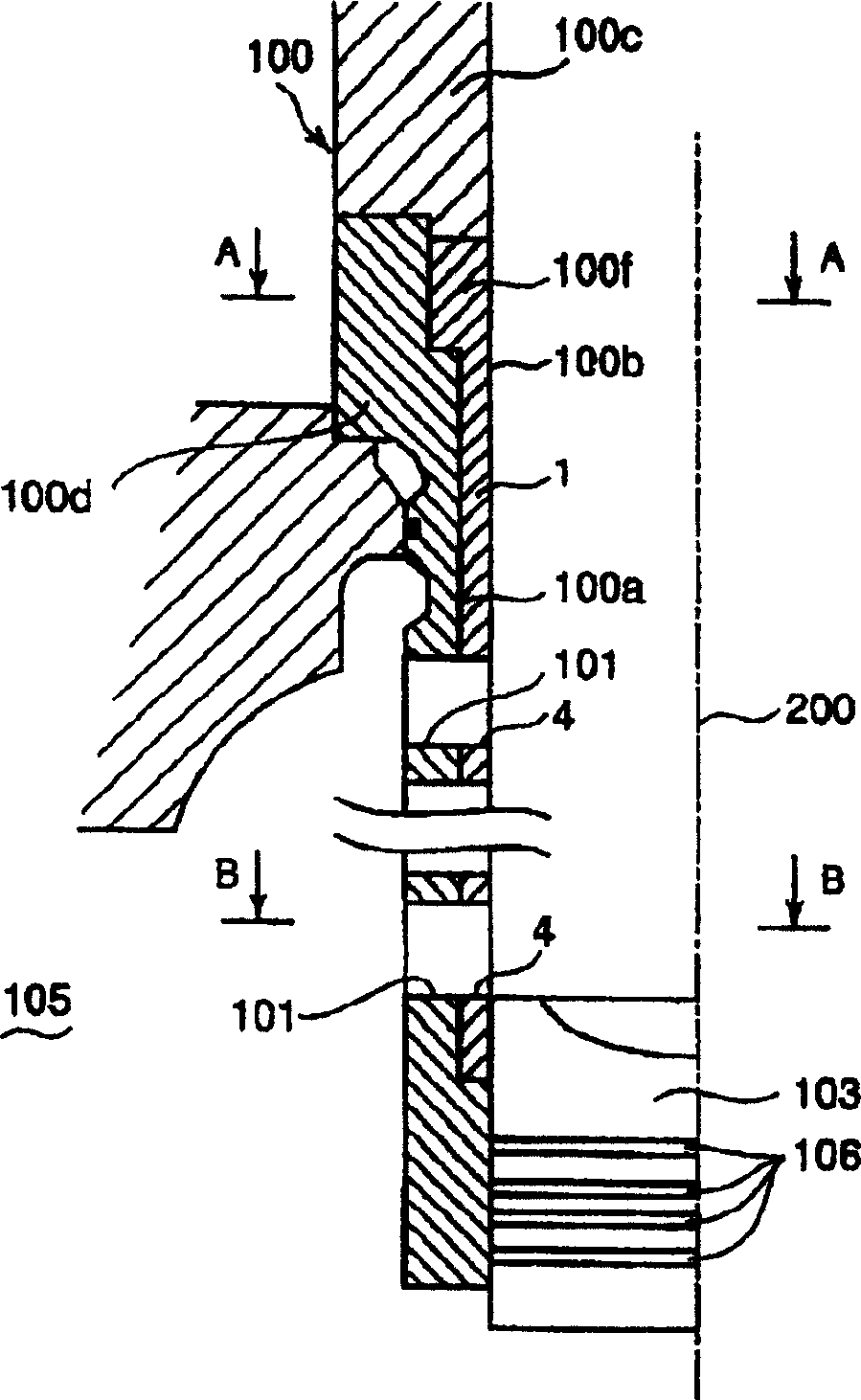

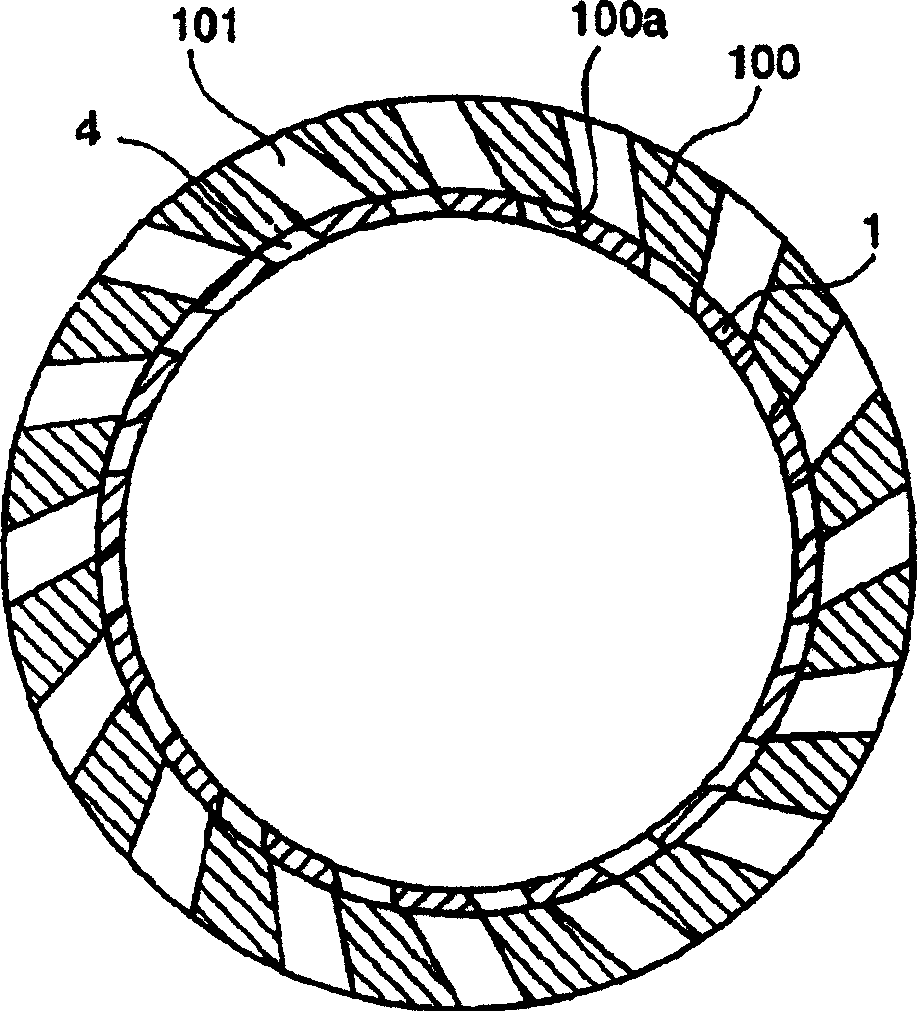

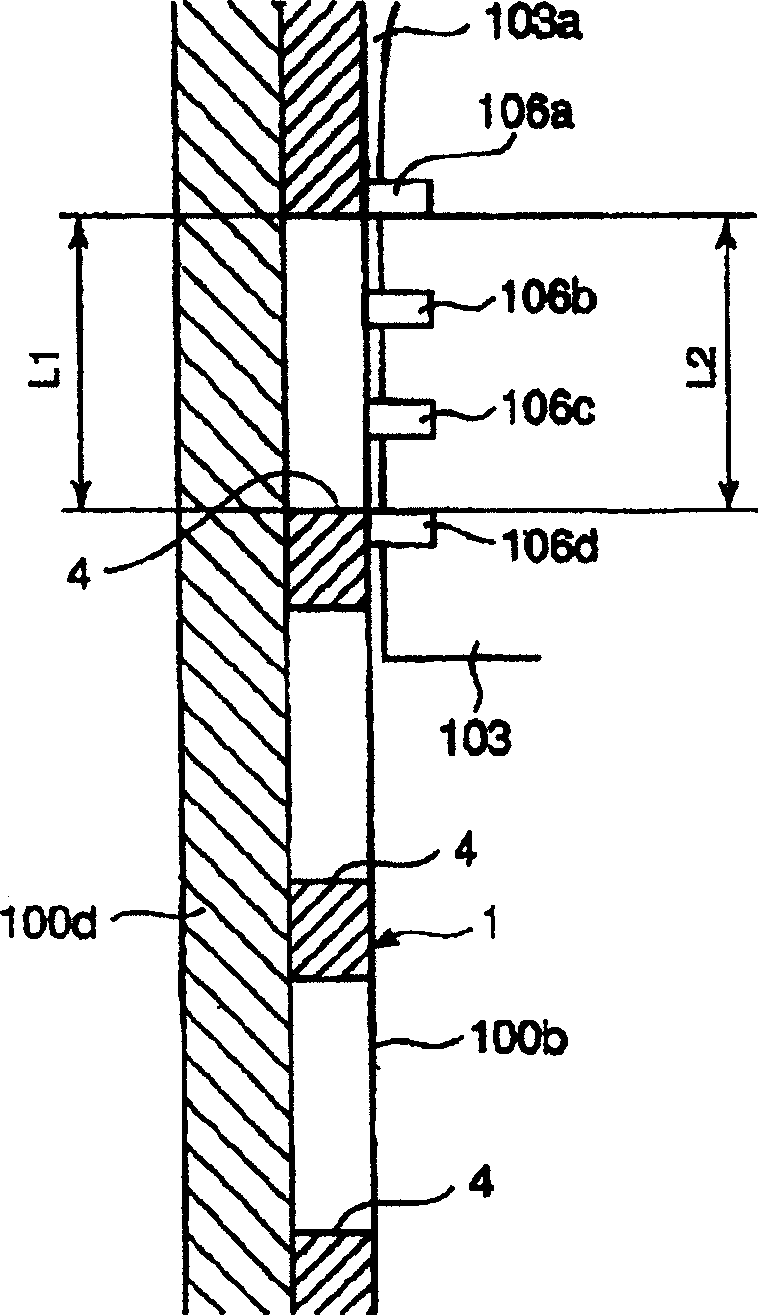

[0045] figure 1 It is a cross-sectional view of a large two-stroke engine along the cylinder centerline in the first to sixth embodiments of the present invention, wherein the air exchange port of the cylinder liner and the scavenging port of the scavenging control valve are shown, and figure 2 is along figure 1 Sectional view of midline B-B.

[0046] exist figure 1 and 2 Among them, reference numeral 100 is a cylinder liner composed of an upper sleeve portion 100c and an outer sleeve portion 100d, and 103 is a piston having a piston ring 106, which reciprocates in the upper sleeve portion 100c and the scavenging control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com