Earthwork standard room and application of earthwork standard room to slope re-greening

A technology of geocells and slopes, applied in infrastructure engineering, excavation, non-woven fabrics, etc., can solve problems such as weak soil fixing ability, lack of water absorption, water storage, and lack of water absorption and water storage capacity. Achieve the effects of improving land resource structure, prolonging water supply time, and improving water storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A geocell, the geocell is made of ecological non-woven fabric;

[0039] The raw material of the ecological non-woven fabric is polypropylene staple fiber, including short fibers of two specifications, respectively 6D*65mm and 5D*70mm; the mass ratio of the two kinds of short fibers is: 30% of 6D*65mm polypropylene staple fiber, 5D*70mm polypropylene staple fiber 70%.

[0040] The breaking strength of the above-mentioned polypropylene staple fibers is >4.5cN / dtex.

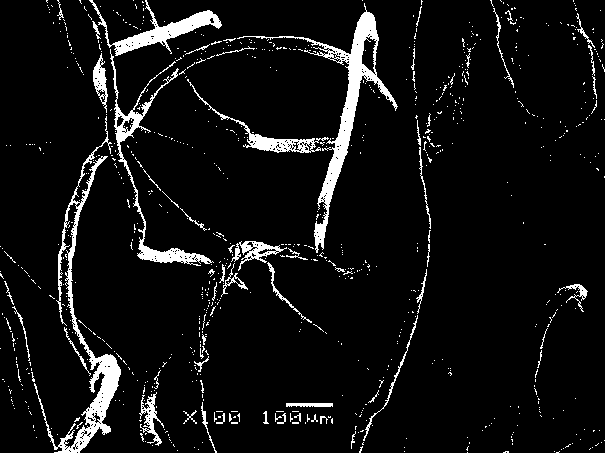

[0041] The above-mentioned polypropylene staple fibers are embracing each other to form a 3-dimensional porous fiber web, and finally a non-woven fabric with certain strength and stiffness is obtained by calendering.

[0042] The above-mentioned polypropylene staple fibers are mainly gray in color, including but not limited to black, green, white or a mixture of the above;

[0043] The above-mentioned ecological non-woven fabric: multi-layer fibers are stacked, and pores are formed by curling and cohesion b...

Embodiment 2

[0055] The raw material analysis experiment of embodiment 2 ecological non-woven fabrics

Embodiment 2-10

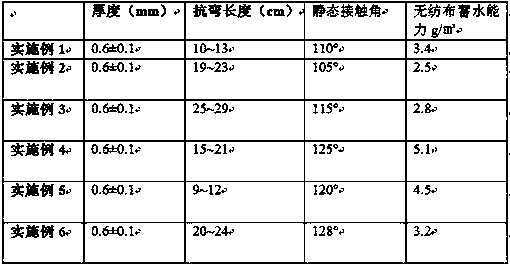

[0056] Same as the non-woven fabric preparation method of Example 1, only change the raw material specification and proportioning used, carry out Example 2-10;

[0057] The raw material ratio of embodiment 2-10 is as follows:

[0058] Example 2:

[0059] The specifications and ratio of polypropylene staple fiber used are: 40% of 4D*60mm polypropylene staple fiber and 60% of 6D*70mm polypropylene staple fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| tear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com