A device for collecting and treating waste from a grinding wheel grinder

A processing device and grinding machine technology, applied in grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as difficult discharge of waste residue, overflow of waste residue and smoke, and generation of a large amount of smoke, etc., to achieve Reasonable functional structure, easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

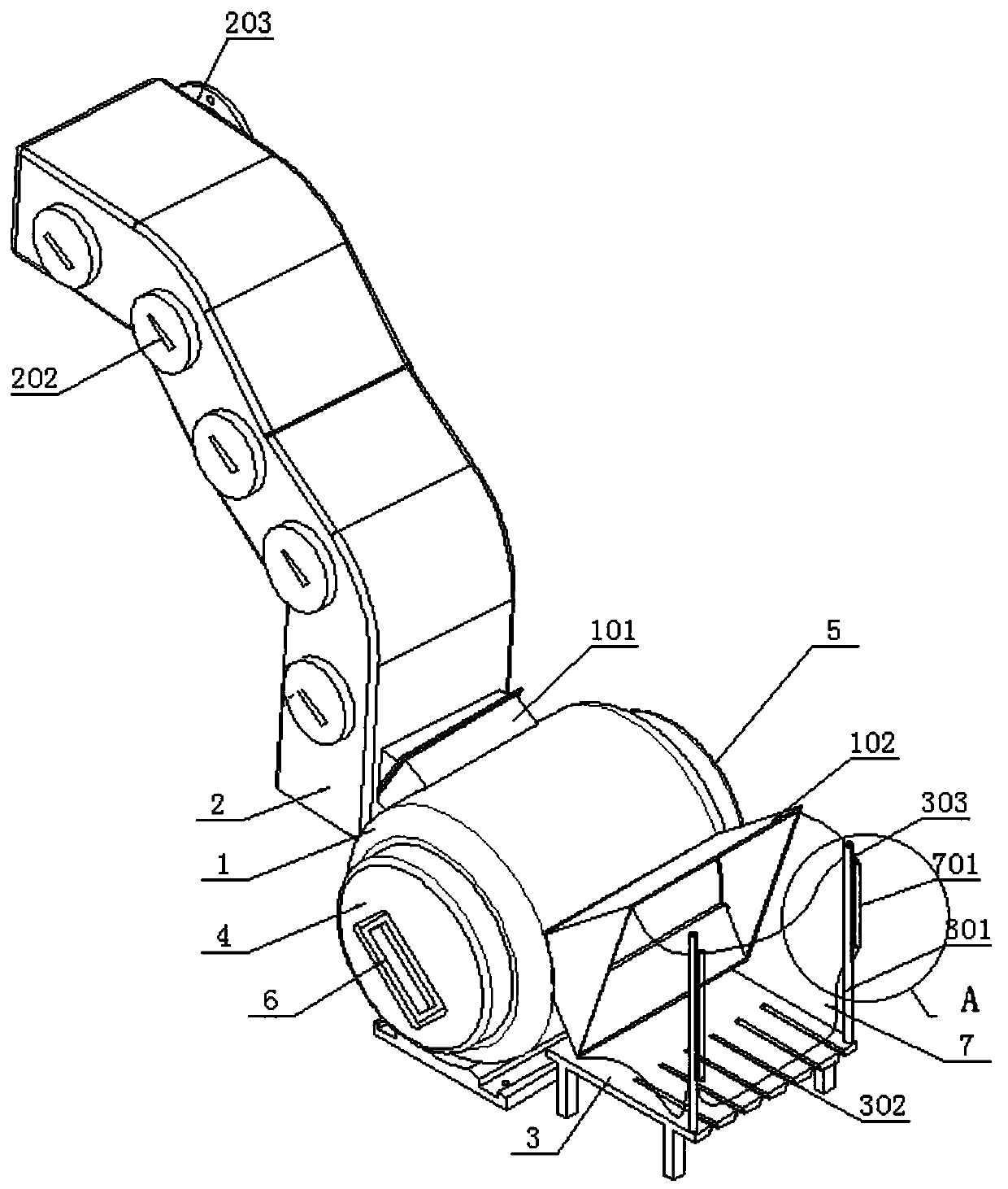

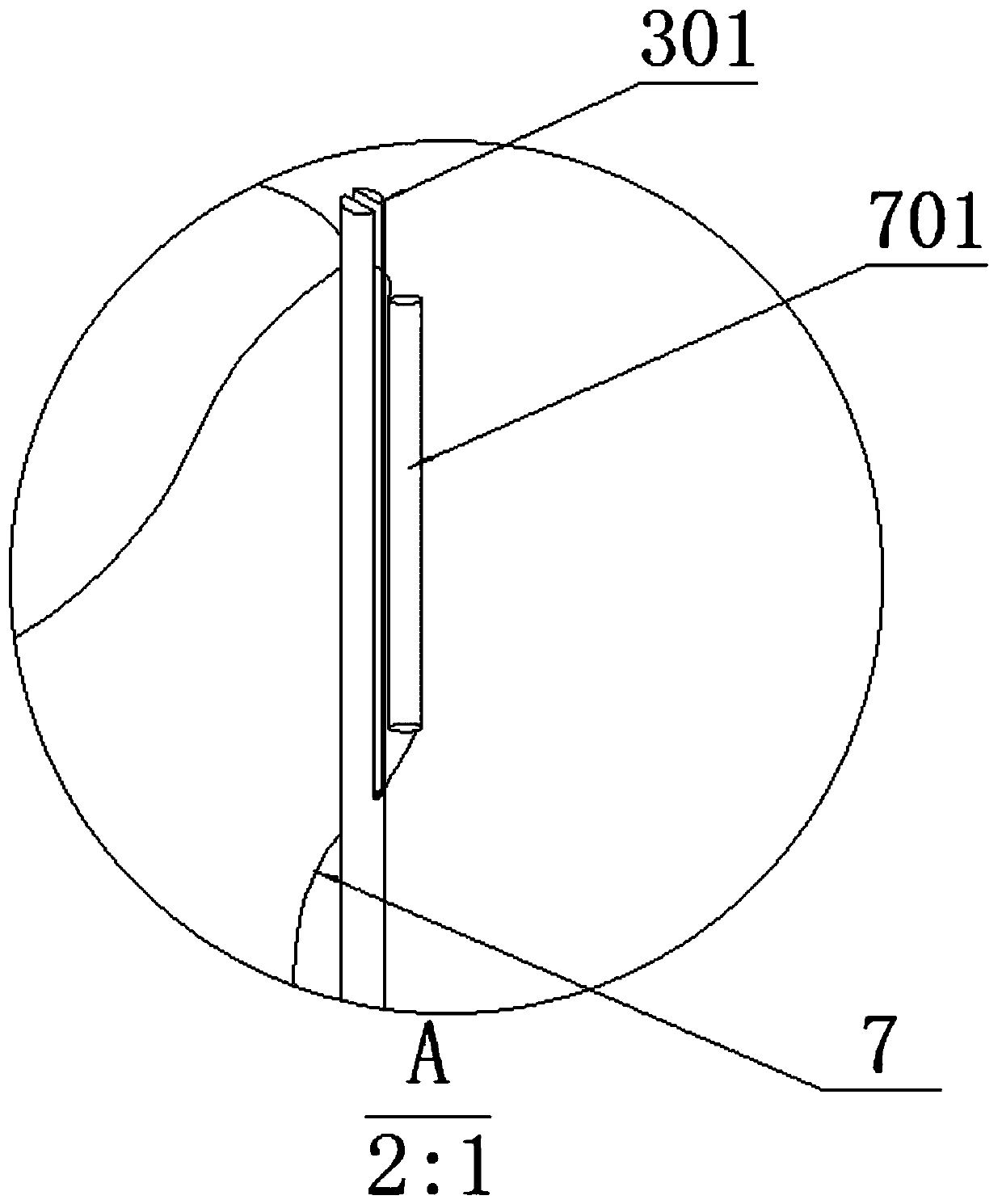

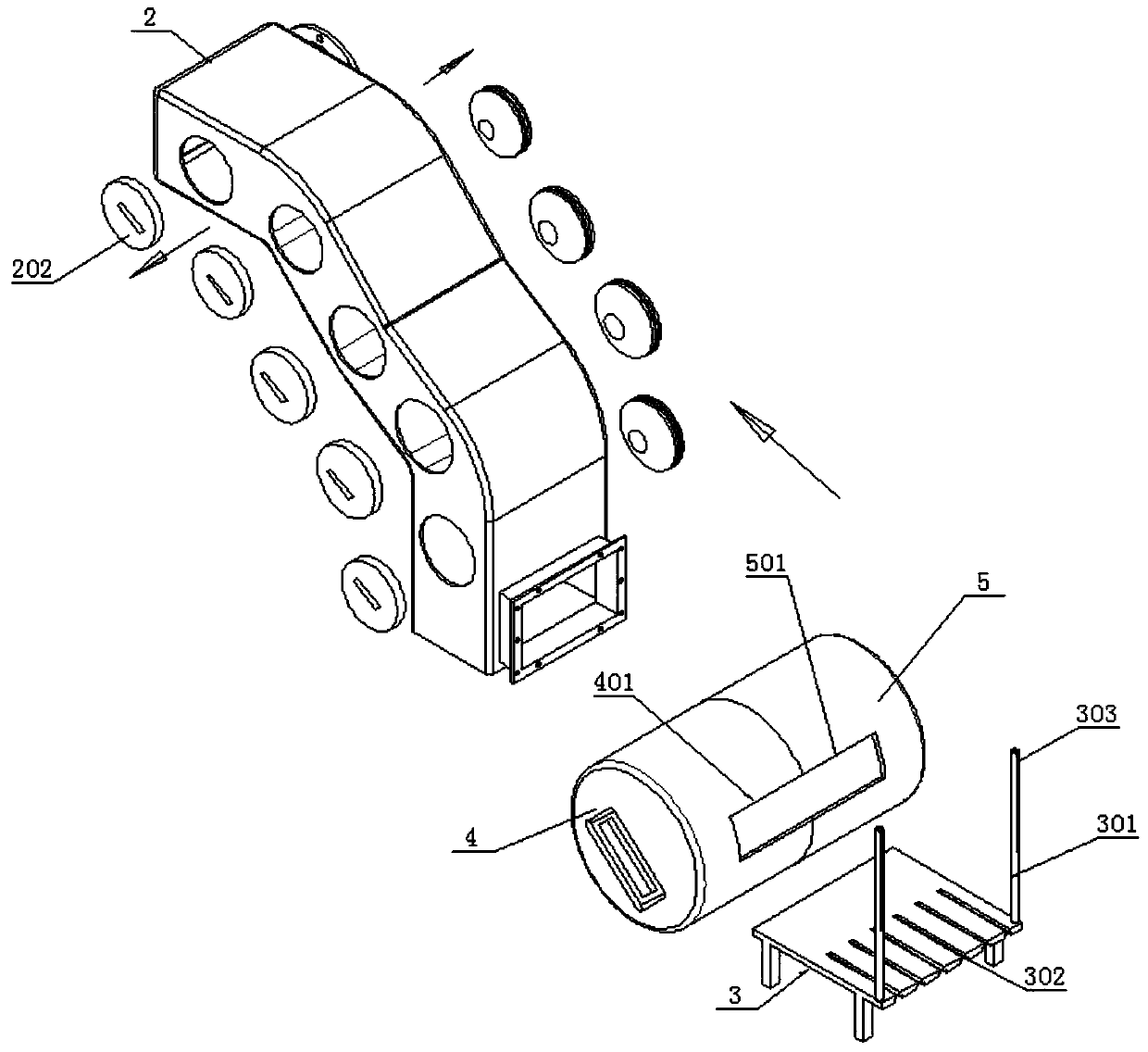

[0031] as attached figure 1 To attach Figure 9 Shown:

[0032] The present invention provides a grinding wheel grinder waste collection and treatment device, including: a collection seat 1, a dust outlet 101, a cover 102, a dust suction pipe 2, a mounting hole 201, a functional column 202, a flange interface 203, and a tool rack 3. Functional rod 301, fixed slot 302, through slot 303, first slag collection cabin 4, first slag inlet 401, first smoke outlet 402, first magnet 403, second slag collection cabin 5, second inlet Slag outlet 501, second smoke outlet 502, second magnet 503, handle 6, collection pocket 7 and hanging rod 701; one side of the collection seat 1 is provided with a dust outlet 101, and the other side is provided with a cover 102, and a dust suction pipe 2 is installed on the outside of the dust outlet 101; the tool rack 3 is a rectangular welded frame structure, and two function bars 301 are vertically installed on the right side of the top surface, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com